U bend tubes

U Bend tube heat exchangers designed for high temperature applications, especially steam condensing or hot oil systems.

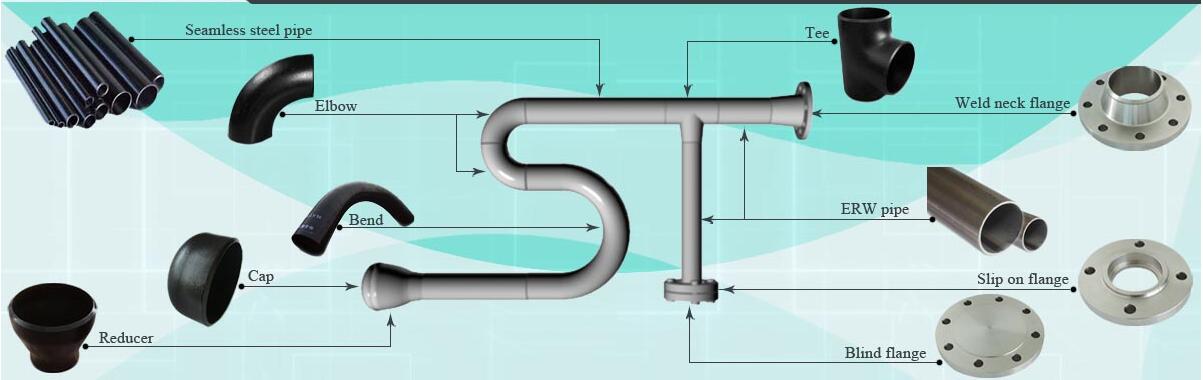

A fitting is a weldable pipe fitting that allows for change of direction of flow, to branch off, reduce pipe size or attach auxiliary equipment.

Pipe fitting is the occupation of installing or repairing piping or tubing systems that convey liquid, gas, and occasionally solid materials.

Pipe fitting is work that involves the installation or repair of pipes or tubes.

Butt weld pipe fittings allow for changing the direction of flow, reducing pipe sizes and attaching auxiliary equipment.

A common example using welded pipe fitting is a pipe reduced by concentric reducer, welded to a weld neck flange and connected to an equipment.

Pipe flanges are basically plates or rings used to connect pipes, valves and other piping equipment to form a piping system.

A flange standard lays down the dimensions, surface finish, facing type, marking, material and technical specifications for flanges.

Expansion joints are installed in a piping system to absorb vibration and shock.

Expansion joint comes in two forms either restrained or unrestrained styles and although the bellows membrane incorporated in both styles look similar it is of great importance to recognize that they are used for entirely different applications.

Fittings are components that are used to connect, join, or adapt different parts of a system, such as pipes, tubes, or hoses. They serve multiple purposes, including:

Fittings are used to connect sections of pipes, tubes, or hoses, ensuring a secure and leak-free joint.

Flanged

Butt welded

They allow for changes in the direction of fluid or gas flow within a system, such as elbows or bends.

Fittings can adapt pipes or tubes of different sizes, ensuring compatibility.

They enable branching or splitting of fluid or gas flow into multiple directions, like tees or crosses.

Some fittings incorporate valves or controls to regulate or stop the flow as needed.

Fittings may include pressure-relief valves or regulators to control fluid or gas pressure.

Fittings with inspection ports or couplings facilitate system maintenance and testing.

Fittings allow pipes or hoses to connect to various equipment or appliances.

The choice of fittings depends on the specific requirements of the system, including factors like the type of fluid or gas, pressure, temperature, and the layout of the piping or tubing system. Different industries, such as plumbing, HVAC (Heating, Ventilation, and Air Conditioning), manufacturing, and construction, rely on fittings to ensure the proper functioning of their systems.

They are designed to provide a secure and leak-free connection while withstanding corrosive environments and high temperatures.

Visual Inspection is conducted on fittings to check any surface imperfections. Both fittings body and weld are checked for any visible surface imperfections such as dents, die marks, porosity, undercuts, etc. Acceptance as per applicable standard.

For packing of carbon steel flanges with painting,we would use the bubble wrap to protect the painting.For flanges without painting or oiled with long-term shipment,we would suggest client to use the anti-tarnish paper and plastic bag to prevent the rust.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.