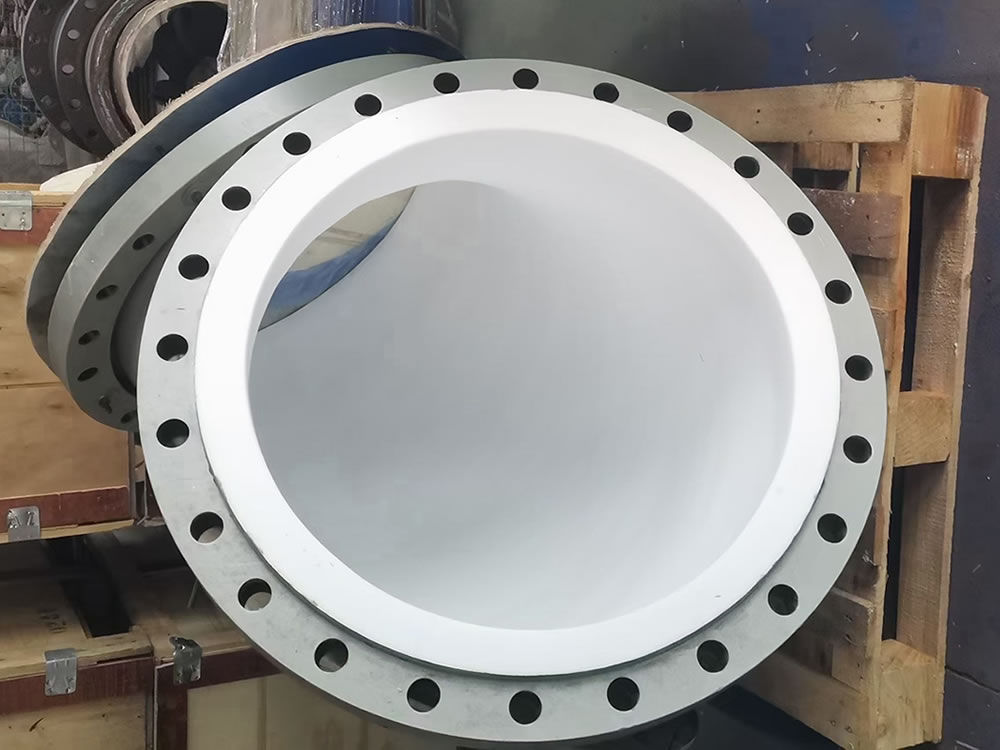

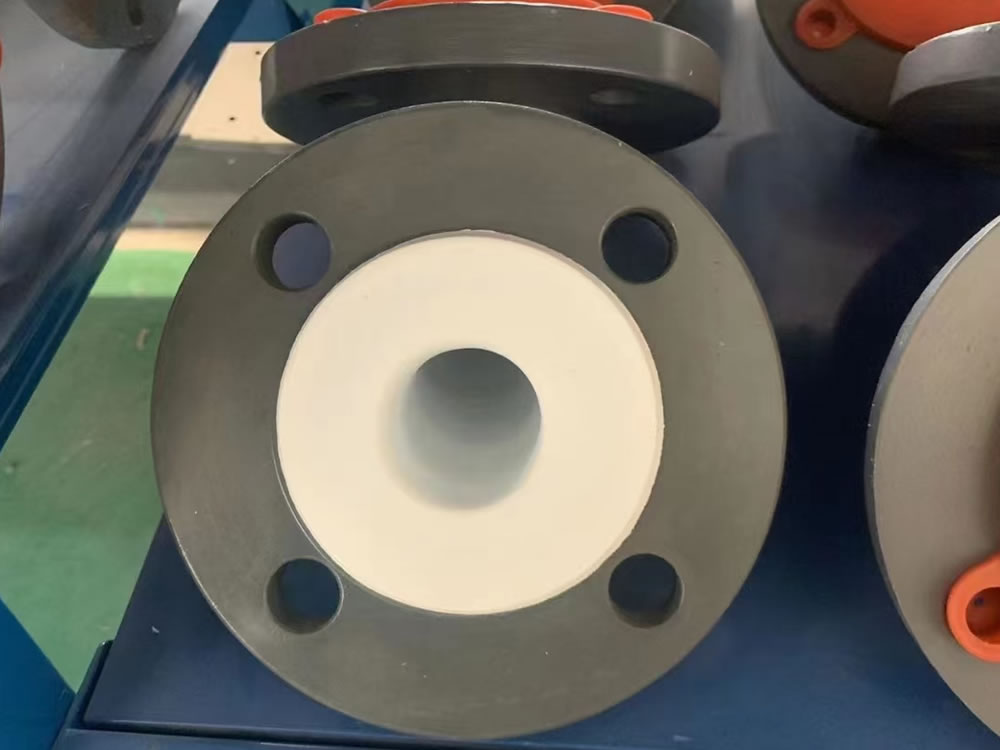

PTFE (polytetrafluoroethylene) pipe lining is a process in which the interior surface of pipes is coated or lined with PTFE material.

PTFE is a synthetic fluoropolymer known for its excellent chemical resistance, low friction properties, and high temperature resistance.

The PTFE lining provides excellent chemical resistance and low friction properties, making it suitable for handling corrosive fluids and high temperatures.

PTFE pipes and rollings – suitable for manufacturing of bushes, compressor rings, etc made from polytetrafluorethylene PTFE – stable and resistible material, chemically inert, non-flammable with high dielectric strength.

PTFE Tubing (PolyTetraFluoroEthylene tubing) is a semi-transparent, chemically inert, and non-toxic material that features unmatched temperature resistance and a surface that facilitates the flow of fluids. PTFE tubes are used applications requiring resistance to high temperatures, corrosive chemicals, and high voltages.

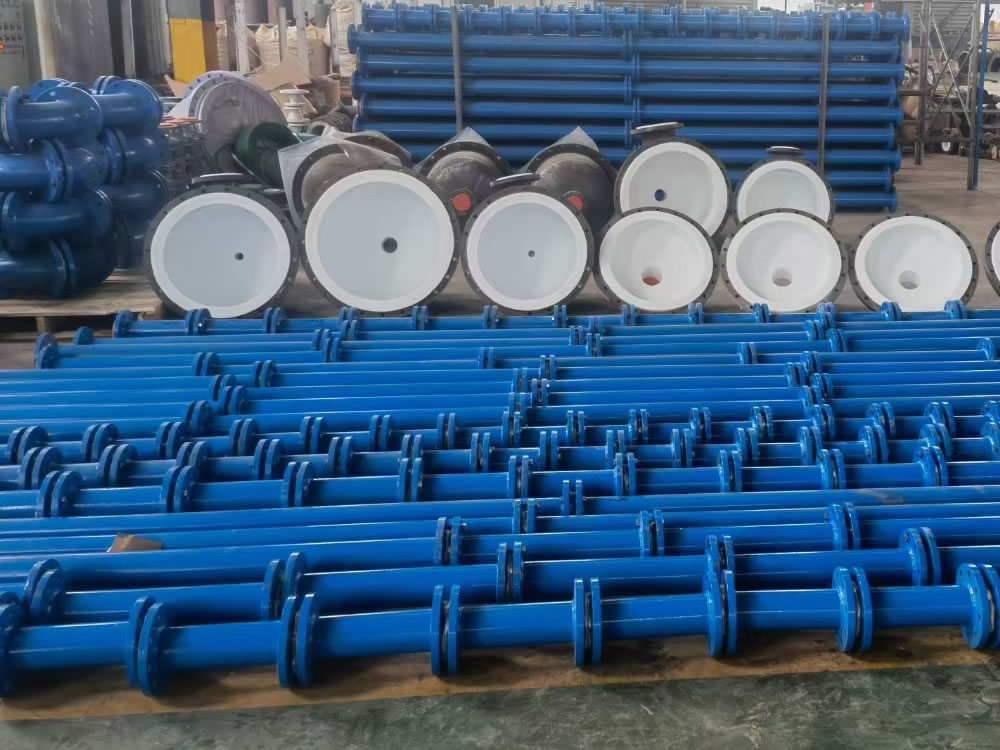

Unveiling our innovative PTFE pipe lining solutions, designed to revolutionize pipe protection. With superior durability and unmatched chemical resistance, our PTFE lined pipes redefine industry standards. Explore the perfect blend of reliability and performance as we introduce a range that goes beyond conventional expectations.

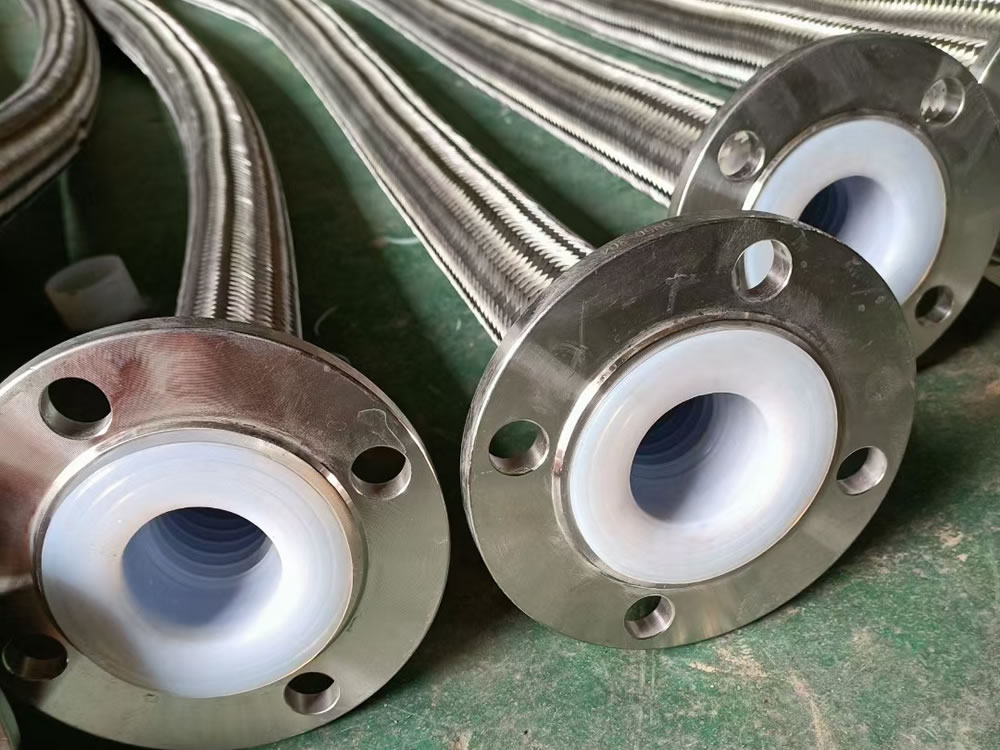

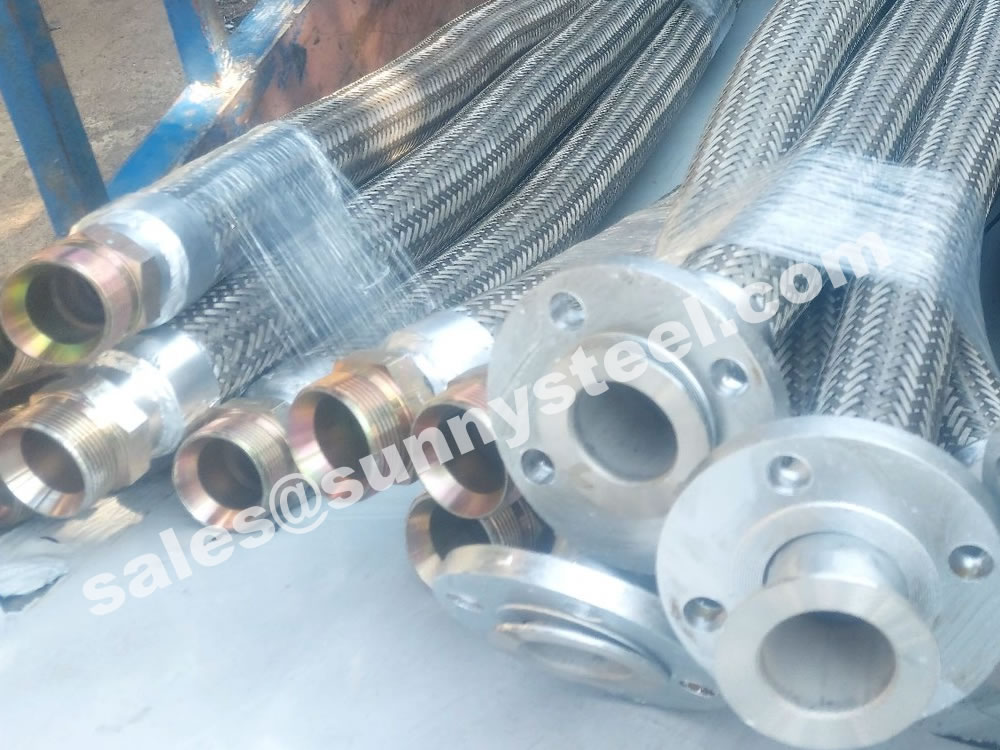

PTFE Hose is a highly versatile and durable alternative to rubber hose. PTFE (Polytetrafluoroethylene) serves as a liner for stainless steel braided hose or rubber hose, enhancing temperature range compatibility, chemical resistance, flexibility, and shock resistance.

PTFE lined hoses are used in a variety of demanding applications where chemical inertness, purity, and resistance to corrosion are important. They are commonly used in industries such as chemical processing, pharmaceuticals, food and beverage, and industrial applications. TFE hoses are highly resistant to most chemicals and they do not often release fumes, which is important for any kind of enclosed space. This chemical resistance also means that PTFE hoses will break down a lot more slowly than rubber hoses will.

Stainless steel flexible metal hoses are ready for packing and delivery.

PTFE lined rubber expansion joints are specialized pipe fittings used in various industries for their corrosion resistance and flexibility.

PTFE lined hoses are used in a variety of demanding applications where chemical inertness, purity, and resistance to corrosion are important. They are commonly used in industries such as chemical processing, pharmaceuticals, food and beverage, and industrial applications. TFE hoses are highly resistant to most chemicals and they do not often release fumes, which is important for any kind of enclosed space. This chemical resistance also means that PTFE hoses will break down a lot more slowly than rubber hoses will.

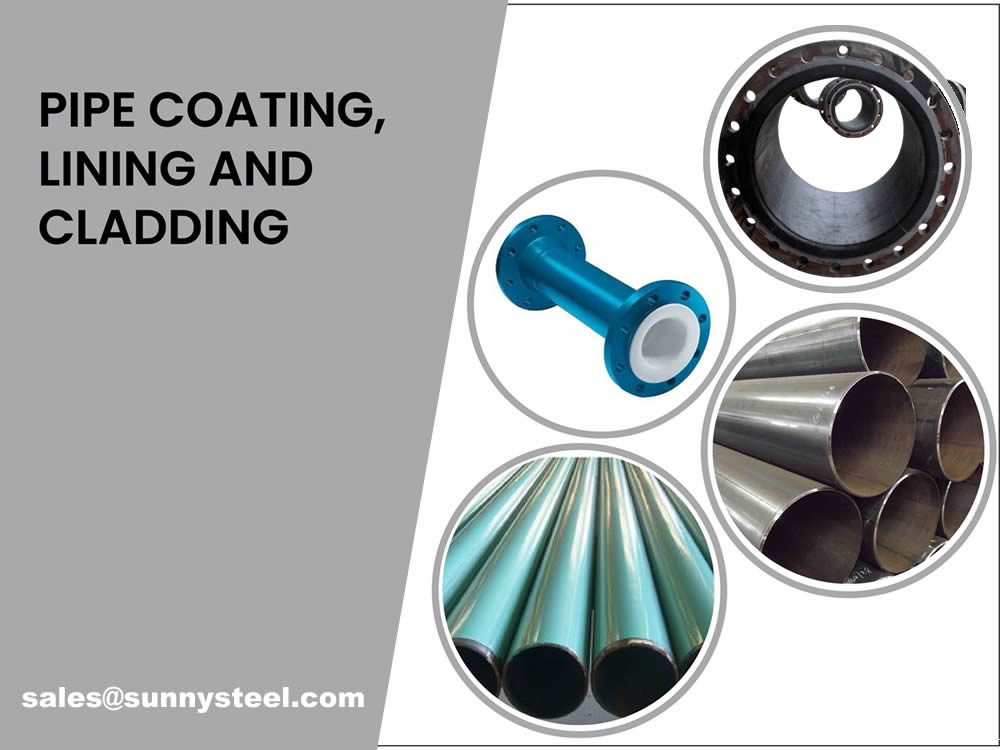

Pipeline coating is the most consistent and successful solution for protecting ERW pipes from corrosion, from moisture, other harmful chemicals.

Therefore pipe anti-corrosion layer is an important barrier to prevent soil erosion. A well-known foreign scholar put forward" 3PE france protective layer", so far, anti-corrosion methods is widely used.

Coated pipes offer high resistance to corrosion on pipes and provide many benefits such as:

1. Increased Flow Capacity – A coating on pipes helps provide a smoother surface thus improving gas and liquid flow within pipes.

2. Reduced Cost – The pipeline coating increases the pipes durability so they can be deployed with minimum maintenance cost even in the harshest environments.

3. Lower energy usage – Various studies have shown that pipelines that are internally coated use less energy for pumping and compression of products through pipes. This helps in increased saving over time.

4. Clean delivery of products – The inhibitors used for the protection products can also be minimized by the use of coated pipes for delivery of products.

Thus, coating of pipelines can help you in reducing your maintenance cost and at the same time providing a corrosion free reliable protection.

The basic principles of urban gas pipeline coating selection: