Single-layer pipe

Single-layer anti-corrosion epoxy powder pipe

IPN 8710 coating consists of polyurethane resin and modified epoxy resin and asphalt, anti-rust pigments and additives such as grinding precision filtration.

IPN8710 coating is a combination of polyurethane resin, modified epoxy resin, asphalt, anti-rust pigments, and additives. It is designed to provide excellent corrosion resistance and durability to steel pipes, particularly in applications involving water, gas, or other corrosive substances.

When the corrosion of steel in more types of media, such as acids, alkalis, salts, oxidants and water vapor, etc., the coating must be chemically inert, acid salt corrosion, the coating should be compact structure, water permeability, adhesion, tough fullness.

Water supply pipes within the wider variety of corrosive media, there is acid, alkali, salt, oxidizing and water vapor, etc., coatings must be chemically inert, acid and alkali salt corrosion, the coating should be compact and water permeability, strong adhesion , tenacity fullness.

IPN8710 primer: from polyurethane polyethylene, modified epoxy resin, non-toxic anti-rust pigment, filler, additives such as composition, room temperature curing to form interpenetrating networks, film structure, dense, acid, alkali, salt, rust-proof performance, strong adhesion.

IPN8710 finish: from epoxy, rubber and resin-modified, non-toxic anti-rust pigment, filler, additives etc.. Excellent chemical resistance, non-toxic, anti-microbial erosion.

Uses: IPN8710 primer for water supply pipeline wall corrosion grounding coating;

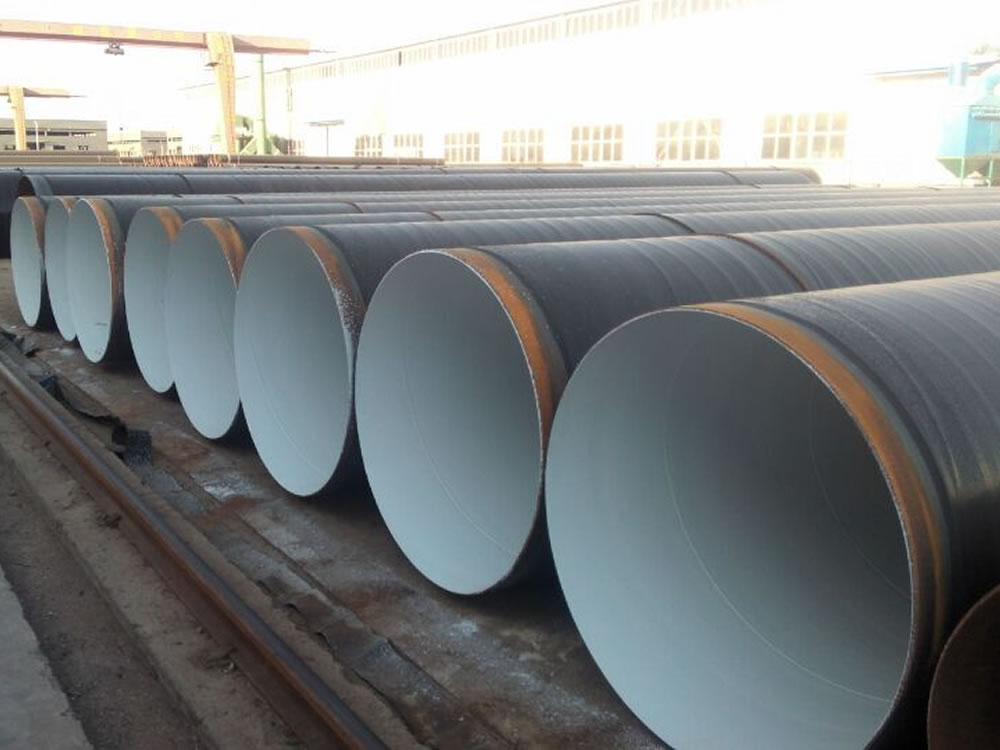

Diameter range is Φ325 - Φ2220

IPN8710 finish for water supply pipeline wall corrosion finish.

Anticorrosion pipeline is the preferred anti-corrosion steel pipe in water pipeline project, mainly used for urban water supply, water and other drinking water pipes.

There are many kinds of corrosive medium in water supply pipeline, such as acid, alkali, salt and oxidation IPN8710 anti-corrosion pipeline is the preferred water pipeline corrosion pipe, mainly for urban water supply, water and other drinking water pipes. There are many kinds of corrosive medium in water supply pipeline, such as acid, alkali, salt, oxidant and water vapor. The paint must have chemical lazy, acid and alkali salt corrosion. The coating should be fine, waterproof, Tough and plump.

Primer: Polyurethane, modified epoxy resin, non-toxic antirust pigment fillers, additives, etc., at room temperature curing constitute interpenetrating network, film structure fine, acid, alkali, salt, rust excellent , Strong adhesion

Topcoat: from epoxy, rubber resin modified, non-toxic anti-rust pigments, additives and other components. Chemical resistance Excellent, non-toxic, anti-microbial corrosion.

Pipeline in the transport and installation process may appear on the pipeline coating damage, pipeline installation and inspection after the end of the pipeline coating also need to fill the mouth injury 8710 anticorrosive coating Excellent water resistance, dedicated to food, drinking water and other equipment touched, transmission and distribution pipelines, drinking water tank exterior corrosion. Its acid and alkali, the temperature -40 ° -120 °, white non-toxic environmental protection, but also echoes the domestic environmental protection is now the principle of the request, and offer is not high, pipeline corrosion technology in a high cost-effective anti-corrosion technology.

IPN8710 coating offers several advantages. It has good corrosion resistance, low water absorption rate, and high mechanical strength. The coating is non-toxic and suitable for applications involving potable water IPN8710 coated pipes can be used for both above-ground and underground installations, providing reliable protection against corrosion.

IPN8710 coating is a specialized internal coating used for steel pipes, particularly in water supply systems. It's a combination of polyurethane resin, modified epoxy resin, asphalt, anti-rust pigments, and additives[_{{{CITATION{{{_1{Ipn8710 Drinking Water Seamless Steel Pipe](https://pipe.st.company/products/ipn8710-drinking-water-seamless-steel-pipe). This coating is designed to provide excellent corrosion resistance and durability, making it ideal for use in urban water supply, gas pipelines, and other applications involving corrosive substances[_{{{CITATION{{{_1{Ipn8710 Drinking Water Seamless Steel Pipe](https://pipe.st.company/products/ipn8710-drinking-water-seamless-steel-pipe).

IPN8710 coated pipes are commonly used in various industries, including water supply, gas transmission, and underground piping systems. The coating helps to protect the steel pipes from corrosion, extending their lifespan and maintaining the integrity of the pipeline.

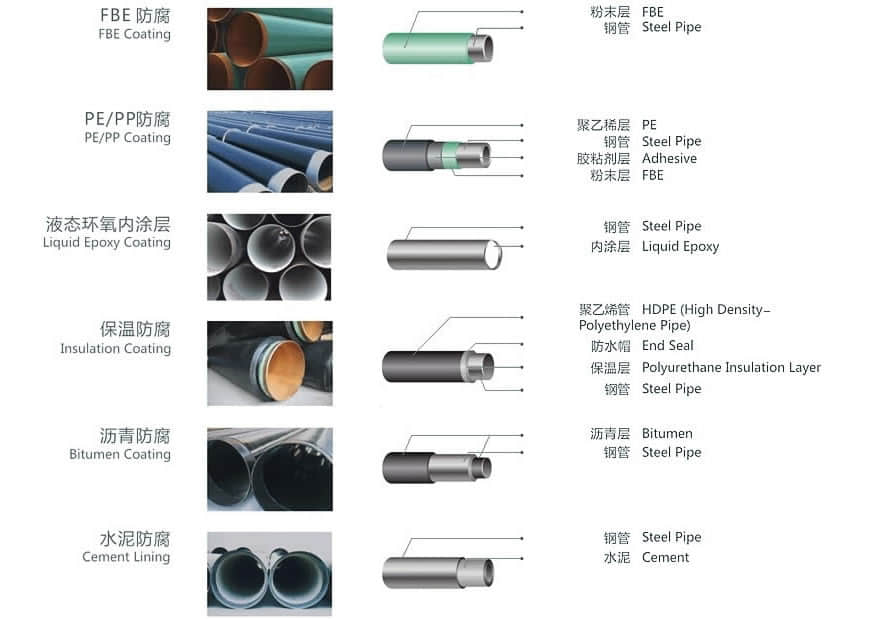

Some anti-corrosion methods include painting, covering, and electroplating.

Anti-corrosion coatings act as a barrier layer that prohibits or slows down the formation of corrosion on the underlying metal surface of the carbon steel pipe. By preventing external corrosion with the use of either single or multi-layer anti-corrosion coatings, it ensures precious natural resources and other products reach their destination safely and efficiently.

Anti-corrosion steel pipe is processed through the preservation process, which can effectively prevent or slow down the process in the transport and use of chemical or electrochemical corrosion reaction of steel pipe.

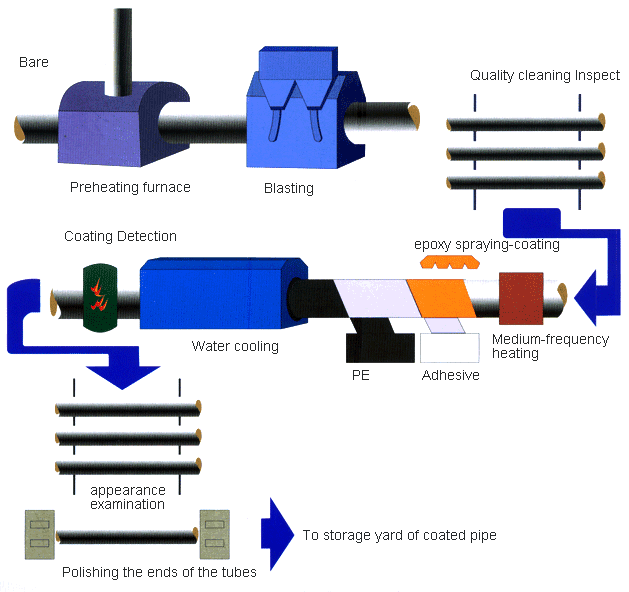

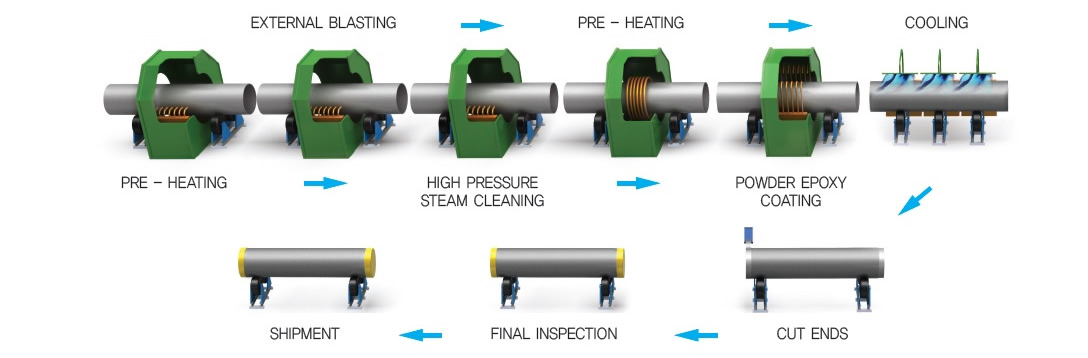

Steel surface treatment is mainly for anti - rust, and the following is the anti - rust process:

First step: Clean the steel surface using a cleaning solvent emulsion. This is to remove oil, grease, dust, lubricants, and similar organic matter. However, it cannot remove rust, oxides, or soldering agents on the steel surface.

Second step: Use rust - removing tools. You need to use a wire brush to remove loose or flaking oxides, rust, and slag. To achieve the desired rust - removing effect, the type of abrasive should be selected based on the original corrosion degree of the steel surface, the required surface roughness, and the coating. For an epoxy layer or two - or three - layer polyethylene coating, using a mixed abrasive of grit and steel shot for blasting is more likely to achieve the desired effect.

Third step: Perform pickling. Generally, chemical and electrolytic pickling are two methods. Using only chemical pickling can cause pipeline corrosion. Although chemical cleaning can achieve a certain level of surface cleanliness and roughness, it causes some environmental pollution.

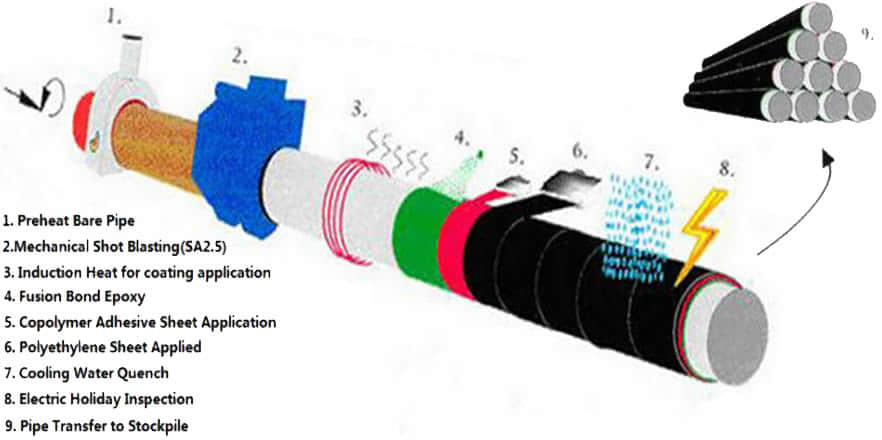

The three-layer PE (Polyethylene) and PP (Polypropylene) coating process is designed to enhance the corrosion resistance, durability, and mechanical strength of steel pipes.

Finally, emphasize the importance of surface treatment in production and strictly control the process parameters during anti - rust treatment.

When it comes to transporting precious natural resources or other essential products, the integrity of the pipes used plays a pivotal role. Carbon steel pipes, widely utilized in various industries, are susceptible to corrosion over time. This is where anti-corrosion coatings step in as the frontline defense, ensuring the longevity and reliability of the pipes.

Anti-corrosion steel pipe is processed through the preservation process, which can effectively prevent or slow down the process in the transport and use of chemical or electrochemical corrosion reaction of steel pipe.

Anti - corrosion coatings serve as a protective shield against the relentless forces of corrosion that can compromise the structural integrity of carbon steel pipes. These coatings act as a robust barrier layer, strategically designed to inhibit or significantly slow down the formation of corrosion on the metal surface.

In the realm of carbon steel pipes, the battle against corrosion is ongoing. Anti - corrosion coatings emerge as the frontline warriors, safeguarding the structural integrity of pipes and ensuring that resources and products reach their destinations without compromise.

To improve anticorrosion performance and adhesion, an additional layer of epoxy primer is sprayed onto pipe surfaces prior to the adhesive layer and Polyethylene top - layer application. Three Layer Polyethylene is suitable for service temperatures from 60°C to 80°C (85°C peaks). Typical coating thickness is from 1 - 2 mm to 3 - 5 mm.

If a wider service temperature range and high stiffness is required, adhesive and top layers, applied over the primer layer, are based on polypropylene instead of polyethylene. Three Layer Polypropylene is suitable for service temperatures up to 135 °C (140°C peaks). Typical coating thickness is from 1 - 2 mm to 3 - 5 mm.

Three - Layer applications involve a thermoplastic coating applied to steel pipelines as a form of anticorrosion protection. This mechanical resistance is appropriate when the risk of particularly severe coating damages exists. The Three - Layer process involves several steps. First, the pipe surface is blast - cleaned to remove any external residue from the mill or storage. It is then heated and sprayed with a Fusion Bond Epoxy (FBE) primer followed by the application of an adhesive copolymer and polyolefin polymers that are wrap - extruded, one over the other.

Pipeline coating is the most consistent and successful solution for protecting ERW pipes from corrosion, from moisture, other harmful chemicals.

Therefore pipe anti-corrosion layer is an important barrier to prevent soil erosion. A well-known foreign scholar put forward" 3PE france protective layer", so far, anti-corrosion methods is widely used.

1. Increased Flow Capacity – A coating on pipes helps provide a smoother surface thus improving gas and liquid flow within pipes.

2. Reduced Cost – The pipeline coating increases the pipes durability so they can be deployed with minimum maintenance cost even in the harshest environments.

3. Lower energy usage – Various studies have shown that pipelines that are internally coated use less energy for pumping and compression of products through pipes. This helps in increased saving over time.

4. Clean delivery of products – The inhibitors used for the protection products can also be minimized by the use of coated pipes for delivery of products.

Thus, coating of pipelines can help you in reducing your maintenance cost and at the same time providing a corrosion free reliable protection.

The basic principles of urban gas pipeline coating selection:

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.