Straight Pipes With Ceramic Lining

Alumina Ceramic Lined Straight Pipes prevents the pipes from wear and erosion.

Ceramic lined pipe is a type of pipe that is lined with ceramic to protect the inner surface of the pipe against wear and corrosion.

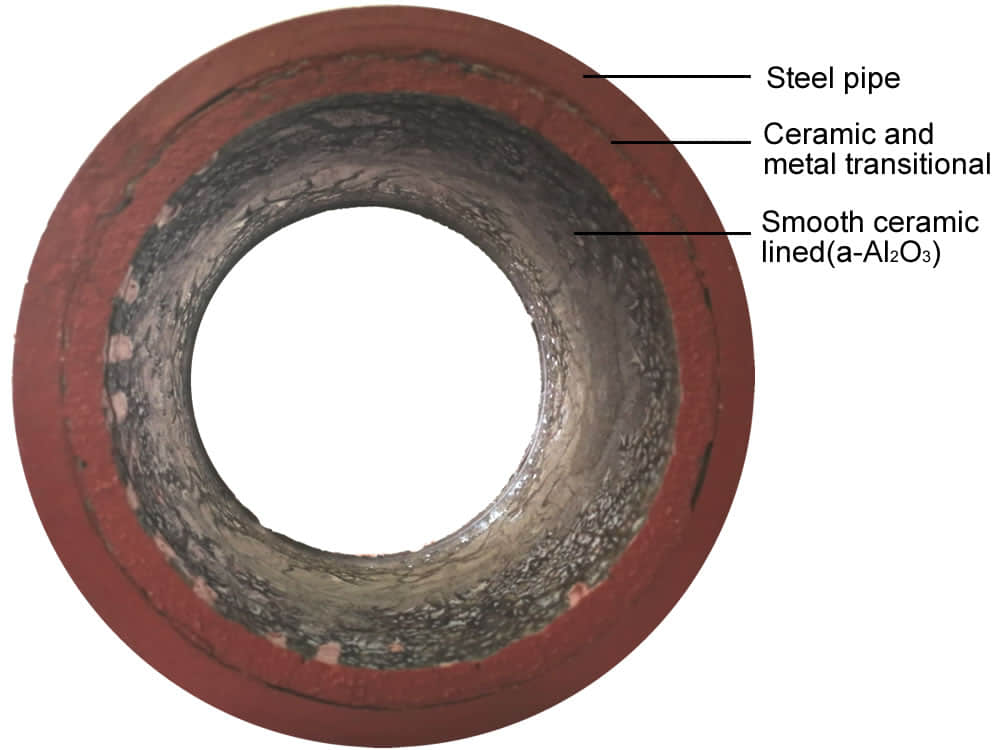

Self-propagating high temperature synthesis technology of corundum ceramic composite steel pipe is that is, "SHS" technology composite, is a national High-tech "863" project, is the original national metallurgical Industry Department, the Ministry of Electricity Project focused on the promotion of new products, the tube from within to outside by ceramic (corundum) layer, transition layer and steel layer composed of three parts.

Ceramic composite pipe due to corundum ceramic (a-AL2O3), Mohs hardness of 9.0 is equivalent to more than HRC90. Therefore, it has high wear resistance for abrasive media conveyed by industries such as metallurgy, electric power, mining, and coal. It has been confirmed by industrial operation that its wear life is ten times or even several ten times that of hardened steel.

SHS ceramic composite pipe is not like a convex spiral line on the inner surface of a seamless steel pipe because the inner surface is smooth and never corrodes. The inner surface roughness and clear water resistance characteristics of the relevant test units were tested. The smoothness of the inner surface was better than that of any metal pipe. The clear drag coefficient was 0.0193, which was slightly lower than the seamless pipe. Therefore, the tube has the characteristics of small running resistance and can reduce operating costs.

Since the steel ceramic layer is (a-AL2O3), it is a neutral characteristic. Therefore, it is resistant to acid and alkali and seawater corrosion, and it also has anti-scaling properties.

Due to the corundum ceramic (a-AL2O3), it is a single stable crystalline structure. Therefore, the composite pipe can operate normally in the long-term temperature range of -50--700°C. Material linear expansion coefficient of 6-8 × 10-6/0C, about 1/2 of the steel pipe. The material has good thermal stability.

Ceramic composite pipes are light weight and affordable. It is 50% lighter than the cast stone tube with the same inner diameter; it is 20-30% lighter than the wear-resistant alloy tube, and it has good wear resistance and corrosion resistance because of its long service life, thus supporting hanger costs, transportation costs, installation fees, and Reduce operating costs. Comparing the project budget of the design institute and construction unit with the actual project, the project cost is equivalent to the cast stone. Compared with the wear-resistant alloy pipe, the project cost is reduced by about 20%.

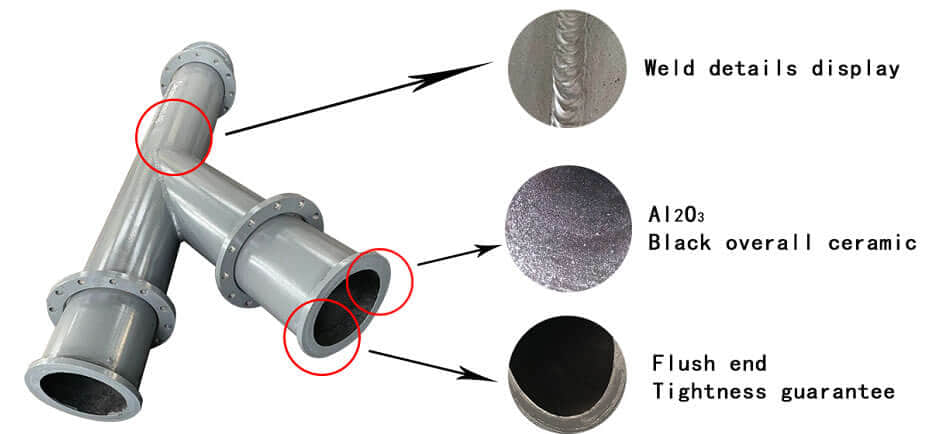

Because of its light weight and good welding performance. Therefore, welding, flanges, quick coupling, etc. can be adopted, and the construction and installation are convenient, and the installation cost can be reduced.

Ceramic steel pipe and traditional steel pipe, wear-resistant alloy cast steel pipe, cast stone pipe, as well as steel plastic, steel rubber pipe, etc. have essential differences. The outer layer of ceramic steel pipe is steel, and the inner is corundum. The Vickers hardness of corundum layer is as high as 100-1500 (Rockwell hardness is 90-98), which is equivalent to tungsten cobalt hard gold. The wear resistance is more than 20 times times higher than carbon steel pipe, it is superior to the corundum grinding wheel which is usually bonded. Now the corundum grinding wheel is still the main grinding wheel of the grinding mill. The corundum layer in the ceramic steel tube can wear away the corundum grinding wheel. The abrasion resistance of ceramic steel tube is mainly by the inner layer of several millimeters thick corundum layer, its Morse hardness is 9, second only to diamond and SIC, in all oxides, its hardness is the highest.

The inner liner ceramic wear-resisting steel pipe is made by SHS high temperature synthesis-centrifugal method, the melting point of corundum in ceramic steel pipe is 2045 ℃, the corundum layer and steel layer have special structure and stress field because of the process reason. Under normal temperature, the compressive stress of the ceramic layer, the tensile stress of the steel layer, the two opposites, into a balanced whole. Only when the temperature rises to more than 400 ℃, because the thermal expansion coefficient is different, the new stress field produced by the thermal expansion and the original stress field in the ceramic steel pipe cancel each other, so that both the ceramic layer and the steel layer are in a free equilibrium state. When the temperature rises to 900 ℃ the inner liner ceramic wear-resistant steel pipe into the water, repeatedly soaked repeatedly, the composite layer does not crack or cracking, showing the incomparable thermal shock resistance of ordinary ceramics. This performance is of great use in construction, because the outer layer is steel, in addition to heating the inner layer does not crack, in the construction, the flange, blowing, explosion-proof doors can be welded, but also can be directly welded to connect, which is more than wear-resistant cast stone pipe, wear-resistant cast steel pipe, Rare-earth wear-resistant steel pipe, bimetal composite pipe, steel pipe, Steel rubber pipe In the construction is not easy to weld or welding more than a chip. Internal liner ceramic Wear-resistant steel pipe resistance to mechanical impact is good, in transport, installation beat and the two support between the weight bending deformation, the composite layer does not break off.

At present, the practice of dozens of thermal power plants shows that the wear resistance of the inner-lined ceramic steel tube is high, and the resistance to fluid scouring is strong. In the first air duct, the bending pipe wear the most quickly, the wear resistance of the inner liner ceramic wear-resisting steel pipe is more than 5 times times higher than that of the thick wall wear-resisting cast steel elbow.

In practice, the inner liner ceramic wear-resistant steel pipe after 1-2 years to open observation and measurement, the composite layer has no obvious wear or fall off, in the same size and unit length of the pipeline, the internal liner ceramic wear-resistant steel tube weight only wear-resistant cast steel pipe or bimetal composite pipe of about 1/2, the cost of each of the meters reduced 30–40%, Only cast stone pipe and Rare-earth wear-resistant steel pipe weight of about 2/5, per meter project cost reduction of more than 20%. In the corrosive or high-temperature place to use the liner ceramic wear-resistant steel pipe, its price is only a stainless steel tube, nickel-titanium tube of a fraction of.

Fluid pipeline transportation is not only used in the power industry, but also in metallurgy, coal, petroleum, chemical, building materials, machinery and other industries. When the pipe is transported with large grinding material (such as ash residue, pulverized coal, mineral fine powder, tailings cement, etc., there is a problem of fast abrasion of pipe, especially the bending pipe wear fast; when conveying a strong corrosive gas, liquid or solid in the pipeline, there is a problem that the pipeline is corroded and destroyed quickly. When conveying the material with high temperature in the pipeline, there are some problems such as the price of heat-resisting steel pipe is very expensive. The internal liner ceramic wear-resistant steel pipe market, these problems are solved.

A ceramic lined pipe is a type of pipeline that has an inner lining made of ceramic material to provide superior resistance to wear, abrasion, and corrosion. The ceramic lining is typically made of high-grade alumina ceramics, which are known for their hardness, strength, and durability.

Ceramic lined pipes are commonly used in industrial applications where the pipeline is exposed to harsh conditions, such as in mining, power generation, oil and gas, and chemical processing. The ceramic lining provides exceptional wear resistance, protecting the underlying steel or cast iron pipe from premature failure due to abrasion or corrosion.

In addition to their excellent wear properties, ceramic lined pipes may also provide benefits such as improved flow rates, reduced downtime, and lower maintenance costs. They may also be used in applications where hygiene is important, as the ceramic lining is non-toxic and does not react with most chemicals.

Ceramic lined pipes may be manufactured in various sizes and shapes, including elbows, tees, and reducers, to meet the specific requirements of each application. The ceramic lining may be adhered to the inner surface of the pipe using specialized adhesives, and may be installed using conventional welding or mechanical joining techniques.

While ceramic lined pipes can offer significant benefits in terms of wear resistance and longevity, they are typically more expensive than traditional steel pipes due to the cost of the ceramic lining and specialized manufacturing processes.

The ceramic lined pipe transport has been widely used in the industries of electric power, metallurgy, coal, petroleum, chemical engineering, building materials, mechanism and so on.

The ceramic lined elbow throughout the power, metallurgy, coal, petroleum, chemical, building materials, machinery and other industries, and high-speed development. When lining the wear-resistant ceramic elbow to deliver high grinding material (such as ash, coal, ore powder, etc.), there is a lining of wear-resistant ceramic elbow wear fast, especially the elbow Wear faster. When lining a The ceramic lined elbow to deliver a highly corrosive gas, liquid or solid, there is a problem that the lined wear-resistant ceramic elbow is corroded and is quickly damaged.

There is a problem that it is expensive to use a heat-resistant steel pipe when the material having a higher temperature is conveyed in the lining of the wear-resistant ceramic elbow. After lining the wear-resistant ceramic elbow, these problems are solved.

The ceramic lined elbow is widely used in wear and tear of the mine filling material, ore powder and tailings transport, coal-fired power plant powder, smelting, ash and other lined with wear-resistant ceramic elbow is also very appropriate.

The ceramic lined pipe, Elbows, Reducer, Tees and others manufactured in our factory have been used in over 200 thermal power plants, more than 50 mines and the industries of coal, building materials, mechanism, petroleum and so on.

The abrasion pipe of thermal power plant is mainly conveying raw coal powder, ash slag, flue gas desulfurization (FGD) limestone powder and slurry, due to the transmission of medium velocity fast, poor operating conditions, resulting in pipelines, especially elbow, variable diameter pipe serious wear and corrosion, not only consumes a lot of metal materials, but also to the thermal power plant security, economic operation has brought hidden dangers. The abrasion mechanism of pipeline is mainly based on erosion wear. Wear-resistant pipe can be divided into two categories: single metal pipe and composite pipe.

Hoop strength is the resistance against radial pressure. The strength of the ceramic -lined steel composite pipe is 300 to 500MPa.

| Item | Index |

|---|---|

| Content of Alumina | ≥95% |

| Density | ≥3.5 g/cm3 |

| Rockwell Hardness | ≥80 HRA |

| Impact Strength | ≥850 Mpa |

| Bending Strength | ≥290MPa |

| Breaking Temper | ≥4.8MPa·m1/2 |

| Coefficient of Linear Thermal Expansion | 20W/m.K |

| Items | Index |

|---|---|

| Alumina content | 92% |

| Bulk Density | 3.62g/cm³ |

| Rockwell Hardness (HRA) | 90 |

| Compressive Strength | 850MPa |

| Fracture Toughness | 4.8MPa.M1/2 |

| Bending Strength | 290MPa |

| Thermal Conductivity 20℃ | 20W/m.k |

| Coefficient of Thermal Expansion | 7.2×10-6m/×m.k |

| Young's Modulus 20℃ | 277GPa |

| Shear Modulus 20℃ | 113GPa |

| Surface Finish: As Fired | 1.27mm |

Wear-resisting bend (wear resistant ceramic pipe)just as its name implies is a relatively traditional is more wear-resisting bend (wear resistant ceramic pipe), adopted the new wear-resistant plastic production, used in large industrial, currently occupies the market share of around 80%.

Ceramic lined is an application that provides protection for materials in environments that experience exposure to extreme chemicals and temperatures.

Ceramic lined refers to a material or surface that has a layer of ceramic applied to it. This ceramic layer provides protection against wear, corrosion, and abrasion, making it ideal for use in industrial applications where harsh conditions can cause damage to equipment over time. Ceramic lining is commonly used in pipes, tanks, and other equipment used in chemical processing, mining, and power generation industries.

Ceramic liner pipe is a high technology production technology-self-fuel high temperature clutch synthesis method.

Ceramic Liner Composite pipe is a high technology production technology-self-fuel high temperature clutch synthesis method. The tube is composed of corundum ceramics, transition layer and steel three layers respectively from inside to outside, the ceramic layer is formed dense corundum porcelain (Al2O3) at high temperature above 2,200 ℃, and the steel pipe is formed firmly by the transition layer.

Ceramic lined pipe through the inner lining of corundum ceramic (A-al2o3), the Mo hardness of up to 9.0 of the equivalent HRC90. Therefore, the metallurgical, electric power, mining, coal and other industries to transport the grinding media has high wear resistance. The industrial operation confirms that its wear resistance life is 10 times or even dozens of times that of quenched steel.

Corundum ceramic wear-resistant tube in the inner surface of smooth, and never rust, nor like seamless steel tube inside the surface has convex spiral. After testing the internal surface roughness and water resistance characteristics of the test units, the smoothness of the internal surface is superior to any metal pipe, the resistance coefficient is 0.0193, slightly lower than the seamless pipe.

As the steel ceramic layer is (A-al2o3), it is a neutral property. Therefore, with acid and alkali resistance and seawater corrosion, and at the same time with anti-scaling and other characteristics.

The corundum ceramic (A-al2o3) is a single stable crystalline structure. Therefore, the composite pipe can work in the temperature range of -50--700℃ for a long time. Material linear expansion coefficient 6-8x10-6/0c, about 1/2 of steel pipe.

Corundum ceramic wear-resistant pipe light weight, the price is suitable. The cast iron pipe with the same inner diameter is lighter than 50%, and lighter than that of wear-resistant alloy pipe 20-30%.

Due to the light weight of the pipe and good welding performance. Therefore, welding, flange, quick connection and so on, construction and installation is convenient.

Ceramic lined pipe with the traditional steel pipe, wear-resistant alloy cast steel pipe, cast stone pipe, as well as steel-plastic, steel-rubber pipe, etc. have essential differences. The outer layer of ceramic steel pipe is steel, and the inner layer is corundum. The Vickers hardness of the corundum layer is as high as 100-1500 (Rockwell hardness is 90-98), which is equivalent to tungsten cobalt hard gold. The wear resistance is more than 20 times higher than that of carbon steel pipe, it is superior to the corundum grinding wheel which is usually bonded.

Nowadays, the corundum grinding wheel is still the main grinding wheel of the mill. The corundum layer in the ceramic steel tube can wear away the corundum wheel. The abrasion resistance of the ceramic steel tube is mainly due to the inner layer of several millimetres thick corundum layer, its Morse hardness is 9, second only to diamond and SIC, in all oxides, its hardness is the highest.

There are probably hundreds of different methods for packing a abrasion resistant pipe and Elbows, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.

Wear-resistant ceramic composite pipe, full name ceramic liner composite steel pipe, is a kind of ceramic composite steel pipe.

Ceramic (Corundum: a-Al2O3) lined abrasion resistant straight pipe and fittings are lined with highly abrasion resistant ceramic by SHS -------Self-propagating High-temperature Synthetic process.

A small amount of iron also remains in the ceramic layer. There is a thin equiaxed grain area of alumina near the steel pipe wall, and then alumina was grown in form of dentrite to the surface of ceramic layer.

When abrasive material is transported through steel pipe in mining applications, typically as pumped slurry, the pipe can quickly be eroded from the inside out, which in more extreme cases can result in pipe leaks and even failure, or significant maintenance costs and downtime for pipe replacement.

Section of the composite pipe

Microstructure of ceramic layer

FeAl2O4 distributes among alumina dentrite. Although the ceramic layer was solidified from one end to another end of a pipe, the microstructure of ceramic layer was almost uniform throughout the whole length of the pipe.

Resistance to thermal shock

A composite elbow was used

in a mining plant for about

fifty thousands hours.

Hoop strength

Hoop strength is the resistance against radial pressure. The strength of the ceramic -lined steel composite pipe is 300 to 500MPa.

Compression-Shear strength

Compression-shear strength is the bonding strength at the interface between the ceramic layer and the steel pipe. The compression-shear strength of the ceramic-lined composite pipe is 15 to 20MPa.

Resistance to mechanical shock

The ceramic layer does not crack or flake off when the composite pipe receives a mechanical shock.

Resistance to thermal shock

The ceramic layer does not crack or flake off when heated to 800℃ and then quenched.

Resistance to abrasion

The ceramic-lined steel composite pipe has exceptional resistance to abrasion. Its service life in materials transportation with hard abrasives is more than 20 times longer than in common steel pipe.

For these abrasive applications, mild steel pipe is not tough enough to stand up to the abuse for more than a year or two. As a result, maintenance engineers are seeking superior piping alternatives to reduce maintenance and prolong system life, at a price point that will not significantly impact the budget.

The general servicelife of common steel elbow is about 700 hours.

The ceramic-lined steel composite pipe can be joined by welding the steel pipe layer.

The ceramic-lined steel composite pipes are lighter than alloy pipes, cast iron pipes, and cast stone pipes, which reduces the expense of transportation and makes the pipes easier to install.

Good weld ability

The relative weight of the

composite pipe is about

40-50% lighter than that of the

caststone pipe

The ceramic-lined steel composite pipes can be easily connected by welding, or with flanges and soft easy connectors.

Convenient installation

The composite pipes have good corrosion-resistant. There is no evidence of corrosion filling the composite pipes with bitter for one year (left), but the common steel pipe under the same condition is corroded seriously (right).

Ceramic liner composite pipe is different from traditional seamless steel pipe, wear-resisting alloy cast steel pipe, cast stone pipe, steel plastic pipe and steel rubber pipe.

| Sand injection test | 30% Transfer test of sludge with SiO2 | ||

|---|---|---|---|

| Material | Volume diminution (cm3) |

Material | Volume diminution (cm3) |

| Ceramic lined Steel pipe | 0.0022 | Ceramic lined Steel pipe | 3 |

| Ceramic pipe Al2O397% | 0.0025 | S45C | 25 |

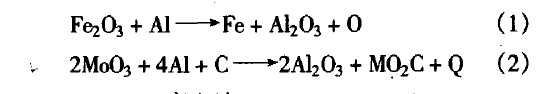

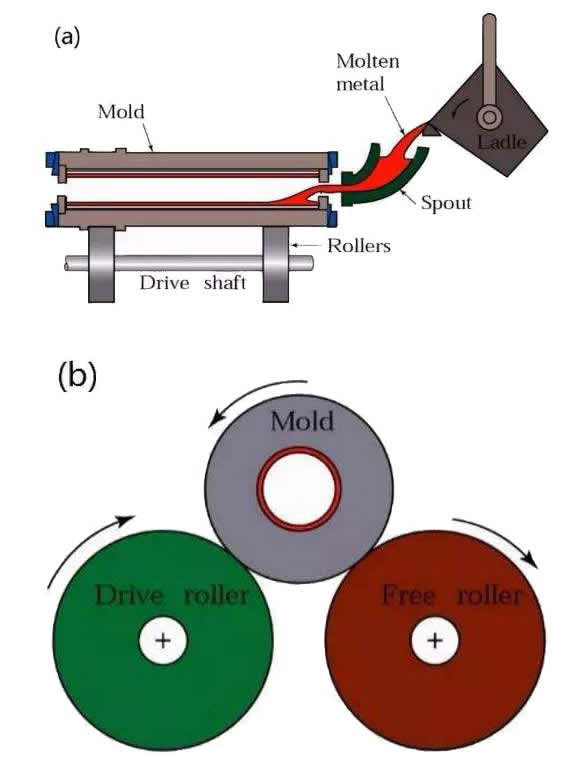

Self-propagating high temperature synthesis (SHS) is used to describe a process in which the initial reagents (usually powders), when ignited, spontaneously transform into products due to the exothermitic heat of reaction.

A well-known example of SHS reaction is the thermite reaction given below:

This reaction generates temperatures above the melting point of alumina and is used in the thermit welding process for joining railway lines.

Several other terminologies - such as combustion synthesis, gasless combustion or self-propagating exothermic reaction - are used to describe the process.

The types of material that can be formed using this process include metal borides, silicides, carbides, nitrides, sulphides, aluminides and oxides.

The combination of high rigidity of ceramic and high elasticity of steel gives the pipe unmatchable features as an abrasion resistant, heat resistant and corrosion resistant material for use in the fields of power generation, metallurgy, mining, and chemical industry etc.. It has many advantages over steel pipes, cast stone pipes, and steel-plastic compound pipes.

The composite pipe is composed of three layers: ceramic, intermediate, and steel layers. The ceramic layer is formed by molten alumina at a temperature above 2500 degree.

The molten alumina produced from the reaction Fe2O3+2Al=2Fe+Al2O3 spreads on the inside wall of the steel pipe under the influence of a centrifugal force, then solidifies, so the ceramic layer has high density and smooth surface and bonds to the steel pipe. They are widely used to convey highly abrasive material such as fly ash and any other fine powder material in mine, thermo power generating, coal processing plant, metallurgy, construction, etc. The service life is 10 to 20 times longer than normal steel pipe.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.