Bearing Pipes

Pipes designed for bearing loads, offering high strength and durability.

The Seamless steel pipe for ship building usage are mainly used for Level 1& Level 2 pressure pipe in piping system, boiler and super-heated unit of shipbuilding.

Shipbuilding involves the assembly of various structural elements, and tubes play a crucial role in this process.

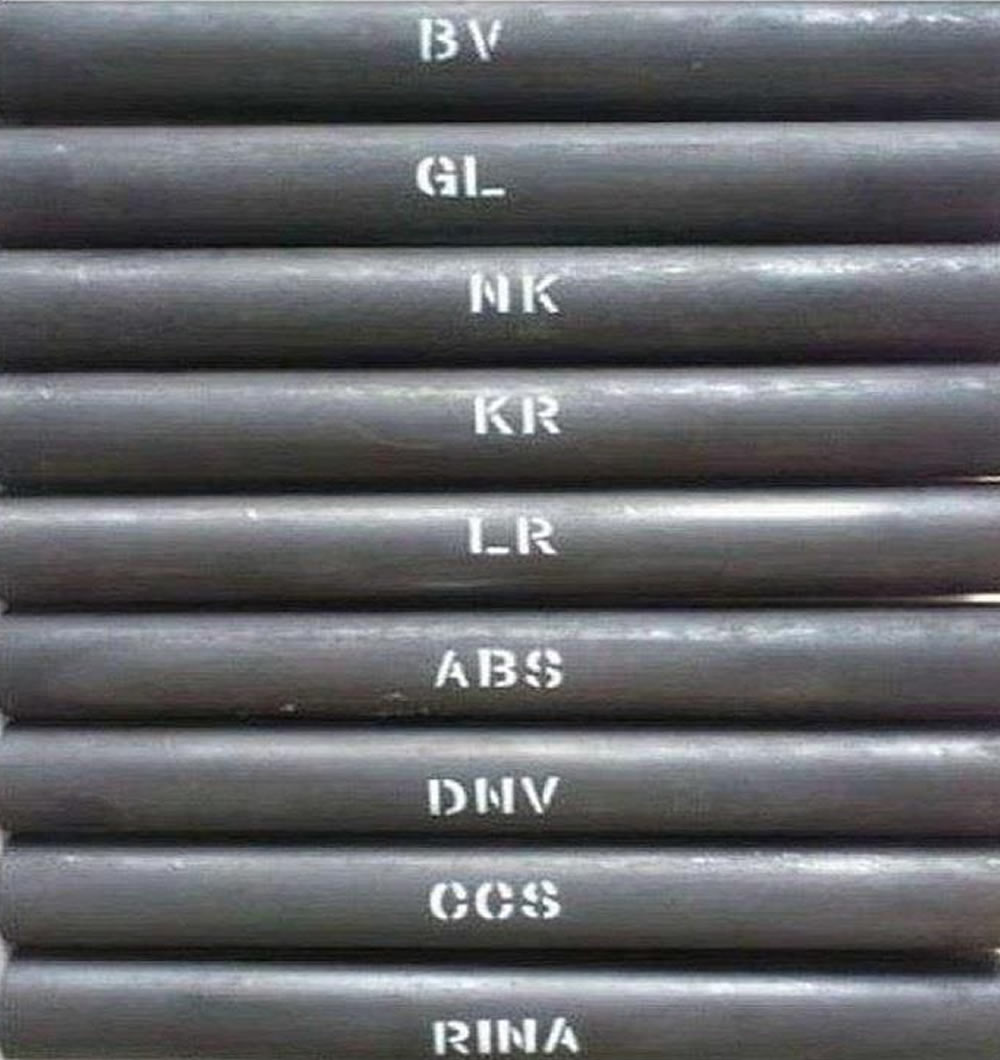

We predominantly produce steel pipes in the following grades and specifications:

Additionally, upon discussion and agreement, we are capable of supplying steel pipes of other grades and specifications to cater to your unique requirements.

Seamless tubes are approved by classification societies such as CCS, LR, GL, DNV, and ABS .

The following standards are adhered to in the production of tubes for marine boilers, superheaters, and piping systems classified into Class I, II, and III, as well as for the manufacturing of tubes used in liquefied gas transportation and bulk chemical carriers:

Compliance with these stringent standards ensures the quality and safety of marine equipment, which is critical for the operation of vessels in the global maritime industry.

Shipbuilding tubes find applications in various systems and components, including:

There are two types of seamless for marine use: power piping and marine system piping.

Seamless steel tubes for ship-building refer to the ship building steel pipes which are designed and manufactured for boilers,super heaters and pressure systems of ship. The ship building steel pipes can be expansively used in various kinds of ships such as CCS,DNV,LR,GL,ABS,BV,RINA,NK as well as China national standards.

Two systems of ship and marine engineering demand roughly in three types of steel pipe:

Different ship and marine engineering, both conventional systems have a dedicated system.

Ship service life of 20 years. Many of the conventional system, bilge water, ballast, dewater sewage, air, measurement, injection, domestic water, fire, cargo oil stripping, breathable, inert gas, heating, washing, foam extinguishing sprinkler, vapor, liquid level telemetry, valve remote control systems, special ships also include a dedicated system for the transportation of liquefied petroleum gas (LPG), liquefied natural gas (LNG). Marine engineering service life of up to 30 years, or even longer. Marine engineering in addition to the conventional system, special drilling equipment systems, crude oil / LPG / LNG processing workflow system, special mooring system, flare system, and so on. It has been statistics, ship pipe annual consumption of 450 million tons, about 440,000, its standards are GB, YB, CB, 70% of the steel pipe connection. Only a 30-ton very large crude oil pipes for the amount of up to tens of kilometers, only steel pipe usage (including), there are about 1,500 tons, of course, the amount of 40,000 tons relative to the hull structure or limited. In addition, taking into account the same ship, to the construction of ships, as well as many other ships, so the cumulative dosage is also a lot of. And a 300,000 tons-class number of large FPSO pipe over 30,000, more than 90 km in length, which is the same tonnage level 2 to 3 times. Therefore, the shipbuilding industry has become a big user of steel pipe market.

Pipe for Ship-building (GB5312-1999): Carbon Steel and Carbon-manganese Steel Seamless Pipes for Ship-building is mainly is used for Level 1& Level 2 pressure pipe. The standard materials are Grade 360,410,460 etc.

Steel tube marine engineering applications, in addition to the above conventional system with a dedicated system, many constructed a large number of steel pipes, such as jacket, underwater steel piles, Casing, mooring bracket, helicopter platform, torch tower. Type of steel pipe, material specifications, with the same diameter, reducers, different wall thickness, as well as a large number of Y, K, T-managed nodes. Such as jacket, steel piles, wellhead impermeable sleeve, mostly large diameter steel pipe sizes, are generally made of rolled steel. Their material for E36-Z35, D36-Z35, E36, D36. Such steel pipe standards have not with YB, CB, and mainly is GB712-2000. The production of steel pipe structure steel pipe manufacturing practice SY/T10002-2000 developed by China’s Petroleum Industry Standards and Technology Commission (CPSC). Since China does not have the specialized enterprises, are usually the purchase of steel plate from construction units, self-molding process.

| Pipe Range | I | Ⅱ | Ⅲ | |||

|---|---|---|---|---|---|---|

| Designed Pressure(Mpa) | Designed Temperature (℃) | Designed Pressure (Mpa) | Designed Temperature (℃) | Designed Pressure (Mpa) | Designed Temperature (℃) | |

| > | ≤ | |||||

| Steam and Hot Oil | 1.6 | 300 | 0.7-1.6 | 170-300 | 0.7 | 170 |

| Fuel Oil | 1.6 | 150 | 0.7-1.6 | 60-150 | 0.7 | 60 |

| Other Media | 4 | 300 | 1.6-7.0 | 200-300 | 1.6 | 200 |

When the designed pressure and temperature reach the ones in the above Class I, this steel pipe belongs to Class I pipe. If it meets the pressure and temperature of Class II, it is defined to be the Class II pipe.

Other media refer to air, water, lubricating oil and hydraulic oil.

Class III seamless steel tubes can be manufactured in accordance with the national standards approved by the ship inspection department.

1) As for the seamless steel pipe for boiler and super heater purpose, the working temperature of wall thickness does not exceed 450℃.

2) The dimension of marine seamless steel pipe should firstly select the general steel pipe size in the first group of GB/T7395-1998 table one. The outside diameter of steel tube should choose the standard outside diameter size in the first series of GB/T7395-1998. We can also produce pipes with other specifications not appear in the GB/T7395-1998 table one.

Special purpose steel special steel pipe used in the specific working environment and the working medium. Undersea pipeline is typical specialty steel pipe, the demand for larger, high strength, small tolerances, good corrosion resistance. Currently, the pipeline production is only in its infancy, because the welding materials, corrosion resistance or less Specifications (diameter and wall thickness), expensive, etc. China’s offshore crude oil need insulation transport. The past, using the double pipe insulation structure, safe and reliable. But as a protective pipe steel pipe is very economical, and offshore pipe laying ago, have to carry out internal and external pipe welding, greatly reducing the efficiency of the pipe laying, to cause installation costs increase exponentially. Into the 21st century, it has launched a concrete counterweight steel pipe.

Its structure is (from inside to outside):

anti-corrosion layer of steel, epoxy powder (FBE), polyurethane insulation, polyethylene (PE) jacket tube, reinforced concrete counterweight layer (the internal configuration of the steel mesh). This type of special steel, China has imported from abroad, such as the Bohai Penglai 19-3 oil field, a project using Malaysian BREDEROPRICE company products. China after research and testing, and in 2002 built in Tanggu, China’s first concrete with heavy steel pipe production line, has thousands of kilometers of pipelines for offshore oilfield products. It is reported that, using this steel per kilometer subsea pipeline to reduce the cost of 50 million to 100 million, and greatly reduce the cost of offshore oilfield development, so that a number of marginal oil fields to be cost-effective to develop.

Specifications of Marine Seamless Steel Pipe Table 1 Grade of Seamless Steel Pipe (Pressure Tubing)

| Society | Standard or usage | Steel grade | C | Si | Mn | P | S | Cr | Ni | Cu | Al | Mo | V | P+S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GLR | Non alloly | GL-R 410 | ≤0.21 | ≤0.35 | ≤1.4 | ≤0.025 | ≤0.02 | - | - | - | ≥0.020 | - | - | - |

| GB 18248 | 37Mn | 0.34~0.40 | 0.1~0.30 | 1.35~1.65 | ≤0.03 | ≤0.03 | ≤0.3 | ≤0.3 | ≤0.2 | - | - | - | ≤0.055 | |

| EN 10297 | 34CrMo4 | 0.3~0.37 | ≤0.4 | 0.6~0.90 | ≤0.035 | ≤0.035 | 0.9~1.20 | - | - | - | 0.15~0.30 | - | - | |

| DNV | for pressure ASTM A53/A53M | A53B | ≤0.3 | - | ≤1.2 | ≤0.05 | ≤0.045 | ≤0.4 | ≤0.4 | ≤0.4 | - | ≤ | ≤ | - |

| 0.15 | 0.08 | |||||||||||||

| ABS | for pressure | Grade 3 | ≤0.3 | - | ≤1.2 | ≤0.05 | ≤0.045 | ≤0.4 | ≤0.4 | ≤0.4 | - | ≤0.15 | ≤0.08 | - |

| BV | for pressure | 410HB | ≤0.21 | ≤0.35 | 0.4~1.20 | ≤0.04 | ≤0.04 | - | - | - | - | - | - | - |

| LR | for pressure | 410 | ≤0.21 | ≤0.35 | 0.4~1.20 | ≤0.045 | ≤0.045 | ≤0.25 | ≤0.3 | ≤0.3 | - | ≤ | - | - |

| KR | for pressure | RST138 | ≤0.25 | ≤0.35 | 0.3~0.90 | ≤0.04 | ≤0.04 | - | - | - | - | - | - | - |

| RST142 | ≤0.3 | 0.3~1.00 | ≤0.04 | ≤0.04 | - | - | - | - | - | - | - | |||

| RST238 | ≤0.25 | 0.1~0.35 | 0.3~1.10 | ≤0.035 | ≤0.035 | - | - | - | - | - | - | - | ||

| RST242 | ≤0.3 | 0.3~1.40 | - | - | - | - | - | - | - | |||||

| RST249 | ≤0.33 | 0.3~1.50 | - | - | - | - | - | - | - | |||||

| RST338 | ≤0.25 | 0.3~0.90 | - | - | - | - | - | - | - | |||||

| RST342 | ≤0.3 | 0.3~1.00 | - | - | - | - | - | - | - | |||||

| NK | for pressure | grade 1 No3/ KSTPG 42 | ≤0.3 | ≤0.35 | 0.3~1.00 | ≤0.04 | ≤0.04 | - | - | - | - | - | - | - |

| CCS | for pressure | 360 | ≤0.17 | ≤0.35 | 0.4~0.80 | ≤0.04 | ≤0.04 | ≤0.25 | ≤0.3 | ≤0.3 | ≤0.10 | |||

| 410 | ≤0.21 | ≤0.35 | 0.4~1.20 | ≤0.04 | ≤0.04 | ≤0.25 | ≤0.3 | ≤0.3 | ≤0.10 | |||||

| 460 | ≤0.22 | ≤0.35 | 0.8~1.40 | ≤0.04 | ≤0.04 | ≤0.25 | ≤0.3 | ≤0.3 | ≤0.10 | |||||

| 490 | ≤0.23 | ≤0.35 | 0.8~1.50 | ≤0.04 | ≤0.04 | ≤0.25 | ≤0.3 | ≤0.3 | ≤0.1 | |||||

Note:

residual elements:Cr≤0.25%, Mo≤0.10%, Ni≤0.30%, Cu≤0.30%aggregate≤0.70%

With years of expertise, we provide a diverse array of steel tube processing options. From sawing and machining tube blanks to intricate bending and upsetting operations, we actively assist you throughout your projects.

Our capabilities extend to eccentricity reduction and concentricity enhancement through turning and grinding. We excel in creating complex geometries using processes like rotary swaging and axial forming. Additionally, we offer property modifications via partial heat treatment, ensuring tailored solutions for your specific needs.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.