A179 Tubes

ASTM A179 tubes are designed for heat exchanger applications, providing efficient thermal transfer.

Heat exchanger tubes are the elements of the heat exchanger, which are placed in the cylinder and used for heat exchange between the two media.

Download PDFThe heat exchange tube is one of the elements of the heat exchanger, which is placed in the cylinder and used for heat exchange between the two media. Has high thermal conductivity and good isothermal properties. It is a device that can quickly transfer heat energy from one point to another with almost no heat loss, so it is called a heat transfer superconductor, and its thermal conductivity is thousands of times that of copper.

In addition to plain tubes, heat exchangers can also use a variety of enhanced heat transfer tubes, such as finned tubes, threaded tubes, spiral grooved tubes, etc. When the heat transfer coefficient on both sides of the inner diameter of the tube has a large difference, the fins of the finned tube should be arranged on the side with the lower heat transfer coefficient.

The commonly used dimensions of heat exchange tubes (outer diameter x wall thickness) are mainly Φ19mmx2mm, Φ25mmx2.5mm and Φ38mmx2.5mm seamless steel pipes and Φ25mmx2mm and Φ38mmx2.5mm stainless steel pipes. Standard pipe lengths are 1.5, 2.0, 3.0, 4.5, 6.0, 9.0m, etc. The use of small pipe diameter can increase the heat transfer area per unit volume, the structure is compact, the metal consumption is reduced, and the heat transfer coefficient is improved. It is estimated that by changing the heat exchange tube of the same diameter heat exchanger from Φ25mm to Φ19mm, the heat transfer area can be increased by about 40%, and the metal can be saved by more than 20%. However, the small diameter of the pipe has large fluid resistance, which is inconvenient to clean and easy to scale and block. Generally, large diameter pipes are used for viscous or dirty fluids, and small diameter pipes are used for cleaner fluids.

Commonly used materials are carbon steel, low alloy steel, stainless steel, copper, copper-nickel alloy, aluminum alloy, titanium, etc. In addition, there are some non-metallic materials, such as graphite, ceramics, polytetrafluoroethylene, etc. In the design, appropriate materials should be selected according to the working pressure, temperature and corrosiveness of the medium.

The arrangement of heat exchange tubes on the tube sheet mainly includes equilateral triangle, square and corner equilateral triangle and corner square. The equilateral triangle arrangement can arrange the maximum number of tubes on the same tube sheet area, so it is most commonly used, but it is not easy to clean the outside of the tube. To facilitate cleaning outside the tubes, tube bundles in a square or corner square arrangement can be used. The center distance of the heat exchange tube should ensure that the tube bridge (clearance distance between two adjacent tubes) has sufficient strength and width when the tube is connected to the tube sheet. When cleaning is required between the tubes, a channel for cleaning should also be reserved. The center distance of the heat exchange tubes should not be less than 1.25 times the outer diameter of the heat exchange tubes. The most commonly used center distances of the heat exchange tubes are as follows. Commonly used heat exchange tube center distance (mm).

| outer diameter | 10 | 12 | 14 | 16 | 19 | 20 | 25 | 32 | 35 | 38 | 45 | 50 | 57 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| center distance | 13~14 | 16 | 19 | 22 | 25 | 26 | 32 | 40 | 44 | 48 | 57 | 64 | 72 |

The central moment of the heat exchange tube is generally not less than 1.25 times the outer diameter of the heat exchange tube, which is mainly considered:During expansion, the elastic deformation ranges between the pipe holes do not intersect; when welding, leave a certain distance between the welds of each pipe section to reduce the welding stress between them. For slot welding around the tube hole on the tube sheet, the central moment of 125% of the outer diameter of the heat exchange tube is already the lower limit, and more than 132% of the outer diameter of the tube can be taken when conditions permit; this value is greater than or equal to 25mm. For heat pipes, it is convenient enough to clean the tube bundle, but for heat exchange tubes with an outer diameter of less than 25mm, in order to facilitate cleaning, the clear distance between the tubes should be 6mm.

The corrosion of the heat exchange tube definitely exists, but it is mainly concentrated in the pipe joints, and uniform corrosion is generally not the main problem; the heat exchange tube is a heat exchange element, if it is too thick, it will affect the heat exchange efficiency; the diameter of the heat exchange tube is very large. If it is small, the corresponding calculated thickness is also small, and the corrosion allowance is still there, but it is not as large as the shell, so its design service life is shorter than that of the shell; if the corrosion is serious, corrosion-resistant materials can be used. For example, some heat exchanger tubes are made of stainless steel, while the shells and heads of the shell side and tube side are all carbon steel; if the heat exchange tubes are corroded and penetrated, they can be replaced; The way to solve it, insist on using it until the next overhaul in order to replace the new heat exchanger.

The heat exchange tube is a pressure component. In addition to the material properties that it should have as a pressure component, the heat exchange tube itself has its own special requirements: high dimensional accuracy (outer diameter, wall thickness, length); material plasticity and toughness Good, especially for tube expansion, flanging and bending; welding performance of thin-walled tubes; low hardness value, generally lower than the hardness value of tube sheet; high test pressure.

The number of tubes in each process of the multi-tube process should be as equal as possible, and the relative error should be controlled within 10%, and the maximum should not exceed 20%.

The relative error is calculated as follows:

NCP : Average tube bundles for each tube pass

Nmin(max) : Minimum (maximum) number of tubes for each scale

There are four standard arrangements of heat exchange tubes: equilateral triangle, corner equilateral triangle, square, and corner square. Its arrangement is related to the flow direction of the fluid and the direction of the baffle notch. The direction of fluid flow is perpendicular to the notch of the baffle.To convert between equilateral triangles and corner equilateral triangles, it is necessary to rotate the piping by 90". If the tube is rotated 90", the arrangement of the heat exchange tubes is an equilateral triangle arrangement; if the tube is rotated 90", the arrangement of the heat exchange tubes is an equilateral triangle. To convert between square and corner square, you need to rotate the pipe by 45" (note that 45" is not 90" here). If the tube is rotated 90", the arrangement of the heat exchange tubes is still a square, and if the tube is rotated 45", the arrangement of the heat exchange tubes is a corner square; if the tube is rotated 90", the arrangement of the heat exchange tubes is still The corners are square, and if the pipe is rotated 45", the heat exchange tubes are arranged in a square form.

Tube Bundles for Air Coolers are key components in heat exchangers, specifically designed for cooling applications. These bundles consist of multiple tubes arranged in a bundle, which allows air to flow over the tubes, dissipating heat from the fluid inside. Typically made from materials like stainless steel, carbon steel, or copper alloys, these tube bundles are used in industries like power generation, petrochemical, and HVAC systems. They are designed for efficient heat transfer and can be customized in terms of tube length, diameter, and material to meet specific cooling requirements.

Alloy steel pipes are ideally suitable for chemical, petrochemicals, and other energy-related applications.

The alloy steel pipe adopts high quality carbon steel, alloy structural steel and stainless & heat resisting steel as raw material through hot rolling or cold drawn to be made.

Alloy steel can be used in process area where carbon steel has limitation such as

As an important element of steel products, alloy steel pipe can be divided into seamless steel pipe and welded steel pipe according to the manufacturing technique and tube billet shape.

Here you can see the common alloy steel grade that you will come across.

Why the application of alloy steel pipe is wider than others

There are many kinds of materials used for transport in industrial production. Specifically we will have more choices and it is not limited to the use of alloy steel pipe. But even in the face of more choices, many people tend to choose alloy steel pipe. People make their own choices will have their own reasons. This means the alloy steel pipe application has its own advantages. Compared with transmission lines made of other materials, after it meets the basic application requirements, its quantity is lighter. Then in the practical application of alloy steel pipe, it will have more advantages because of this. Besides its physical characteristic advantage, it also has economic advantages. The wide application of alloy steel pipe is with kinds of reasons. So in practical usage, we can exploit the advantages to the full, in this way can we get more profits in these applications of alloy steel pipe.

The transportation of kinds of gases or liquids in production needs to rely on alloy steel pipe. This shows that the actual role of alloy steel pipe application is important. High temperature resistant and low temperature resistant is the tolerance of temperature. In the practical application of alloy steel pipe, there will be many materials need to be transported. However their temperatures are not the same. So this can be the basic requirement to alloy steel pipe. It needs more corrosion resistance. Corrosion resistant material is the best material during transporting, because it is corrosion resistant. So it can be used in more occasions. And it is definitely very convenient for users.

Can be 100% recycled, environmentally friendly, energy-saving, resource conservation, national strategy, national policy to encourage the expansion of the field of application of high-pressure alloy pipe. Of alloy steel pipe total consumption accounted steel in the proportion is only half of the developed countries, to expand the field of use of the alloy steel pipe to provide a wider space for the development of the industry. The future needs of the average annual growth of China’s high-pressure alloy steel pipe long products up to 10-12%.

Alloy Steel pipe contains substantial quantities of elements other than carbon such as nickel, chromium, silicon, manganese, tungsten, molybdenum, vanadium and limited amounts of other commonly accepted elements such as manganese, sulfur, silicon, and phosphorous.

Our team of experienced sales specialists proudly partners with gas and chemical processors, power generation plants, oil refineries, and related industries to offer piping components and value-added services.

The biggest advantages of alloy steel pipe聽can be 100% recycled, environmentally friendly, energy-saving, resource conservation, national strategy, national policy to encourage the expansion of the field of application of high-pressure alloy pipe. Of alloy tube total consumption accounted steel in the proportion is only half of the developed countries, to expand the field of use of the alloy tube to provide a wider space for the development of the industry. According to the Chinese Special Steel Association alloy pipe Branch Expert Group, the future needs of the average annual growth of China’s high-pressure alloy pipe long products up to 10-12%.

Ultra-long heat exchanger tubes are essential components in large-scale industrial applications, such as power generation, chemical processing, and oil refining.

These tubes facilitate efficient heat transfer between fluids, contributing to the overall performance and energy efficiency of heat exchanger systems.

These tubes are commonly fabricated from materials like stainless steel, known for its corrosion resistance and durability. For instance, ASTM A688 TP304/304L ultra-long stainless steel U tubes are specifically designed for high-performance condenser equipment. Manufacturing processes such as cold rolling and cold drawing are employed to achieve precise dimensions and superior surface finishes. Surface treatments like annealing and passivation further enhance corrosion resistance and quality.

The design of ultra-long heat exchanger tubes involves several critical factors:

Ultra-long heat exchanger tubes are integral to various industries:

A tubular heat exchanger (THE) is used to warm or cool a product by exchanging heat between the process fluid and a service fluid, which is typically water, ice water, glycol or steam. The hot or cold service fluid flows around the tubes within the THE and heat is transferred between the product and the media.

A heat exchanger tube is a component of a heat exchanger that is responsible for transferring heat between two fluids. It is typically a long, hollow tube made of a highly conductive material such as metal, often stainless steel or copper. The purpose of the heat exchanger tube is to allow for the efficient exchange of thermal energy between the two fluids without any mixing or direct contact between them. One fluid flows inside the tube, while the second fluid flows around the outside of the tube. As the two fluids pass each other, heat is transferred from the hotter fluid to the cooler fluid through the walls of the tube. Heat exchanger tubes are widely used in various industrial applications for heating, cooling, or condensing fluids.

Based on thermal modeling comparisons using HTRI software, copper and copper/nickel are typically the most conductive material available for exchanger tubes. Carbon steel, stainless steel, and higher alloys are slightly less efficient, but all perform similarly.

There are different types of tubes that can be used for heat exchangers, and the best type depends on the specific application and requirements. Some common types of tubes used in heat exchangers include:

The choice of the best tube material for a heat exchanger depends on factors such as the fluid being processed, operating temperature and pressure, corrosion resistance requirements, thermal conductivity, cost considerations, and more. Therefore, it is essential to consult with a heat exchanger designer or engineer to determine the most suitable tube material for a specific heat exchanger application.

Heat exchanger tube is a device which is used to transfer heat from one medium to another for both cooling and heating processes. It separates the medium which is being used. Heat is transferred through these exchanger tubes by the conduction process. Mediums can be liquid, vapor, or gas. For example, an air-cooled heat exchanger uses air to cool a liquid and a shell & tube heat exchanger is for passing fluids.

Heat exchanger tubes are commonly used in various industries such as chemical processing, power generation, and refrigeration applications.

Heat exchanger tubes can be made from a variety of materials, including carbon steel, stainless steel, titanium, copper, and others, depending on the type of fluid being used and the operating conditions.

Some of the key features and properties of heat exchanger tubes include:

Heat exchanger tubes can come in a variety of shapes and sizes, including straight tubes, U-shaped tubes, and spiral tubes. They can be manufactured using various processes, such as seamless or welded, depending on the application requirements.

In summary, heat exchanger tubes are an essential component in heat exchangers used in various industries. They must be designed to have high thermal conductivity, good corrosion resistance, resistance to fouling, and good strength and durability to maintain efficient heat transfer between two fluids.

Heat exchange tubes are intended for heating or cooling process fluids, they are for example suitable for closed circuit cooling of electrical equipment using demineralised water and for cooling water soluble oil solutions in quenching tanks.

The former is suitable for heat transfer and vibration occasions without phase change, and the latter is suitable for reboiling, condensing heat transfer and vibration-free general occasions. The heat exchanger pipe shall be able to withstand certain temperature differences, stress and corrosion resistance. The length of the heat exchange tube is generally 1.0m, 1.5m, 2.0m, 2.5m, 3.0m, 4.5m, 6.0m, 7.5m, 9.0m, 12.0m. The material of the pipe can be carbon steel, stainless steel, aluminum, copper, brass and copper-nickel alloy, nickel, graphite, glass and other special materials, also often used composite pipe. In order to expand the area of effective heat transfer tube at the same time maximize the tube side heat transfer coefficient, heat exchange tube processing or in tube inserted into the internal and external surfaces of the disturbed flow components, producing fluid turbulence the inside and outside at the same time, commonly used such as rough surface tubes, finned tube, the supporting pipe, inside the plug-in type, etc.

Heat exchanger Tubes are used in all types of process industries. Characteristic requirements are: bead worked weld, fixed lengths and extensive testing. In order to meet the demand for rapid delivery, we have a strip stock with both standard and special grades of steel in the most common thicknesses.

We supply both seamless and welded tubes which meet the requirements for shell and tube heat exchangers:

Size range 6.35mm - 76.2mm OD x 0.91mm – 3.25mm wall thickness

Heat exchanger tubes are supplied in Standard Wire Gauge (SWG) or Birmingham Wire Gauge (BWG)

Popular grades: 1.4306 (304L), 1.4404 (316L)

Whether your application requires seamless or welded stainless steel tubing, you can always count on consistent, high quality tubing manufactured by our specialists at Sunny Steel. Many of the world’s leading heat exchanger manufacturer’s turn to us for their tubing needs. Applications include:

We offer quick turnaround as well as specialty and nickel alloys.

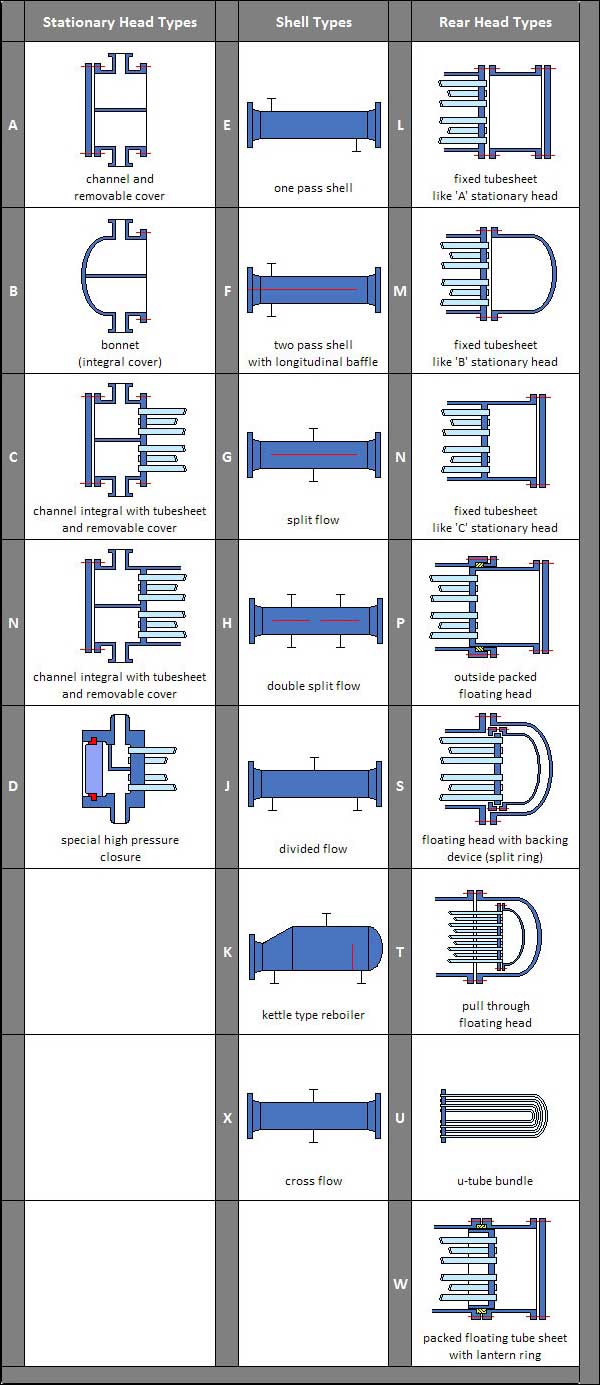

Shell-and-tube designs incorporate fixed or floating tubesheets, fixed or removable tube bundles and expansion joints as needed to create an effective heat transfer vessel. Gain a better understanding of the TEMA types to improve your selection process.

Among the most common types of heat transfer equipment used in industrial applications are the various configurations of shell-and-tube heat exchangers. Suitable for a range of pressure and temperature conditions, shell-and-tube heat exchangers can be robust enough to handle corrosive or even lethal fluids.

The shell-and-tube heat exchanger design allows heat transfer between two independent, pressurized chambers through the walls of the tubes. The design consists of an array of tubes, which is connected on each side to a flat plate called a tubesheet. The tubesheet also separates the shell and tube sides of the exchanger. Baffles on the outside of the tubes direct the flow of the shell-side fluid back and forth across the tubes to promote heat transfer. The process fluid can flow through either the shell or tube side, with the opposite side typically acting as the service side (usually a heating or cooling medium). The exchanger also can have a process fluid on both sides.

For most shell-and-tube heat exchanger types, the first step in designing an exchanger for a specific process is thermal design. Given the process conditions and heat transfer requirements, the thermal design determines the exchanger’s size, shape, number and size of tubes, number of baffles and baffle pitch, etc. Other factors considered at this stage include allowable pressure drop through the exchanger, any space constraints on the unit, the potential fouling of the unit and any resulting flow-induced vibration from the proposed design.

After the exchanger size is determined by the thermal design, a mechanical design is performed. This step determines the thickness of all parts as well as welding details required for the temperature and pressure conditions.

Many different configurations of shell-and-tube heat exchangers are available. There are advantages and disadvantages to each design, depending on factors such as process and thermal requirements, available space, financial budget and cleaning requirements. This article provides information on several of the most widely used configurations and briefly discusses some of the issues to consider when planning for and selecting a heat exchanger configuration.

The Tubular Exchanger Manufacturers Association, or TEMA, publishes a standard that establishes design, fabrication, tolerances, installation and maintenance of shell-and-tube type exchangers. This standard and the ASME code are the main standards used to design and fabricate exchangers along with any applicable customer specifications. The TEMA standard also defines the classes and main configuration styles of exchangers.

Because of the number of variations in mechanical designs for front and rear heads and shells, and for commercial reasons, TEMA has designated a system of notations that correspond to each major type of front head, shell type and rear head. The first letter identifies the front head, the second letter identifies the shell type and the third letter identifies the rear head type.

Removable bundle exchangers give the customer the ability to replace the tube bundle without replacing the shell or Bonnets. They are generally less cost effective than non removable designs.

BEU/AEU- U Bundle Exchangers are generally the most cost effective design style of removable bundle exchanger. Tubes may be water blasted, steam or chemically cleaned. These units must have an even number of tube passes, sometimes limiting their applicability to a service(e.g. they generally can not be used when a temperature cross occurs).

CEU- This design has the tubesheet welded to the Bonnet. You can remove the bundle from the shell, however to replace the bundle, the inlet Bonnet is included or you must cut off the tubesheet. Tubes may be chemically cleaned, water blasted or steam cleaned.

BEW/AEW- These are straight tube units with one floating head and one stationary head. The floating head is generally sealed with an O-Ring. These units are most often used as oil coolers or air coolers. Cleaning can be performed by either a chemical, mechanical method, water blast or steam cleaning.

AEP/BEP- These are straight tube units with one inside packed floating head and one stationary head. The floating head is generally sealed with packing. These units are most often used as intercoolers and aftercoolers with the gas on the tube side. They are also the most common style for oxygen service exchangers. These units have been used in services with tube side design pressures in excess of 2000 PSIG.

TEMA, Tubular Exchanger Manufacturers Association

AES/AET- These units are the most expensive of the removable bundle designed units. The floating head is internal to the shell. Tubes can be cleaned mechanically , chemically, water blasted or steam cleaned. The design of these units forces an even number of tube side passes therefore they suffer the same service restrictions as U bundles. Although in theory one pass unit can be designed, this is rarely done. These units are generally used in services where U bundles are not desired and the service may be too corrosive/damaging to the packing used in AEP/BEP units.

These types of units are often used in high pressure services and services where you wish to avoid leakage problems at gasketed joints. Another advantage is that they are generally more cost effective than removable bundle designs.

NEU- The most cost effective design available. The tubesheet is welded to both the shell and Bonnet. There is no access to the shell. Tubes may be chemically cleaned, water blasted or steam cleaned from inside only. These units are commonly used in high pressure services (such as feedwater heaters), where process conditions allow for even pass exchangers.

NEN- Tubesheets are welded to both the Shell and Bonnets. Access to the tubes is through covers on the channels. These units are favored in very high pressure designs as their construction minimizes the tubesheet thickness and number of high pressure retaining flanges.

AEM/BEM/AEL-SHELL side is completely welded up, however, the Bonnets are removable. Chemical, mechanical, and water blast cleaning of the tubes is possible, however you do not have access to the shell.

You should avoid using Steam cleaning on a fixed tube sheet unit unless the unit has a shell side expansion joint. The steam will cause the tubes to expand and pull out of the Tube Sheet causing failure at startup.

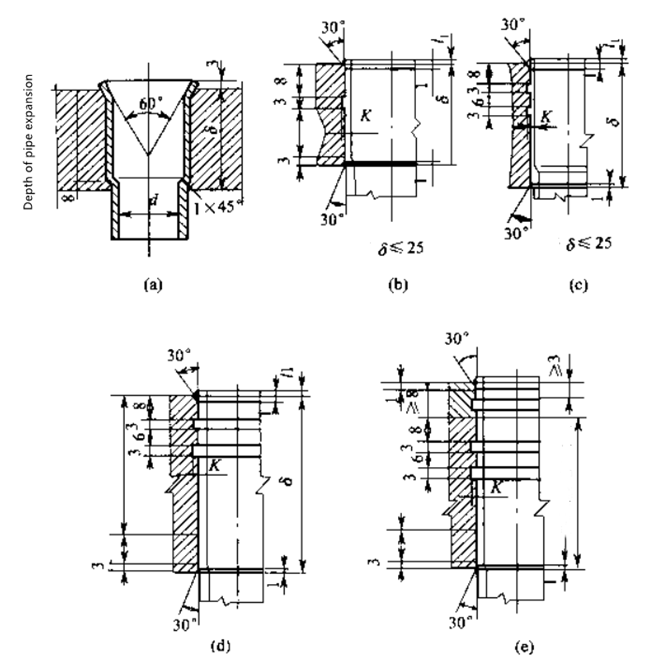

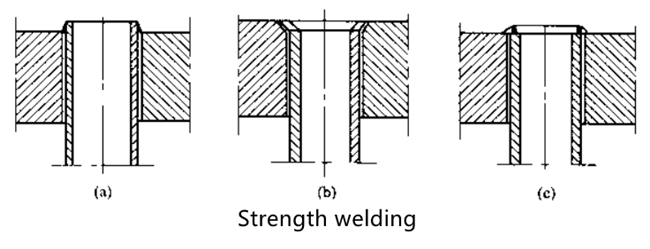

The connection form of heat exchange tube and tube plate mainly includes expansion, welding, expansion welding, etc. The strength expansion joint refers to the expansion of the sealing performance and tensile strength of the connection between the heat exchange tube and the tubesheet. It relies on the plastic deformation of the tube end to withstand the pulling force. The residual stress after the expansion of the tube will gradually weaken when the temperature increase so that the sealing performance and strength of the connection between the tube and the tube sheet will decrease.

Therefore, the strength expansion is suitable for the design pressure is less than or equal to 4MPa, the design temperature is less than or equal to 300℃. The strength expansion should not be used in the case of severe vibration, large temperature difference, or obvious stress corrosion during operation.

When expanding the tube, the hardness of the tube should be lower than that of the tube sheet. The gap between the pipe and the pipe and the smoothness of the pipe affects the quality of the expanding pipe. The rough surface of the pipe hole can produce a large friction force and is not easy to pull off, but it is easy to produce leakage. The surface of the pipe hole is strictly prohibited to have a longitudinal through the groove. The smooth surface of the tube hole is not easy to leak, but easy to pull off. Generally, the surface roughness is required to be less than or equal to 12.5μm. There are two kinds of pipe holes: holes and annular grooving, the former as shown in figure (a) below, and the latter as shown in Figure (b) and (c) below.

After grooving, the steel tubes are squeezed into the grooves when expanding, which can improve the pull-off resistance and enhance the sealing performance. The number of annular slots in the tube hole depends on the thickness of the tube plate. Generally speaking, a slot is opened when the thickness is less than 25mm, and two slots are opened when the thickness is greater than 25mm. When the tube plate is thick or to avoid gap corrosion, the structure shown in the following figure (d) can be used, the composite tube plate and heat exchange tube can also be expanded, when the cladding is greater than or equal to 8mm, should be in the groove on the tube hole, the structure is shown in the following figure (e).

Strength welding refers to ensure the sealing performance and tensile strength of the heat exchange tube and tubesheet connection, is the most widely used tubesheet connection types. Strength welding manufacturing is simple, the tensile ability is strong, such as welding part failure, can be secondary repair welding, more convenient heat exchange tube. The use of strength welding is not limited by pressure and temperature, but it is not suitable for the occasion of large vibration or gap corrosion. The general form of strength welding is shown in figure (a) below. In order to avoid liquid accumulation around the pipe end, the structure as shown in figure (b) below is often used. The structure as shown in figure (c) below is generally used in the situation where the tubesheet is stainless steel.

The sealing performance of the joint between tube and tube plate is required to be high, or there is clearance corrosion, withstand severe vibration and other occasions, single expansion or welding can not meet the requirements, the combination of the two can provide enough strength and good sealing performance. The combination of expansion and welding can be divided into two kinds according to the expansion and welding sequence: expansion and welding after expansion. The general expansion method will inevitably have oil stains in the joint gap, which will be welded after expansion. These oil stains and the air in the gap will reduce the weld quality.

Weld before expansion, will cause damage to the weld. At present, there is no uniform provision for the choice of the two orders. In the actual engineering, such as expansion after welding, before welding should be clean oil; If the first welding after expansion, should be a limit to the expansion position of the tube end, generally to control from the surface of the tube plate 15mm above the scope of expansion. The first expansion and then welding generally adopts the form of strength expansion and seal welding. The strength expansion ensures the sealing performance of the tube and tubesheet, providing enough tensile strength, and the seal welding further ensures the sealing performance of the tube and tubesheet. The structure is shown in the figure (a). Strength welding ensures the sealing performance of the tube and tubesheet, providing sufficient tensile strength, and sticking expansion eliminate the gap between the tube and the tube hole to ensure the sealing performance. The structure is shown in figure (b).

In essence, explosive expansion is also a kind of strength expansion, the latter usually adopts roller expansion, the former uses the explosive in a very short period of time to produce high-pressure gas shock wave to make the pipe firmly attached to the tube hole. High explosive expansion and connection efficiency, no need of lubricating oil, easy to weld after expansion, large tensile strength, small axial elongation and deformation.

Explosive expansion is suitable for thin wall tubes, small diameter tubes and large thickness tube sheet expansion, heat exchange tube end leakage, mechanical expansion is difficult to repair the occasion.

U tube heat exchanger is characterized by its simple structure, good tightness, convenient maintenance and cleaning, low cost, good thermal compensation performance and strong pressure bearing capacity.

The U-tube heat exchanger has the largest heat exchange area under the same diameter. The main structure of U-shaped tube heat exchanger includes tube box, cylinder, head, heat exchange tube, nozzles, baffle, anti-shock plate and guide tube, anti-short circuit structure, support and other accessories of the shell and tube side, is the most commonly used in shell and tube heat exchanger.

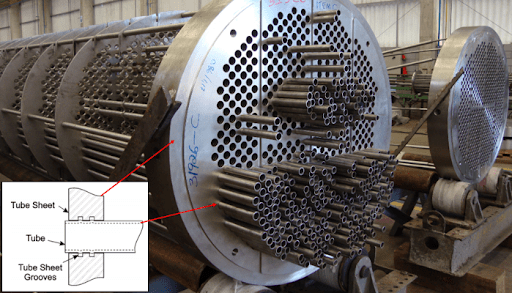

Tube sheet is one of the most important parts of shell – tube heat exchanger. The tube plate is the barrier between the shell side and the pipe side. When the heat exchange medium has no corrosion or slight corrosion, it is generally made of low carbon steel, low alloy steel or stainless steel. The connection form of tube-sheet and shell is divided into non-detachable and detachable types. The former is the connection between tube-sheet and shell in the fixed tube-sheet heat exchanger. The latter, such as U-shaped tube type, floating head type and stuffing box type and sliding tube plate type heat exchanger tube plate and shell connection. For removable connections, the tube plate itself is usually not in direct contact with the shell, but the flange is connected to the shell indirectly or is clamped by two flanges on the shell and the tube box.

Most of the shell tube heat exchangers with larger shell diameters adopt tube and box structures. The tube box is located at both ends of the heat exchanger, which evenly distributes the fluid from the pipe to the heat exchanger tubes and gathers the fluid in the tubes together to send out the heat exchanger. In a multi-pipe shell, the casing can also change the flow direction. The structure of the tube box is mainly determined by whether the heat exchanger needs to be cleaned or whether the tube bundle needs to be divided.

Shell and U-tube heat exchanger has become the most commonly used structure type of heat exchanger in the field of petrochemical industry due to many advantages, but it also has some disadvantages such as pipe cleaning is more difficult, the utilization rate of tube plate is low due to the limitation of curvature radius of bend pipe; The distance between the innermost tubes of the tube bundle is large, the shell process is easy to short circuit, and the scrap rate is high. It is suitable for large temperature difference between pipe and shell wall or shell side where medium is easy to scale and needs cleaning, and is not suitable for using floating and fixed tube plate type occasions, especially suitable for clean and not easy to scale under high temperature, high pressure, corrosive medium.

A tube sheet is usually made from a round flat piece of plate,sheet with holes drilled to accept the tubes or pipes in a accurate location and pattern relative to one another.The tube sheets are used to support and isolate tubes in heat exchangers and boilers or to support filter elements. Tubes are attached to the tube sheet by hydraulic pressure or by roller expansion. A tube sheet may be covered in a cladding material which serves as a corrosion barrier and insulator. Low carbon steel tube sheets can include a layer of a higher alloy metal bonded to the surface to provide more effective corrosion resistance without the expense of using the solid alloy,which means it can save a lot of cost.

Tube sheet is one of the most important parts of shell – tube heat exchanger. The tube plate is the barrier between the shell side and the pipe side. When the heat exchange medium has no corrosion or slight corrosion, it is generally made of low carbon steel, low alloy steel or stainless steel. The connection form of tube-sheet and shell is divided into non-detachable and detachable types. The former is the connection between tube-sheet and shell in the fixed tube-sheet heat exchanger. The latter, such as U-shaped tube type, floating head type and stuffing box type and sliding tube plate type heat exchanger tube plate and shell connection. For removable connections, the tube plate itself is usually not in direct contact with the shell, but the flange is connected to the shell indirectly or is clamped by two flanges on the shell and the tube box.

Perhaps the best known use of tube sheets are as supporting elements in heat exchangers and boilers. These devices consist of a dense arrangement of thin walled tubes situated inside an enclosed, tubular shell. Tubes are supported on either end by sheets which are drilled in a predetermined pattern to allow the tube ends to pass through the sheet. The ends of the tubes which penetrate the tube sheet are expanded to lock them in place and form a seal. The tube hole pattern or “pitch” varies the distance from one tube to the other and angle of the tubes relative to each other and to the direction of flow. This allows the manipulation of fluid velocities and pressure drop, and provides the maximum amount of turbulence and tube surface contact for effective Heat Transfer.

In cases where it is critical to avoid fluid intermixing, a double tube sheet can be provided. The design of tube sheets is a fairly precise and complex process; the exact number of tubes needs to be established and a pattern of holes calculated to spreads them evenly over the tube sheet surface. Large exchangers may have several thousand tubes running through them arranged into precisely calculated groups or bundles. Sheet design and production is largely automated these days with computer software (like CAD) performing the calculations and the tube sheet drilling done on computer numerical control (CNC) machines. In this design, the outer tube sheet is outside the shell circuit, virtually eliminating the chance of fluid intermixing. The inner tube sheet is vented to atmosphere so any fluid leak is easily detected. Duwa Piping factory drilling department has professional drilling equipment and working team, we can provide the best quality tube sheet for you .

| Abbr. | Corresponding | Application |

|---|---|---|

| A179 | ASTM A179 / A179M | Standard Specification for Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes |

| A213 | ASTM A213/A213M | Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes |

| A214 | ASTM A214 / A214M | Specification for Electric-Resistance-Welded Carbon Steel Heat-Exchanger and Condenser Tubes |

| A249 | ASTM A249 / A249M | Specification for Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubes |

| A498 | ASTM A498 / A498M | Specification for Seamless and Welded Carbon, Ferritic, and Austenitic Alloy Steel Heat-Exchanger Tubes with Integral Fins |

| A851 | ASTM A851 / ASME SA851 | Specification for High-Frequency Induction Welded, Unannealed, Austenitic Steel Condenser Tubes |

Steel pipe delivery status(condition): cold / hard (BK), cold / soft (BKW), after cold stress relief annealing (BKS), annealing (GBK), normalized (NBK).

| Term | Symbol | Explanation |

|---|---|---|

| Cold-finished/hard (cold-finished as-drawn) | BK | No heat treatment after the last cold-forming process. The tubes therefore have only low deformability. |

| Cold-finished/soft (lightly cold-worked) | BKW | After the last heat treatment there is a light finishing pass (cold drawing) With proper subsequent processing, the tube can be cold-formed (e.g. bent, expanded) within certain limits. |

| Annealed | GBK | After the final cold-forming process the tubes are annealed in a controlled atmosphere or under vacuum. |

| Normalized | NBK | The tubes are annealed above the upper transformation point in a controlled atmosphere or under vacuum. |

The general cold strip mills, volume should go through continuous annealing (CAPL unit) to eliminate cold hardening and rolling stress, or batch annealing reach the mechanical properties of the corresponding standard specifies. Cold rolled steel surface quality, appearance, dimensional accuracy better than hot-rolled plate, and right-rolled thin product thickness is about 0.18mm, so the majority of users favor.

Cold rolled steel coil substrate products deep processing of high value-added products. Such as electro-galvanized, hot dip galvanized, electro-galvanized fingerprint resistant, painted steel roll damping composite steel, PVC laminating steel plates, etc., so that the excellent quality of these products has a beautiful, high resistance to corrosion, has been widely used.

Cold rolled steel coil finishing after annealing, cut the head, tail, trimming, flattening, smooth, heavy volume, or longitudinal clipboard. Cold-rolled products are widely used in automobile manufacturing, household electrical appliances, instruments, switches, buildings, office furniture and other industries. Steel plate strapping package weight of 3 to 5 tons. Flat sub-volume typically 3 to 10 tons / volume. Coil diameter 6m.

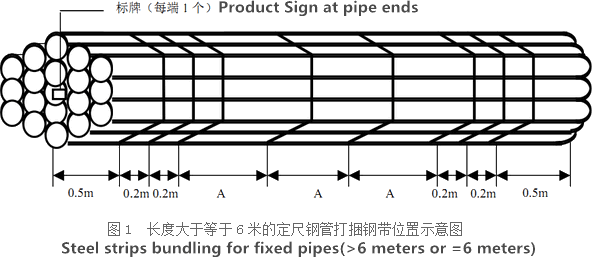

Bare packing/bundle packing/crate packing/wooden protection at the both sides of tubes and suitably protected for sea-worthly delivery or as requested.

There are probably hundreds of different methods for packing a pipe, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.

Our packing can meet any needs of the customers.

Our team of experienced sales specialists proudly partners with gas and chemical processors, power generation plants, oil refineries, and related industries to offer piping components and value-added services.

Alloy steels are made by combining carbon steel with one or several alloying elements, such as manganese, silicon, nickel, titanium, copper, chromium and aluminum. These metals are added to produce specific properties that are not found in regular carbon steel. The elements are added in varying proportions (or combinations) making the material take on different aspects such as increased hardness, increased corrosion resistance, increased strength, improved formability (ductility); the weldability can also change.

Commonly used alloying elements and their effects are listed in the table given below.

| Alloying Elements | Effect on the Properties |

|---|---|

| Chromium | Increases Resistance to corrosion and oxidation. Increases hardenability and wear resistance. Increases high temperature strength. |

| Nickel | Increases hardenability. Improves toughness. Increases impact strength at low temperatures. |

| Molybdenum | Increases hardenability, high temperature hardness, and wear resistance. Enhances the effects of other alloying elements. Eliminate temper brittleness in steels. Increases high temperature strength. |

| Manganese | Increases hardenability. Combines with sulfur to reduce its adverse effects. |

| Vanadium | Increases hardenability, high temperature hardness, and wear resistance. Improves fatigue resistance. |

| Titanium | Strongest carbide former. Added to stainless steel to prevent precipitation of chromium carbide. |

| Silicon | Removes oxygen in steel making. Improves toughness. Increases hardness ability |

| Boron | Increases hardenability. Produces fine grain size. |

| Aluminum | Forms nitride in nitriding steels. Produces fine grain size in casting. Removes oxygen in steel melting. |

| Cobalt | Increases heat and wear resistance. |

| Tungsten | Increases hardness at elevated temperatures. Refines grain size. |

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.