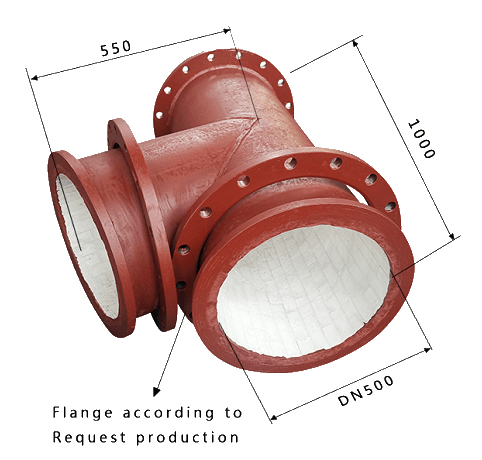

92% Ceramic Lined Coal Pipes

Discover our high-abrasion 92% ceramic lined coal steel pipes, designed for durability and performance in harsh environments.

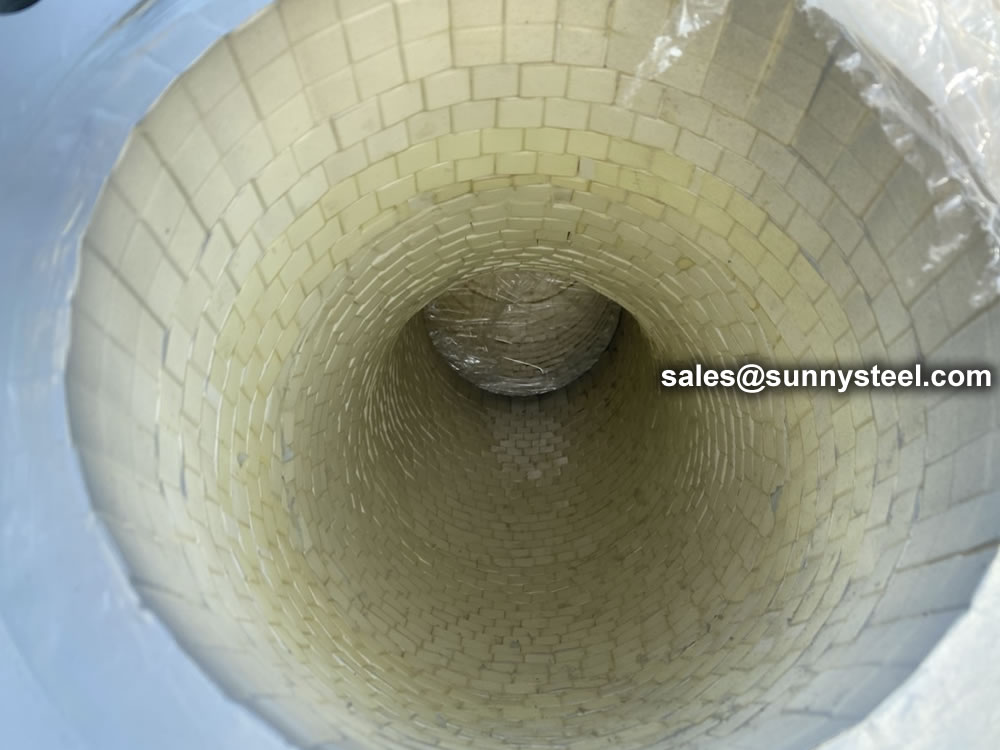

Ceramic tile lined pipes are pipelines that have a ceramic tiles lining layer inside a steel pipe.

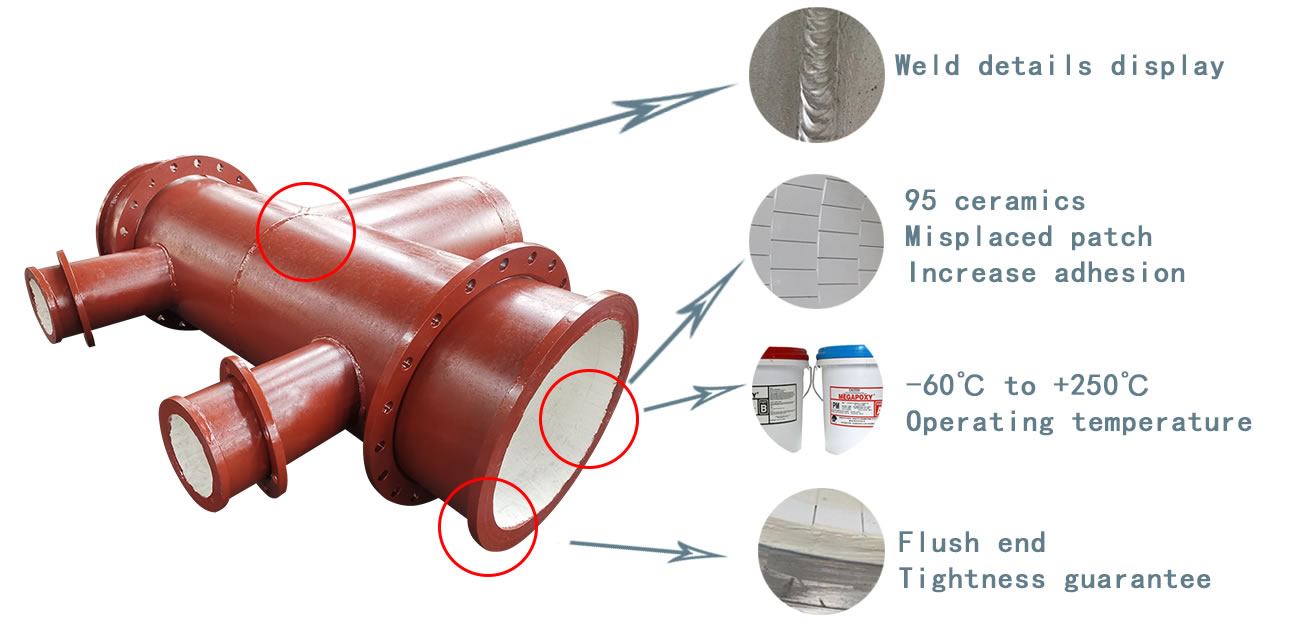

Ceramic Tile Lined Pipe is a type of pipeline that includes a ceramic lining layer that offers exceptional wear and corrosion resistance in high-abrasion environments. The ceramic tile lining is bonded to the inner steel pipe by a high temperature epoxy adhesive, which ensures excellent adhesion and an uninterrupted flow of material through the pipeline.

Ceramic tile lined pipes are widely used in industries such as power generation, mining, cement, steel, and chemical processing, among others. It is particularly well-suited for conveying abrasive slurries such as coal ash, minerals, and ores, as well as corrosive and high-temperature fluids.

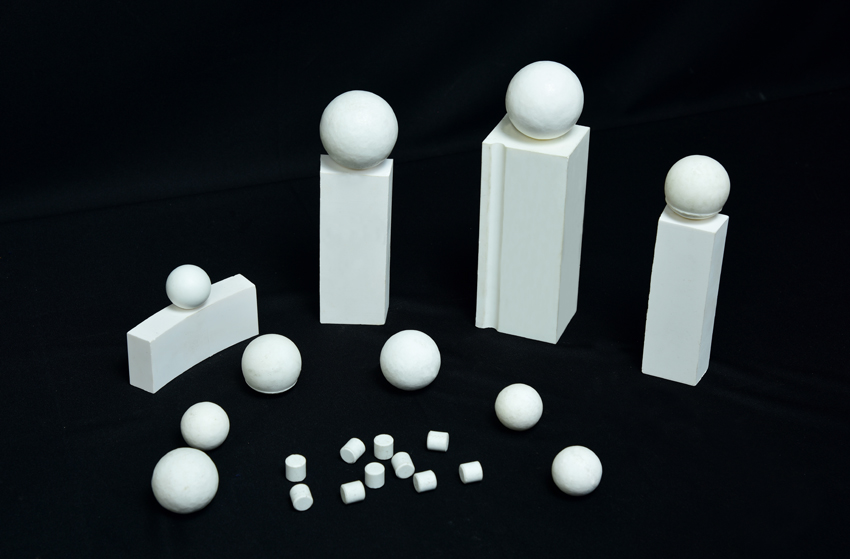

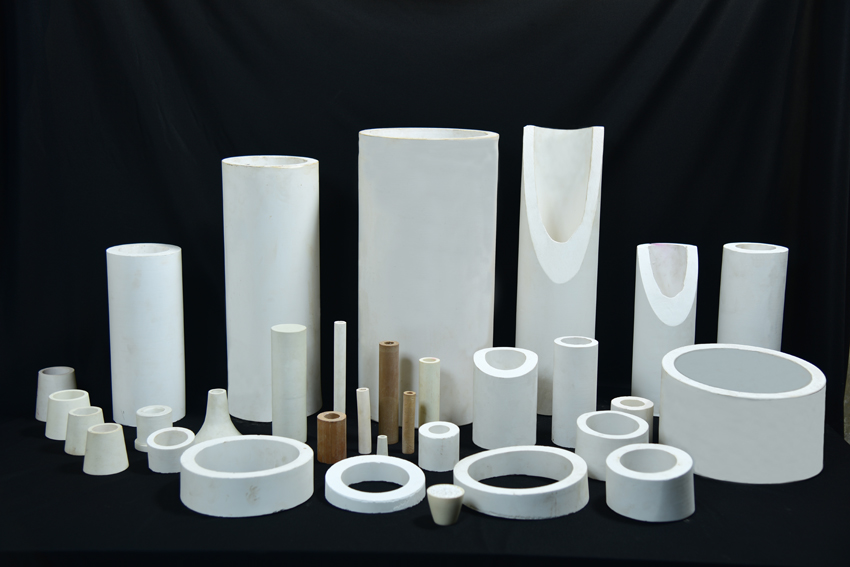

The ceramic tiles used in the lining are usually made from materials such as alumina, zirconia, silicon carbide, or other advanced ceramics, depending on the specific application requirements. The thickness and density of the ceramic tile lining can also be customized based on the specific application demands.

High alumina ceramic refers to a type of ceramic material that contains a high percentage of alumina (aluminum oxide) as its primary component. Alumina is a ceramic oxide with excellent mechanical and thermal properties, making high alumina ceramics widely used in various industrial and engineering applications.

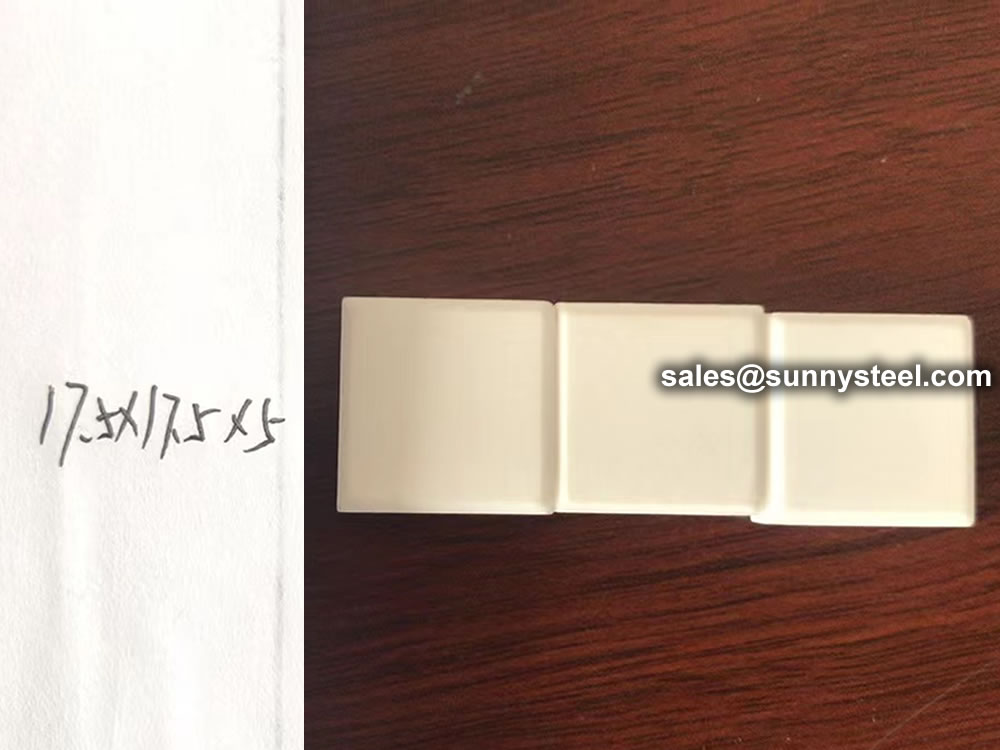

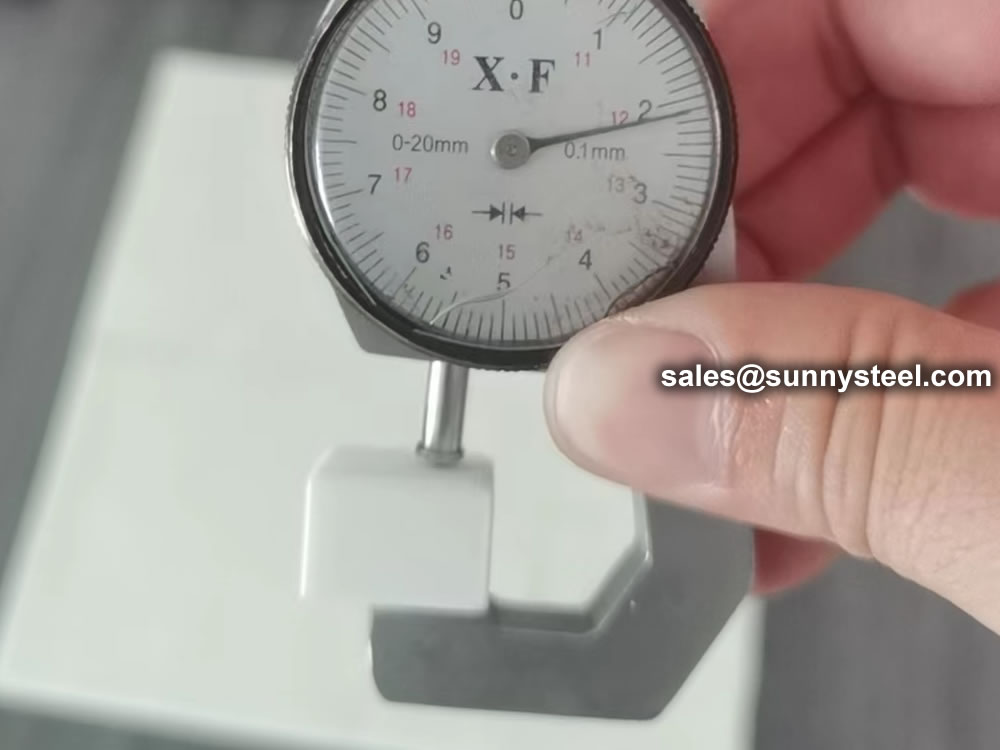

There are many clients who are concerned about the specification of ceramic lined tile sheet, because it is related to whether the ceramic chip purchased can be used.

Main performance indicators: The wear resistance of the ceramic work surface is more than 100 times that of manganese steel, 20 times that of high chromium cast iron, and several times to several dozen times higher than that of wear resistant rubber. Ceramic metal bonding strength up to 300kg/cm2 can be used up to 500°C.

The use of equipment made of wear-resistant ceramics, the service life can be increased by more than five times, and the performance-cost ratio can be increased by more than three times.

Wear resistant ceramic lining is AL203 as the main material, with rare metal oxide as solvent, after more than 1700℃ high temperature roasting to special ceramic, embedded into rubber , polyurethane or mild steel for the purpose of low to moderate impact and highly abrasive sliding application.

The abrasion pipe of thermal power plant is mainly conveying raw coal powder, ash slag, flue gas desulfurization (FGD) limestone powder and slurry, due to the transmission of medium velocity fast, poor operating conditions, resulting in pipelines, especially elbow, variable diameter pipe serious wear and corrosion, not only consumes a lot of metal materials, but also to the thermal power plant security, economic operation has brought hidden dangers. The abrasion mechanism of pipeline is mainly based on erosion wear. Wear-resistant pipe can be divided into two categories: single metal pipe and composite pipe.

The lined ceramic double-flanged limited expansion joint is created by adhering alumina ceramic tiles to the inner wall of the pipe using a high-temperature adhesive.

After heating and curing, it forms a robust anti-wear layer. This type of product has a relatively simple manufacturing process, a short production cycle, and lower costs.

Technical Specifications: SunnySteel offers various models of ceramic lined wear-resistant pipes and can also customize production as per requirements. Ceramic lined wear-resistant pipes are essentially not restricted by pipe size, and they can be produced for diameters ranging from 1 inch to 120 inches or even larger.

It is important to note that expansion joints are not limited to ceramic tiles alone. They are also used in other applications, such as in pipework systems and ducts, where ceramic lined pipe expansion joints are designed to absorb dimensional changes caused by heat-induced expansion.

When installing ceramic tiles, it is crucial to consider the proper placement of expansion joints. Guidelines suggest that grout lines must be wide and proportional to the size of the tiles, and expansion joints in the tiling must also be calculated accordingly.

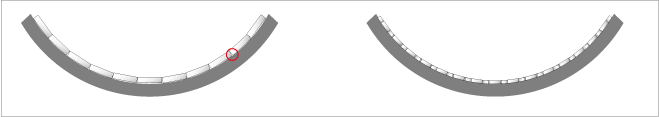

Ceramic tile lined expansion joints are used to accommodate the movement and expansion of ceramic tile surfaces, preventing cracks and damage. They can be installed in various ways, such as creating gaps between tiles or toothed around the tiles in an offset-bond pattern.

Ceramic-Lined Screw Conveyors for Conveying Abrasive Coal

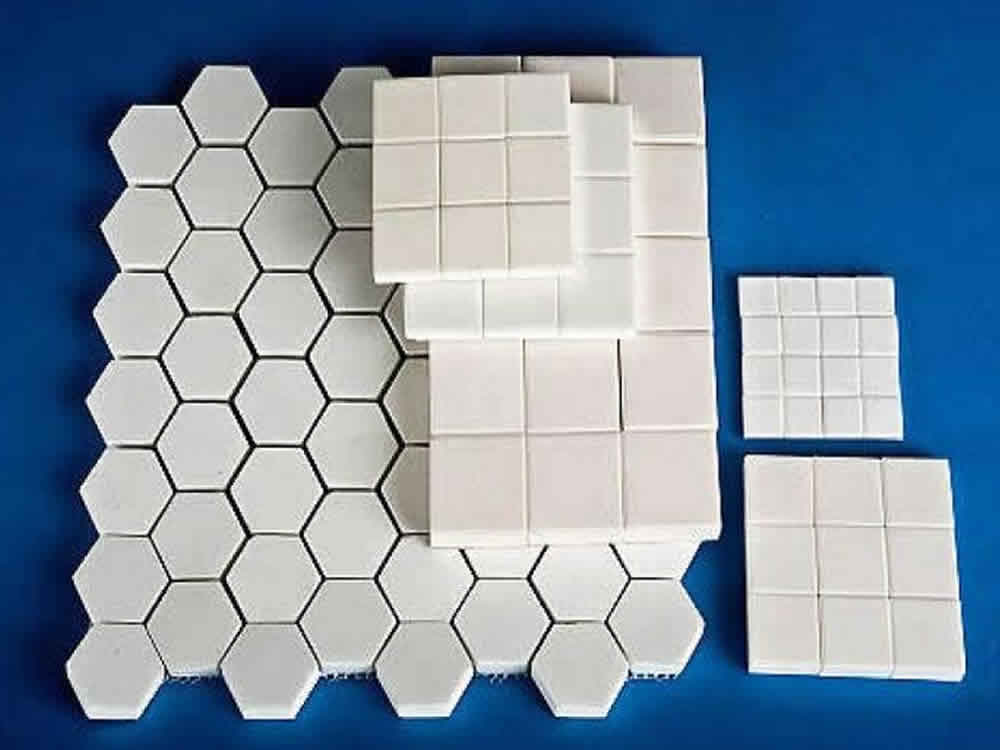

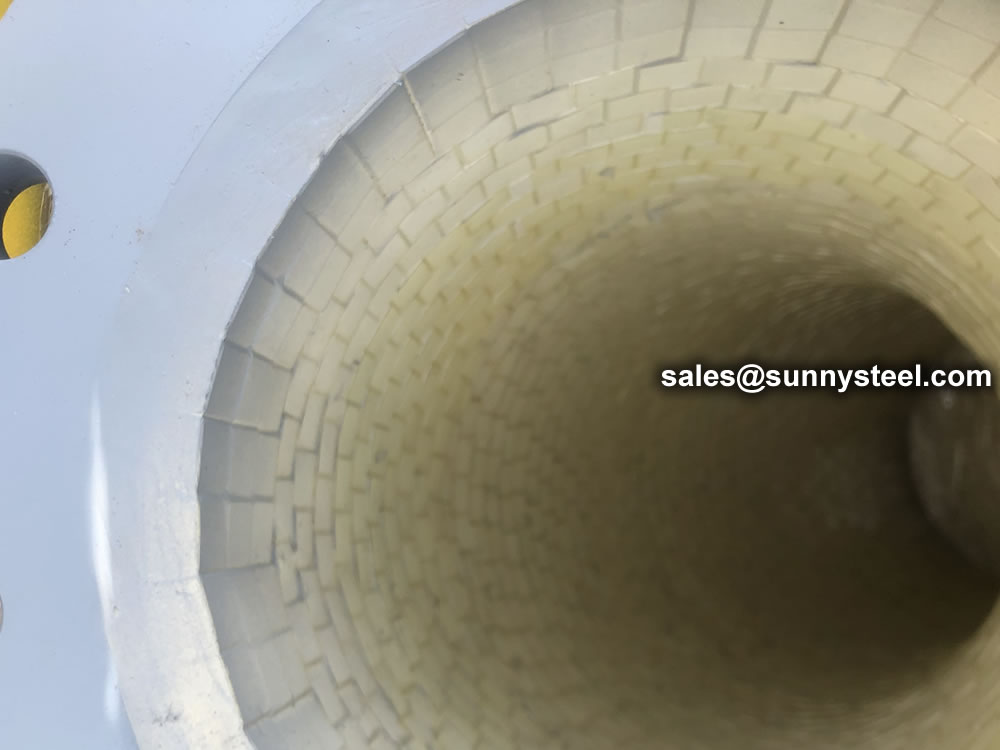

Example of a screw lining with alumina ceramic mosaic size 20x20x4 mm throughout an overall length of nearly 5 m. Bonded by means of a 2-component special adhesive.

After heating and curing, it forms a robust anti-wear layer. This type of product has a relatively simple manufacturing process, a short production cycle, and lower costs.

High alumina ceramics find a wide range of applications in various industries, including:

The specific properties and applications of high alumina ceramics may vary depending on the composition and manufacturing process. They are valued for their combination of hardness, thermal resistance, and chemical inertness, making them essential materials in numerous industrial and technological fields.

Ceramic tile lined pipe using ceramic-metal composite production technology principle, with Al2O3 as raw material.

| Item | Thickness | Material | Special points |

|---|---|---|---|

| Steel | 6mm-10mm | Carbon steel | Seamless forming, high impact |

| Glue | 0.5-1mm | High temperature inorganic glue | No aging when working under high temperature/td> |

| Ceramic | 5mm-12mm | 95% alumina ceramic | High density,super wear |

Special Corundum ceramics made of rare metal oxides as solvents and sintered at high temperature by 1730 ℃ through bonding, welding, mosaic, riveting and socket technology, a variety of wear-resistant ceramic pieces, block brick materials in the pipe wear surface, so as to form a surface with excellent wear resistance, and the matrix is still using the composite pipe of ordinary metal.

According to different needs of the choice of wear-resistant ceramic patches, to meet the special needs of users of technical conditions. Compared with the traditional all-metal high alloy pipe fittings, the working face has higher abrasion resistance, which can make the whole wear-resistant and anticorrosion service life of the pipe increase several times to dozens of times times. Overall weight of the first mate down, reduce the amount of steel, reduce the cost of equipment and maintenance costs, improve economic efficiency.

Alumina is a cost effective and widely used material in the family of engineered ceramics. Alumina ceramics have been developed and optimized for maximum wear resistance and corrosion resistance. A high density, diamond like hardness, fine grain structured and superior mechanical strength are the unique properties that make it the material of choice for a wide range of demanding applications.

Alumina Ceramic has uses similar to cast basalt but it has greater resistance to wear in high velocity applications and impact resistance in extreme dynamic systems.

Sunny Steel provides its customers with the full range of abrasion resistant lined pipe work including straight pipe, bends and elbows, reducers, tees and y-pieces. Sunny Steel offers a comprehensive range of lining materials designed to combat erosion.

Basalt and alumina ceramic are the two generally accepted lining materials. Other linings which complement the basalt and ceramic include Eucor, AZS, silicon nitride bonded silicon carbide, and ceramic filled epoxy coatings.

Ceramic tile lined pipe wear good: wear-resistant ceramic pipe lining ceramic layer for wear-resistant engineering ceramics, its hardness (HRA) ≥84, its wear resistance is high chromium wear-resistant cast iron alloy pipe fittings more than 10 times times. The use of 5mm thick ceramic layer, its actual wear-resistant life will be equivalent to 50mm thick wear-resistant cast steel.

Ceramic patch Composite pipe corrosion resistance: the use of different wear-resistant ceramic materials, for different corrosive medium has excellent anti-corrosion properties, acid, alkali, salt and other strong corrosive medium and brine corrosion characteristics.

Ceramic tile lined pipe high temperature performance: wear-resistant ceramic itself with 1200 degrees Celsius above the high-temperature capacity, through reasonable design and use of different composite methods, wear-resistant ceramic pipe fittings can be in-50 ℃ to 800 ℃ humidity range of long-term operation, especially for high-temperature burners and other equipment lining.

Ceramic tile lined pipe to reduce project cost: wear-resistant ceramic pipe is mainly used for conveying particles of liquid-solid two-phase flow and corrosive media, for the replacement of expensive stainless steel tubes, high chromium cast steel pipe, carbide wear-resistant pipe, can directly reduce the project cost, while prolonging the service life. Products cost-effective, can save maintenance, replacement material costs and time.

Ceramic Patch Composite pipe is our company to draw on the domestic and foreign advanced technology of similar products developed on the basis of a shell for steel, wear-resistant ceramic tube of new composite pipe products, with high wear resistance, long service life and so on.

The use of anti-fall porcelain tube, porcelain pipe inlay, so that the paste more flat, more solid.

The use of strong inorganic adhesive paste, wear-resistant steel bowl welding, porcelain tube and steel combined to form a double reinforcement to ensure that the porcelain tube does not fall off.

The surface of the porcelain tube is smooth, the running resistance is small, the scaling is unfavorable.

Flexible installation, high abrasion resistance, convenient processing and moderate cost.

As a result of the use of paste technology, the main use of high-temperature, high-strength adhesives for pasting ceramic patches, and most of the use of high polymer adhesive temperature is not higher than 200 degrees, and the higher the temperature, adhesive strength is lower, aging speed also increased rapidly.

Therefore, the use of paste ceramic technology, the workpiece temperature is generally not higher than 150 ℃, under this temperature, the general ceramic and metal paste strength can reach 200 kg/cm. For higher than this temperature components, can be used ceramic composite wear-resistant process treatment, so that the use of temperature can reach 500 or more than 700 degrees.

Ceramic tile lined pipes are a type of steel pipe that have been lined internally with ceramic tiles to provide superior resistance to wear, abrasion, and corrosion. The ceramic tiles are typically made from high-grade alumina ceramics, which are known for their hardness, strength, and durability.

Ceramic tile lined pipes are commonly used in applications where the pipes are exposed to harsh environments, such as in mining, power generation, and chemical processing. The ceramic lining provides superior wear resistance, protecting the underlying steel pipe from premature failure due to abrasion or corrosion.

In addition to their excellent wear properties, ceramic tile lined pipes may also provide benefits such as reduced friction, improved flow rates, and lower maintenance costs. They may also be used in applications where hygiene is important, as the ceramic lining is non-toxic and does not react with most chemicals.

Ceramic tile lined pipes may be manufactured in various sizes and shapes, including elbows, tees, and reducers, to meet the specific requirements of each application. The ceramic tiles may be bonded to the steel pipe using specialized adhesives, and may be installed using conventional welding techniques.

While ceramic tile lined pipes can offer significant benefits in terms of wear resistance and longevity, they are typically more expensive than traditional steel pipes due to the cost of the ceramic lining and specialized manufacturing processes.

Ceramic tile lined pipe is our company to absorb similar products at home and abroad on the basis of advanced technology developed a shell for the steel body, within the wear-resistant ceramic tube of the new composite pipe products, with high wear resistance long service life and so on.

The use of anti-off porcelain tube, porcelain tube mosaic, so that paste more flat, more solid with a strong inorganic adhesive paste, wear-resistant steel bowl welding, porcelain and steel body combined to form a double reinforcement to ensure that the porcelain tube does not fall off. The installation of flexible, high wear resistance, processing convenience, the cost is moderate.

Rockwell hardness of high alumina ceramics is up to HRA80-90 which is second only to diamond and far exceeds wear-resistant steel stainless

The wear resistance of high alumina ceramics is 266 times that of manganese steel and 171.5 times that of high chromium cast iron. According to our investigation & follow-up to the clients, the service life of equipment can be prolonged over 10 times under the same working conditions.

High alumina ceramics are inorganic oxides with extremely stable molecular structure and no electrochemical corrosion, thus they can resist erosion of acid, alkali, salt solutions and organic Solvents.

Working temperature of high alumina ceramics can be as high as 1400℃.

High alumina ceramics have the properties of self-lubricity and in adhesion, the roughness is only 1/6 that of steel pipes thus less flow Resistance.

The density of high alumina ceramics is about 3.6g/cm3, which is only half that of steel, thus easy for construction and installation.

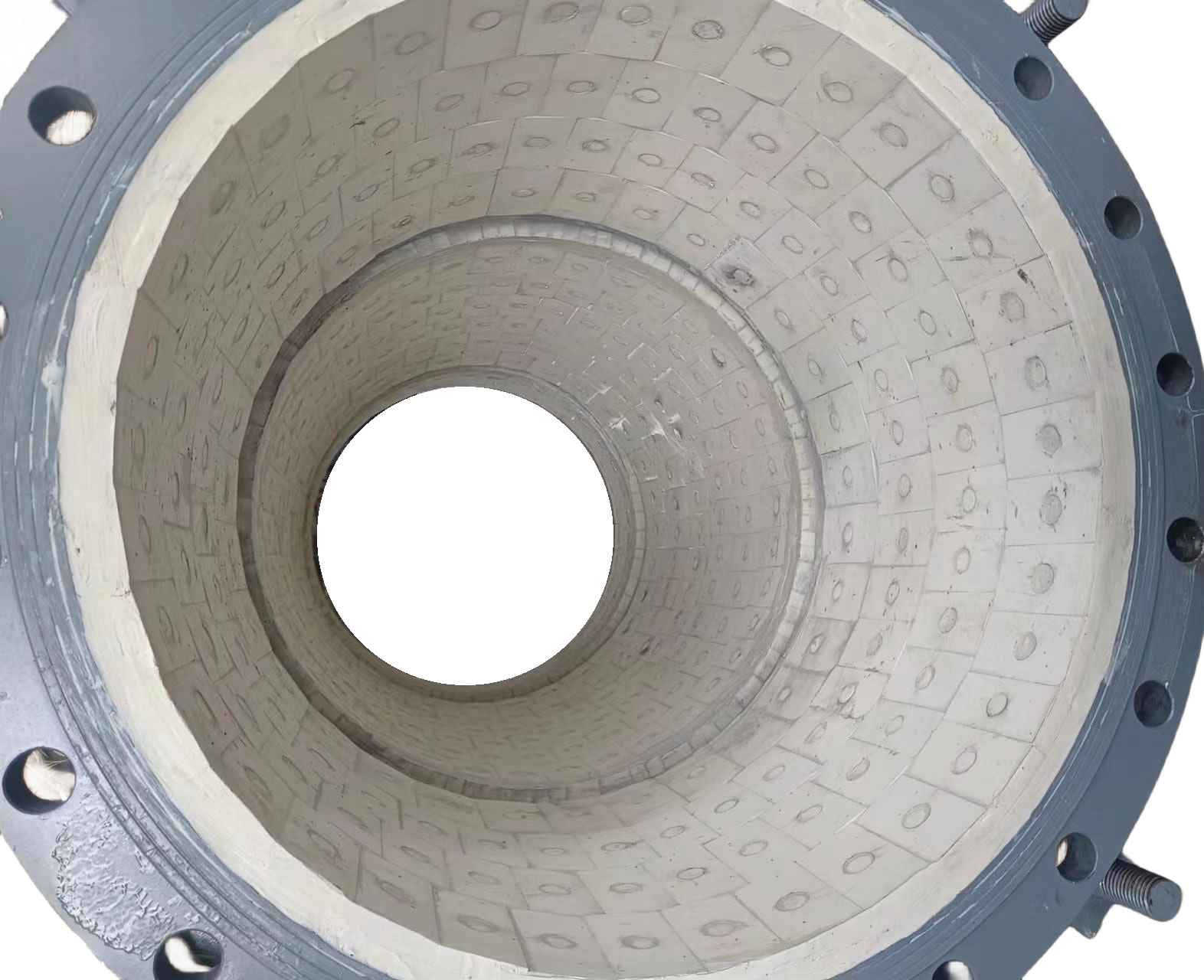

Ceramic tile lined pipe is composed of three layers: outer steel pipe layer, corundum layer, and ceramic glue layer. The inner ceramic layer is white from the surface. The ceramic is generally 95% ceramic, and the temperature is generally below 200°C.

At present, the common ceramic sheets lined with ceramic composite pipes are: ceramic block, dovetail mutual pressure, welding type, mosaic, card slot and so on. It has the characteristics of wear resistance and long service life.

The ceramic tile is pasted on the steel pipe with high temperature wear-resistant glue to play a wear-resistant role, and the pipe is generally white. Generally used for large diameter pipes.

Bends and other profile sections can be clad in whole and this process has changed the traditional practice to fabricate bend and other profile sections by drawing polyline without changing flow pattern of material inside piping, greatly reducing conveyance resistance of material.

The ceramic tiles are pasted to the inner wall of the steel pipe with high temperature wear-resistant glue to play a wear-resistant role.

| No. | Process | Standard | Inspection |

|---|---|---|---|

| 1 | Cleaning the inner surface of the fitting | Clean up all the rubbish and floating ash on the inner surface of construction equipment and pipe fittings. | Checked by the construction supervisor. |

| 2 | Rust removal, oil removal, paint removal | The rust, grease, and paint on the bonding surface must be completely removed without leaving any traces. Use iron sand skin, angle grinder, and soft sand skin to polish to see the metallic luster. After cleaning, wipe the surface with a cloth until there is no trace of dirt. | After the inspection and acceptance by the quality inspector, the construction of the next process can be carried out. |

| 3 | Formulated Adhesives | It must be measured in strict accordance with the prescribed proportion, and how much should be used; it must be stirred evenly, and the overall mixing should not be less than 4 times; if the mixed embedded material is added, the binder must be mixed well before adding the mixture and mixing Not less than 3 times. | Assigned by designated personnel. |

| 4 | Repair of the adhesive surface | If there are potholes on the pasting surface, especially if there are large potholes on the pasting surface of the old equipment, the wear-resistant ceramic sheet must be gradually filled with embedded materials. | After the inspection and acceptance by the quality inspector, the construction of the next process can be carried out. |

| 5 | Paste wear-resistant ceramic tiles | There should be no dust or dirt on the surface of the ceramic tiles. The surface of the repaired inlay material must be leveled. The pasting surface must be wiped again. Scrape the adhesive on the pasting surface for 1-2 times and scrape it flat. Scrape the back of the ceramic sheet for 1 It is necessary to ensure that there is a certain thickness of uniform adhesive available for pasting. | Checked by the person in charge of the construction of the pasted ceramic tiles. |

| 6 | Repair of gaps and corners between ceramic tiles | The gaps exceeding 3 mm must be repaired with wear-resistant and anti-corrosion fillers, the edges and corners must be neat, and the bevels must be trimmed with special ceramic tiles and then filled with fillers. | After the repair, the person in charge of the construction and the quality inspector will conduct a comprehensive quality inspection, and submit it to Party A for acceptance after passing the inspection. |

| 7 | Maintenance time | After construction and repair are completed, it can be put into use after natural maintenance for more than 12 hours after acceptance by Party A. |

There are probably hundreds of different methods for packing a abrasion resistant pipe and Elbows, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.

The use of Ceramic tile lined pipe and fittings is ideal in services that are prone to erosive wear, and where standard pipe and fittings would fail within 24 months or less.

Ceramics with very low friction factor at low impingement angles decreases the abrasion of materials maximally. Its low density makes it easy to carry and install.

These ceramic lined fittings include elbows, bend, reducers and T pipes are bonded with the abrasion resistant alumina or ZTA ceramic tiles into the inner wall of the carbon steel pipes/elbows with strong-high-temperature resistant adhesive, thus form a firm abrasion resistant layer.

This method mainly applied in the pneumatic&hydraulic conveying system and it can be applied in almost all kinks of pipe fittings like coal powder conveying pipes and elbows,dusting,ash, slag removing pipes ,elbows,reducer,T pipe and cross pipe, even laterals, mining slurry conveying pipe fittings and so on. Almost no limitation for the the diameter of the pipe fittings.

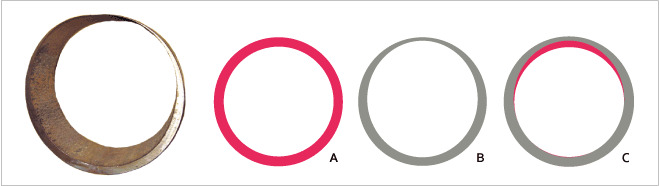

A conventional ceramic tip was arranged with a certain gap between tips in a steel pipe so that the pipe was damaged at the gap before the tip was worn out. The newly developed ceramic tip has a shape with no straight line portion parallel to the transport direction so that the steel pipe is protected until the tip is worn out.

The tailings that are in the pipeline hydraulic transport,which are the phenomena known as the wear abrasion,fatigue,impact.

Have seen that,the use of a tube is 6mm in lenght,the pipe wall thickness was 20mm,and after 8 mounths of using,the bottom is correded till the pipe has 1mm of thickness.

The pipe lined by Dahua has the advantage of the 3mm to 4mm of thickness after 12 mounth of use.

The direction of alignment of ceramics in zig zag,have excellent resistance tc friction of abrasive agents such as sand,gravel,gravel,tailings with solid particles,scale,coal,pulp, tailings from phosphate,salt slag, sludge,ash,..

We are sure that from pure-hearted cooperation we can establish good relationships. Feel free to contact us, we are sure to satisfy you with our professional information, top quality products, best price, and efficient services.

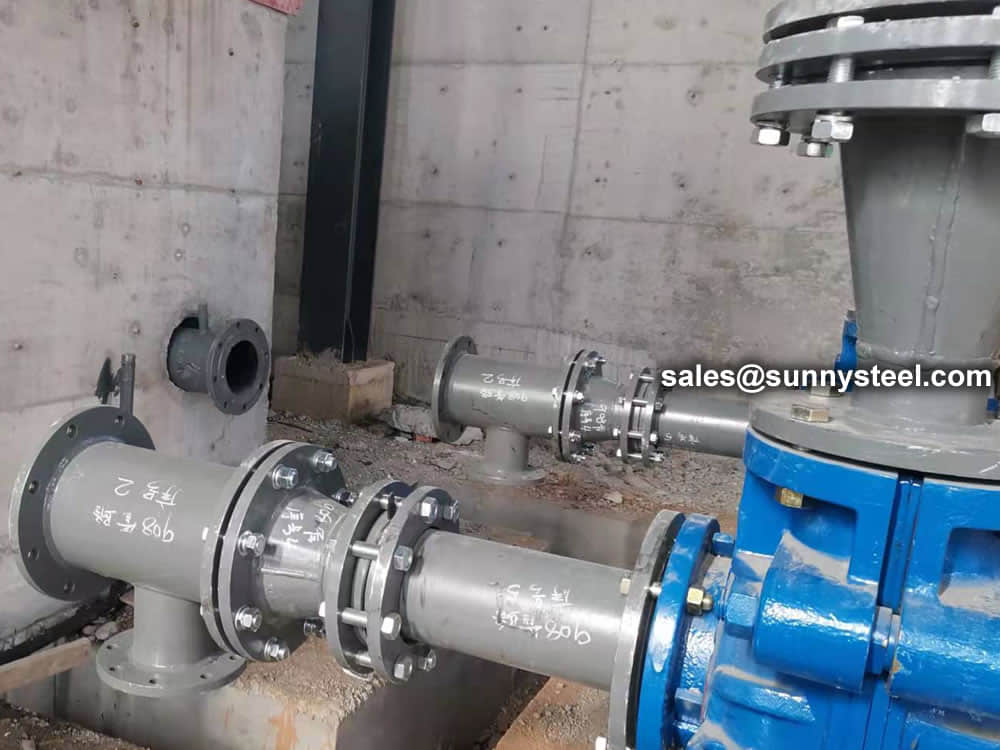

Alumina ceramic lining is often used in industrial settings to protect equipment from abrasion, corrosion, and wear caused by the flow of abrasive materials. The installation site is where these lined components are put into place within an industrial facility. This could include areas such as chutes, pipes, tanks, or other equipment that benefit from the added protection of alumina ceramic lining. The installation ensures that the equipment is properly lined and functioning as intended to enhance its durability and lifespan in challenging environments.

| Ash Pipe & Elbows | Add-Mix Transport Lines | Coal Piping Clinker Chutes |

| Chutes | Coal Conduit Lining | Coal Handing Chute Lining |

| Fan Lining | Pulverizer Housing Liner | Coal Mill Pulverizer Cone Lining |

| Bumer Feed Pipes | Classifer Cone Lining | Cullet Chutes & Hoppers |

| Cyclone Lining | Downcomer Pipe Lining | Coal Mill Exhauster Lining |

| Fan Housings | Drag Convey or Lining | Coal Mill Pulverizer Lining |

The ceramic alumina pressure has superior performance against abrasion,wich has five times more resistant than the conventional ceramic. If the objective is protection of components and reduced maintenance costs,the correct application of anti-abrasive lining led immediately to track the economy. If the objective is protection of components and reduced maintenance costs,the correct application of anti-abrasive lining led imediately to track the economy.

The ceramic pipe lining of hydraulic and pneumatic conveying transport has efficiency and economy,especially in steel tubes.Where they have great advantages, increasing the time of life.

A cross section of a steel pipe after 1 year of used

The perfect choice Resistance to abrasion is superior to all material available on the market

Metals have good ductility but poor resistance to abrasion - which means that abrasion prevention is required when metal pipes are used in high-temperature fluid catalyst service. On the other hand, ceramics possess great hardness and abrasion resistance, but they are brittle. Metal Ceramic double pipe is a hybrid pipe using metal as an outer pipe and a ceramic material for inner pipe segments, applied together to utilize the two materials' advantages. Hence excellent wear-resistance and good corrosion resistance of the ceramics and high strength and toughness of metal can be well combined to get a comprehensive advantage of wear-resistance, corrosion-resistance and anti-scaling. They are suitable for applications in heavy wear working conditions.

Ceramics are among the hardest materials available and provide ultimate wear resistance in piping. In high wear applications, ceramic lined pipes have been demonstrated to be cost-effective by increasing service life and reducing maintenance costs. Sunny Steel supply ceramic lined abrasion resistant steel pipes to your custom dimensions and budget. Our ceramic linings are the highest quality materials available to ensure that we provide the most cost-effective solutions for our clients.

Ceramic tile-lined pipes are indeed utilized in power plants in Vietnam . These pipes are designed with a ceramic lining inside a steel pipe to provide exceptional wear and corrosion resistance in high-abrasion environments.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.