Pipe Collar

High-quality Pipe Collars for various piping systems.

We produce pipe collars made from plates, with dimensions and tolerances in accordance with EN 1092-1 (Din 2642) or for lap joint flanges according to Asme B16.5.

Pipe collars are essential components in various piping systems, offering practical solutions for sealing and protecting pipes.

Collars are certified according to the following standards:

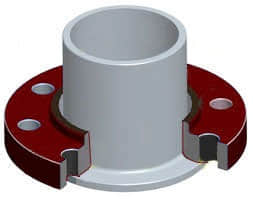

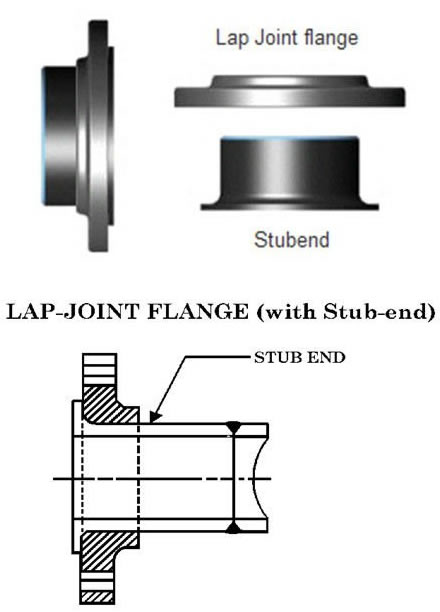

Lap joint stub end is a fitting that is used replace welded flanges when the support of a rotating back up flange is required. And It can be supplied in standard and non-standard ANSI dimension that is used for connecting pipes of different diameter.

Lap joint stub end must have high quality, and it posses features as below:

Lap-joint flanges are most commonly available in carbon steel and low temperature carbon steel, because it is a lower cost than the Stub End that will be wetted by the service and it must be of a suitable grade of steel. If orientation and alignment of bolt holes is the only issue, then for standardization, then the Stub End and the Lap Joint Flange can be of the same material.

The most common material grade for stub end is the ASTM A403 / ASME SA403 (stainless steel stub ends). With reference to EU materials, the most common grades are DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404.

Pipe collars are indispensable components in various industries and applications, offering a blend of functionality and aesthetics. From plumbing systems to fire protection, these versatile devices provide a practical solution for sealing pipe penetrations and ensuring the integrity of piping systems. With various types and materials available, selecting the right pipe collar for specific applications is crucial for optimal performance and safety.

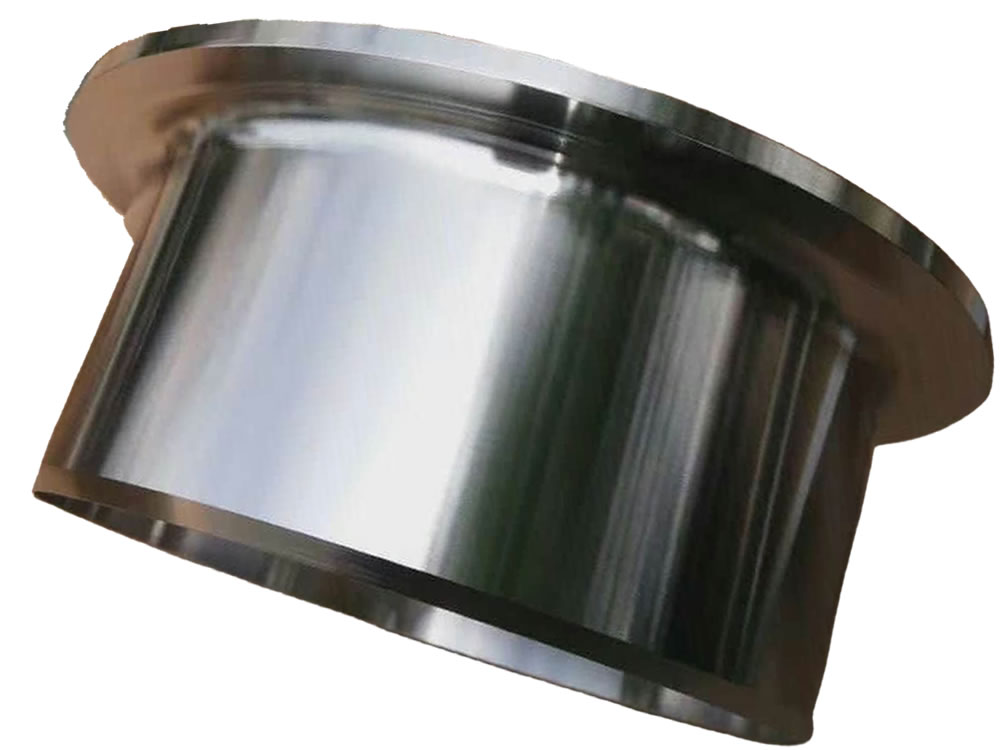

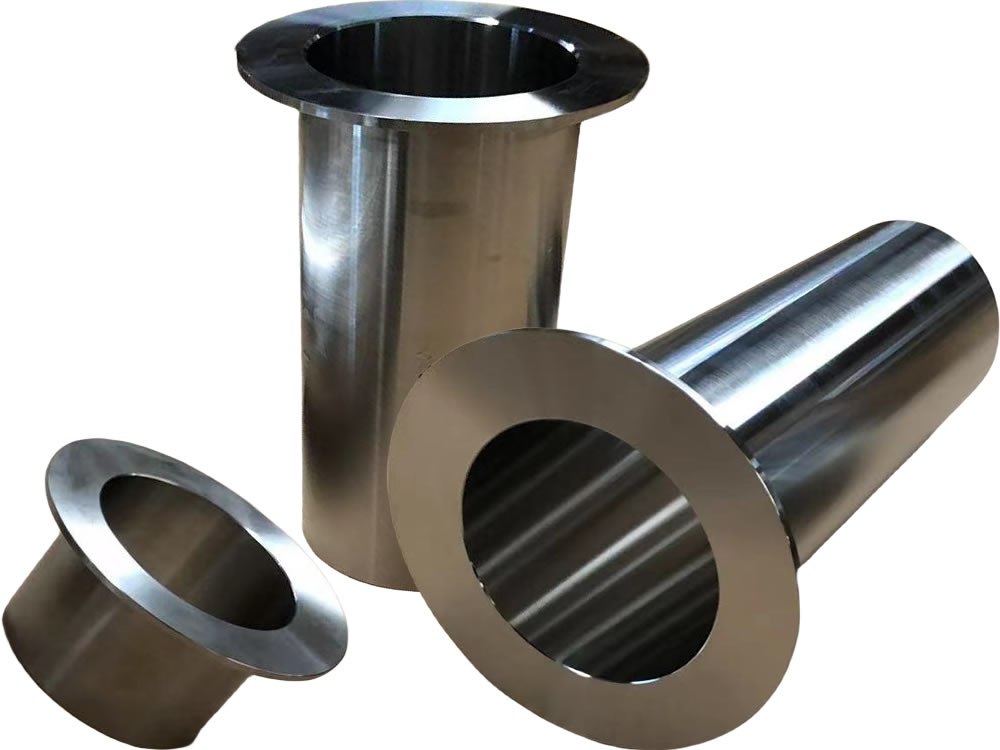

Stainless steel collar for loose flanges serves as the terminal part of the pipeline, connecting the steel pipe to a steel valve or shut-off valve by welding it to the pipe end.

This stainless steel collar is a unique component, serving as the intermediary between the pressure flange and the counter flange of the steel pipe, gate valve, or shut-off valve.

The stainless steel collar plays a crucial role in significantly reducing the construction costs of pipeline systems, especially when installing valves and other flange connections, particularly in cases involving large pipe diameters.

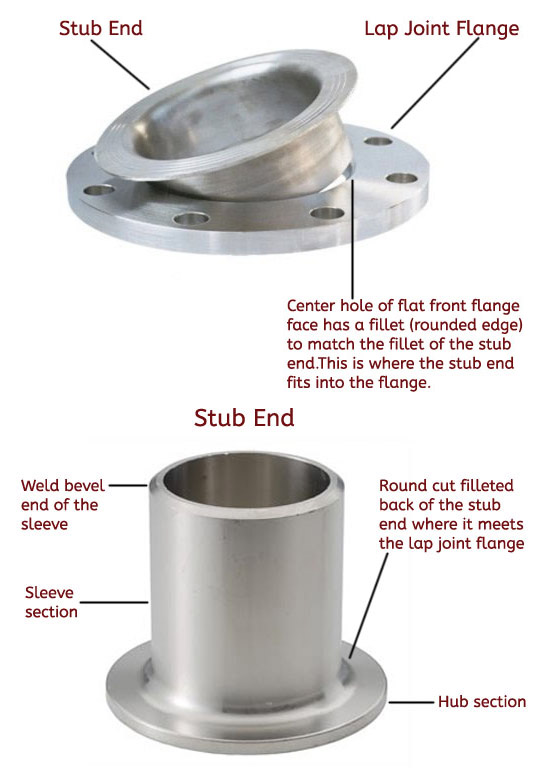

The stainless collar for flanges is an integral part of the Lap Joint Flange connection, which consists of two pieces. It resembles a combination of a weld neck flange and a loose slip-on flange and is butt-welded to the pipes. Lap joint flanges, along with the stainless collars, are commonly used in low-pressure piping systems.

In piping systems, a stub end is a crucial component used for connecting pipes of different materials and sizes. It provides a convenient and cost-effective solution for achieving a leak-free joint without the need for welding. In this article, we will explore the geometry, types, and applications of stub ends, shedding light on their significance in various industries and projects.

| N.D. | Out diamater | Hight(F) | Stub end O.D.(G) | Beveld radio(R) | ||||

|---|---|---|---|---|---|---|---|---|

| NPS | DN | OD | Mss | ANSI | Nominal&max | Nominal&min | A Max | B Max |

| 1/2 | 15 | 21.3 | 50.8 | 76.2 | 35 | 34 | 3 | 0.8 |

| 3/4 | 20 | 26.7 | 50.8 | 76.2 | 43 | 42 | 3 | 0.8 |

| 1 | 25 | 33.4 | 50.8 | 101.6 | 51 | 50 | 3 | 0.8 |

| 1 1/4 | 32 | 42.4 | 50.8 | 101.6 | 64 | 63 | 4.8 | 0.8 |

| 1 1/2 | 40 | 48.3 | 50.8 | 101.6 | 73 | 72 | 6.4 | 0.8 |

| 2 | 50 | 60.3 | 63.5 | 152.4 | 92 | 91 | 7.9 | 0.8 |

| 2 1/2 | 65 | 73 | 63.5 | 152.4 | 105 | 104 | 7.9 | 0.8 |

| 3 | 80 | 88.9 | 63.5 | 152.4 | 127 | 126 | 9.6 | 0.8 |

| 3 1/2 | 90 | 101.6 | 76.2 | 152.4 | 140 | 139 | 9.6 | 0.8 |

| 4 | 100 | 114.3 | 76.2 | 152.4 | 157 | 156 | 11.2 | 0.8 |

| 5 | 125 | 141.3 | 76.2 | 203.2 | 186 | 185 | 11.2 | 1.6 |

| 6 | 150 | 168.3 | 88.9 | 203.2 | 216 | 215 | 12.7 | 1.6 |

| 8 | 200 | 219.1 | 101.6 | 203.2 | 270 | 269 | 12.7 | 1.6 |

| 10 | 250 | 273.1 | 127 | 254 | 324 | 322 | 12.7 | 1.6 |

| 12 | 300 | 323.9 | 152.4 | 254 | 381 | 379 | 12.7 | 1.6 |

| 14 | 350 | 355.6 | 152.4 | 304.8 | 413 | 411 | 12.7 | 1.6 |

| 16 | 400 | 406.4 | 152.4 | 304.8 | 470 | 468 | 12.7 | 1.6 |

| 18 | 450 | 457.2 | 152.4 | 304.8 | 533 | 531 | 12.7 | 1.6 |

| 20 | 500 | 508 | 152.4 | 304.8 | 584 | 582 | 12.7 | 1.6 |

| 22 | 550 | 559 | 152.4 | 304.8 | 641 | 639 | 12.7 | 1.6 |

| 24 | 600 | 610 | 152.4 | 304.8 | 692 | 690 | 12.7 | 1.6 |

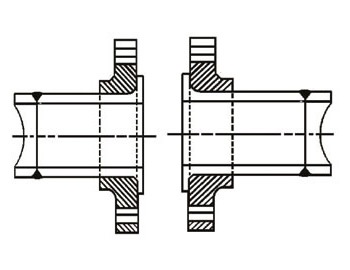

The Stub End, which essentially a short length of pipe, which has one end that is flared outwards and the other end prepared to be welded to pipe of the same Nominal Pipe Size (NPS), material and of a similar wall thickness. The Lap Joint Flange, which is a ring backing Flange and it is very similar in geometry to the Slip-on Flange.

Stub ends are mechanical joints that comprises of two components.

This type of flanged connection was also referred to as “Van Stone” or “Vanstone flare laps”, however this is an historic terminology and very rarely used technically or commercially.

For packing of carbon steel flanges with painting,we would use the bubble wrap to protect the painting.For flanges without painting or oiled with long-term shipment,we would suggest client to use the anti-tarnish paper and plastic bag to prevent the rust.

Stub ends and lap joint flanges can be assembled following this process:

It can also be mated to a fabricated plate Flange with compatible, bolting dimensions.

Duplex Stub End and a Duplex Lap Joint, you could have Duplex Stub End and Carbon Steel Lap Flange.

Or you could have Stainless Stub End and Carbon Steel Lap Flange. There are other bimetallic combinations that result in a flange assembly that is commercially cheaper.

During recent years the price differential between Duplex/Stainless Steel and Carbon Steel has narrowed and this practice on large Projects has become less common, however a cost difference always exists (the higher the NPS and the length of the pipeline / piping system, the higher the saving). On the other hand, the warehousing cost of one single component, i.e. a Weld Neck Flange, requires less shelf space than the cost of warehousing a Lap Joint and a Stub End. End Users and Contractors shall determine the actual convenience of using stub ends, considering all these factors and generally the commercial advantage is still valid and it may suit certain situation, especially in “brownfield” modifications.

The following information shall be provided to order a stub end:

Stub ends can be ordered with different ends finishing:

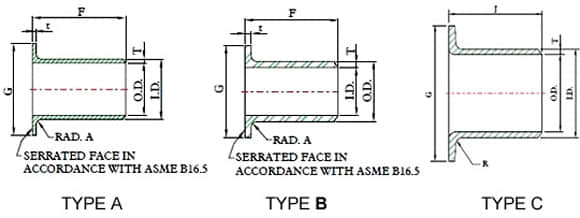

Stub end are offered in three different ways, type A, B and C. Type A and B stub end are similar to forged fittings, such as elbows and tees, and type C stub end are made in customized sizes.

Stub ends are manufactured in three different types and two standard length.

Type “A”: this type is produced and machined to fit lap joint flanges.The mating surfaces of the stub end and the lap joint flange have a matching profile and surface. The lap thickness of type A stub ends is > = the minimum wall thickness of the connected pipe. The outside the stub end and the lap joint flange have a matching profile and surface. The lap thickness of type A stub ends is > = the minimum wall thickness of the connected pipe. The outside corner of type A has a radius to accommodate the lap join flange, whereas the inside corner is squared.

Type “B”: this type of stub ends is suited for standard slip-on flanges acting as lap-joint flanges. The lap thickness of type B stub ends is >= the minimum WT of the connecting pipe. The lap of these type of stub ends has generally a serrated face. To ensure tight joints, chamfers on the ID side of the flange are required.

Type “C”: this last type can be used both with lap joint and slip-on backing flanges and are fabricated out of pipes. The lap of C-type stub ends is flared over and the lap thickness is 75% of the connecting pipe WT. Type C has a short fillet outer radius able to host any back up flange.

Type “CS”: this type is similar to “C” with the difference that the lap face has concentric serrations machined during the manufacturing process.

There are two main types of stub ends commonly used in piping systems:

Both long pattern and short pattern stub ends are available in various materials such as stainless steel, carbon steel, alloy steel, and others, making them suitable for different industrial applications. They provide a cost-effective and reliable solution for connecting pipes to flanges in piping systems.

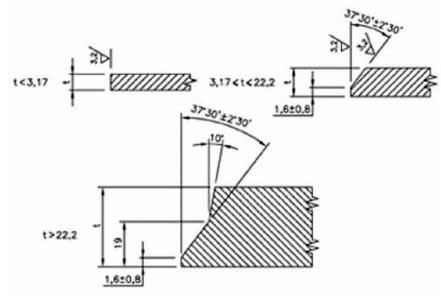

Dimensions and manufacturing tolerances are covered in ASME B16.9 – Butt Weld Fittings and MSS-SP-43 (JIS B2312, JIS B2313 may also apply).

Stub End come in three standard lengths, MSS SP43 or ANSI B16.9 short and long pattern. Short pattern stub ends are mostly used for flanges from class 300 to class 600 and above. Besides these standard types, End-Users and contractors can require stub ends with non-standard lengths to suit specific project’s requirement. This will of course come at an additional cost.

ASME B16.25 END WELDING BEVEL as right

The following types of ends may be ordered:

Beveled Ends (generally ASME B16.25)

Squared Ends

Flanged Ends

Victaulic Grooves

Threaded Ends (Male Only)

Pipe fitting dimensions are in either metric or Standard English.

Because pipe fitting covers Pipe Fitting Dimensions several aspects, only the most common pipe fitting sizes can be given here. The most applied version is the 90° long radius and the 45° elbow, while the 90° short radius elbow is applied if there is too little space. The function of a 180° elbow is to change direction of flow through 180°. Both, the LR and the SR types have a center to center dimension double the matching 90° elbows. These fittings will generally be used in furnesses or other heating or cooling units.

Some of the standards that apply to buttwelded fittings are listed below. Many organizations such as ASME, ASTM, ISO, MSS, etc. have very well developed standards and specifications for buttwelded fittings. It is always up to the designer to ensure that they are following the applicable standard and company specification, if available, during the design process.

Some widely used pipe fitting standards are as follows:

This is one of the reputed organizations in the world developing codes and standards.

The schedule number for pipe fitting starts from ASME/ANSI B16. The various classifications of ASME/ANSI B16 standards for different pipe fittings are as follows:

This is one of the largest voluntary standards development organizations in the world. It was originally known as the American Society for Testing and Materials (ASTM).

AWWA About – Established in 1881, the American Water Works Association is the largest nonprofit, scientific and educational association dedicated to managing and treating water, the world’s most important resource.

ANSI is a private, non-profit organization. Its main function is to administer and coordinate the U.S. voluntary standardization and conformity assessment system. It provides a forum for development of American national standards. ANSI assigns “schedule numbers”. These numbers classify wall thicknesses for different pressure uses.

The Manufacturers Standardization Society (MSS) of the Valve and Fittings Industry is a non-profit technical association organized for development and improvement of industry, national and international codes and standards for: Valves, Valve Actuators, Valve Modification, Pipe Fittings, Pipe Hangers, Pipe Supports, Flanges and Associated Seals

Piping codes imply the requirements of design, fabrication, use of materials, tests and inspection of various pipe and piping system. It has a limited jurisdiction defined by the code. On the other hand, piping standards imply application design and construction rules and requirements for pipe fittings like adapters, flanges, sleeves, elbows, union, tees, valves etc. Like a code, it also has a limited scope defined by the standard.

“Standards” on pipe fittings are based on certain factors like as follows:

BSP is the U.K. standard for pipe fittings. This refers to a family of standard screw thread types for interconnecting and sealing pipe ends by mating an external (male) with an internal (female) thread. This has been adopted internationally. It is also known as British Standard Pipe Taper threads (BSPT )or British Standard Pipe Parallel (Straight) threads (BSPP ). While the BSPT achieves pressure tight joints by the threads alone, the BSPP requires a sealing ring.

This is the Japanese industrial standards or the standards used for industrial activities in Japan for pipe, tube and fittings and published through Japanese Standards Associations.

National Pipe Thread is a U.S. standard straight (NPS) threads or for tapered (NPT) threads. This is the most popular US standard for pipe fittings. NPT fittings are based on the internal diameter (ID) of the pipe fitting.

We are manufacturer of Flange bolts & Nuts and supply high quality

The AN standard was originally designed for the U.S. Military. Whenever, a pipe fitting is AN fittings, it means that the fittings are measured on the outside diameter of the fittings, that is, in 1/16 inch increments.

For example, an AN 4 fitting means a fitting with an external diameter of approximately 4/16″ or ¼”. It is to be noted that approximation is important because AN external diameter is not a direct fit with an equivalent NPT thread.

Dash size is the standard used to refer to the inside diameter of a hose. This indicates the size by a two digit number which represents the relative ID in sixteenths of an inch. This is also used interchangeably with AN fittings. For example, a Dash “8” fitting means an AN 8 fitting.

ISO is the industrial pipe, tube and fittings standards and specifications from the International Organization for Standardization. ISO standards are numbered. They have format as follows:

“ISO[/IEC] [IS] nnnnn[:yyyy] Title” where

| Standard | Specification |

|---|---|

| ASTM A234 | Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service |

| ASTM A420 | Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Low-Temperature Service |

| ASTM A234 WPB | ASTM A234 WPB refers to a specific grade of carbon steel pipe fittings, which are widely used in pressure piping and pressure vessel fabrication for service at moderate and elevated temperatures. |

| ASME B16.9 | ASME B16.9 Standard covers overall dimensions, tolerances,ratings, testing, and markings for factory-made wrought buttwelding fittings in sizes NPS 1⁄2 through NPS 48 (DN 15 through DN 1200). |

| ASME B16.28 | ASME B16.28 Standard covers ratings, overall dimensions, testing, tolerances, and markings for wrought carbon and alloy steel buttwelding short radius elbows and returns. |

| MSS SP-97 | MSS SP-97 Standard Practice covers essential dimensions, finish, tolerances, testing, marking, material, and minimum strength requirements for 90 degree integrally reinforced forged branch outlet fittings of buttwelding, socket welding, and threaded types. |

| ASTM A403 | Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings. |

| DIN | EN | ASME |

|---|---|---|

| St 35.8 I St 35.8 III 15 Mo 3 13 CrMo 4 4 10 CrMo 9 10 St 35 N St 52.0 St 52.4 |

P235GH-TC1 P235GH-TC2 16Mo3 13CrMo4-5 10CrMo9-10 X10CrMoVNb9-1 P215NL P265NL L360NB L360NE P355N P355NL1 P355NH |

WPB WPL6 WPL3 WPHY 52 WP11 WP22 WP5 WP9 WP91 WP92 |

Precision-made 90-degree A403 stainless elbows for precise flow direction changes.

ASTM A403 Stainless Steel Pipe Fittings refers to the material of forged and rolled austenitic stainless fittings for pressure pipes. Common grades are WP304/L, WP316/L. They can be used into many fields as engineering industry, energy conversion plants etc.

ASTM A403 Standard specification covers the standard for wrought austenitic stainless steel fittings for pressure piping applications.

| Steel No. | Type | C | Si | S | P | Mn | Cr | Ni | Mo | Other | ób | ós | δ5 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WP304 | 0.08 | 1 | 0.03 | 0.045 | 2 | 18-20 | 8-11 | 515 | 205 | 28 | |||

| WP304H | 0.04-0.1 | 1 | 0.03 | 0.045 | 2 | 18-20 | 8-11 | 515 | 205 | 28 | |||

| WP304L | 0.035 | 1 | 0.03 | 0.045 | 2 | 18-20 | 8-13 | 485 | 170 | 28 | |||

| WP304LN | 0.03 | 0.75 | 0.03 | 0.045 | 2 | 18-20 | 8-10.5 | N2:0.1-0.16 | 515 | 205 | 28 | ||

| WP304N | 0.08 | 0.75 | 0.03 | 0.045 | 2 | 18-20 | 8-11 | N2:0.1-0.16 | 550 | 240 | 28 | ||

| WP309 | 0.15 | 1 | 0.03 | 0.045 | 2 | 22-24 | 12-15 | 515 | 205 | 28 | |||

| WP310 | 0.15 | 1.5 | 0.03 | 0.045 | 2 | 24-26 | 19-22 | 515 | 205 | 28 | |||

| WP316 | 0.08 | 1 | 0.03 | 0.045 | 2 | 16-18 | 10-14 | 2-3 | 515 | 205 | 28 | ||

| WP316H | 0.04-0.1 | 1 | 0.03 | 0.045 | 2 | 16-18 | 10-14 | 2-3 | 515 | 205 | 28 | ||

| WP316LN | 0.03 | 0.75 | 0.03 | 0.045 | 2 | 16-18 | 11-14 | 2-3 | N2:0.1-0.16 | 515 | 205 | 28 | |

| WP316L | 0.035 | 1 | 0.03 | 0.045 | 2 | 16-18 | 10-16 | 2-3 | 485 | 170 | 28 | ||

| WP316N | 0.08 | 0.75 | 0.03 | 0.045 | 2 | 16-18 | 11-14 | 2-3 | N2:0.1-0.16 | 550 | 240 | 28 | |

| WP317 | 0.08 | 1 | 0.03 | 0.045 | 2 | 18-20 | 11-15 | 3-4 | 515 | 205 | 28 | ||

| WP317L | 0.03 | 1 | 0.03 | 0.045 | 2 | 18-20 | 11-15 | 3-4 | 515 | 205 | 28 | ||

| WP321 | 0.08 | 1 | 0.03 | 0.045 | 2 | 17-20 | 9-13 | Ti:5C-0.7 | 515 | 205 | 28 | ||

| WP321H | 0.04-0.1 | 1 | 0.03 | 0.045 | 2 | 17-20 | 9-13 | Ti:4C-0.7 | 515 | 205 | 28 | ||

| WP347 | 0.08 | 1 | 0.03 | 0.045 | 2 | 17-20 | 9-13 | Nb+Ta:10C-1.1 | 515 | 205 | 28 | ||

| WP347H | 0.04-0.1 | 1 | 0.03 | 0.045 | 2 | 17-20 | 9-13 | Nb+Ta:8C-1 | 515 | 205 | 28 | ||

| WP348 | 0.08 | 1 | 0.03 | 0.045 | 2 | 17-20 | 9-13 | Ta:0.1 | 515 | 205 | 28 | ||

| WP348H | 0.04-0.1 | 1 | 0.03 | 0.045 | 2 | 17-20 | 9-13 | Ta:0.1 | 515 | 205 | 28 |

Notes:

For each reduction of 0.01% below the specified C maximum, an increase of 0.06% Mn above the specified maximum will be permitted, up to a maximum of 1.35%.

The sum of Cu, Ni, Cr, and Mo shall not exceed 1.00%.

The sum of Cr and Mo shall not exceed 0.32%.

The maximum carbon equivalent (C.E.) shall be 0.50, based on heat analysis and the formula C.E.=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15.

| Grade | UNS | Tensile Strength, min | Yield Strength,min | Elongation min % in 4D | |||

|---|---|---|---|---|---|---|---|

| ksi | MPa | ksi | MPa | Longit % | Trans% | ||

| ALL | ALL | 75 | 515 | 30 | 205 | 28 | 20 |

| 304L | S30403 | 70 | 485 | 25 | 170 | 28 | 20 |

| 316L | S31603 | 70 | 485 | 25 | 170 | 28 | 20 |

| 304N | S30451 | 80 | 550 | 35 | 240 | 28 | 20 |

| 316N | S31651 | 80 | 550 | 35 | 240 | 28 | 20 |

| S31726 | 80 | 550 | 35 | 240 | 28 | 20 | |

| XM-19 | S20910 | 100 | 690 | 55 | 380 | 28 | 20 |

| S31254 | 94-119 | 650-820 | 44 | 300 | 28 | 20 | |

| S34565 | 115 | 795 | 60 | 415 | 28 | 20 | |

| S33228 | 73 | 500 | 27 | 185 | 28 | 20 | |

Material Furnished to this specification shall conform to the requirements of specifications A960/A960M including any supplementary requirements that are indicates in the purchase order. Failure to company with the common requirements of Specification A960/A960M constitutes non-conformance with this specification . In case of conflict between this specification and Specification A960/A960M , this specification shall prevail.

Material Furnished to this specification shall conform to the requirements of specifications A960/A960M including any supplementary requirements that are indicates in the purchase order. Failure to company with the common requirements of Specification A960/A960M constitutes non-conformance with this specification. In case of conflict between this specification and Specification A960/A960M , this specification shall prevail.

The standard includes several grades of austenitic stainless steel alloys, and uses the WP or CR prefix to mark the grade of steel, depending on the applicable ASTM or MSS size and rated pressure standards. ASTM A403 is designed for forged steel pipe fittings, Cast pipe fittings are not suitable.

Stub ends are essential components used in various industrial applications, particularly in piping systems.

The use of stub ends has these two advantages:

Reduces the overall cost of the flanged joint Generally, the lap joint flange is of a lower grade than the material of the stub end and the pipework, thus saving the total weight of high-grade material used for the flanged joint.

Reduces the overall cost of the flanged joint

Generally, the lap joint flange is of a lower grade than the material of the stub end and the pipework, thus saving the total weight of high-grade material used for the flanged joint.

Example:

For an SS316 pipe, instead of using a full 316 welding neck flange, a combination of an SS316 stub end and a carbon steel lap joint flange would do the same exact job, but the total weight of SS316 material would be lower, and the cost as well.

Essentially, stub ends allow to minimize the weight of high-grade material in stainless, duplex, and nickel alloy piping, saving costs. Of course, the bigger the diameter and the class of the flanges, the higher the saving!

Commercial advantages are that the Stub End, will be wetted and it must be made of a grade of material that meets the process design and service conditions of the pipeline. However, the Lap Flange is un-wetted and it can be made of a lower grade of material as long as it meets the mechanical strength requirements of the piping systems.

The “loose” Flange concept of a Lap Joint, is very beneficial during field installation of piping systems. If two spools are to be mated up in the field, having one Flange that can be rotated is very advantageous when aligning the bolt holes, prior to the introduction of the Stub bolt and the accompanying nuts. The facility of easier orientation and alignment of bolt holes, is of particular use it there is a spool that has to be removed frequently, if positive isolation is a process requirement.

While stub ends offer numerous advantages in piping systems, it's essential to also consider their limitations. Being aware of these limitations helps engineers, designers, and operators make informed decisions when selecting fittings for specific applications. Let's explore some of the key limitations associated with stub ends:

Stub ends, particularly those used in lap joint flange connections, often have lower pressure ratings compared to fully welded or threaded alternatives. This limitation makes them unsuitable for high-pressure applications.

Stub ends are typically made from materials that can be easily formed and welded, such as stainless steel and carbon steel. However, they may not be compatible with certain materials like exotic alloys or non-metallic materials.

In applications where there is significant vibration, movement, or mechanical stress, stub ends may not provide the same level of reliability as fully welded connections. The slip-on design could potentially lead to loosening or disconnection.

Unlike fully welded joints, stub ends rely on the lap joint flange for connection strength. This means the joint's integrity is dependent on the quality of the flange and the fasteners used.

Due to the gapped design between the pipe end and the flange, there is a risk of leakage, especially when dealing with fluids or gases under pressure. The joint might require additional sealing measures to prevent leaks.

Certain materials used for stub ends may not withstand extremely high temperatures, limiting their application in industries where elevated temperatures are common.

Stub ends might limit axial pipe movement and thermal expansion compared to fully flexible joints. This could impact the system's ability to accommodate changes in temperature or pressure.

The effectiveness of stub ends relies on the quality of the lap joint flange and the proper installation of fasteners. Any issues with flange quality or installation can compromise the joint's integrity.

For applications where a secure and leak-proof connection is paramount, such as those involving hazardous or toxic substances, fully welded joints may be preferred over stub ends.

Stub ends can be harder to inspect and maintain compared to fully welded joints, as visual assessment of the joint's condition may be limited due to the slip-on design.

Stub ends, particularly those made from certain materials, may not be suitable for use in environments with severe corrosion or aggressive chemical exposure.

In conclusion, while stub ends offer various advantages, they also come with specific limitations that need to be carefully considered during the selection and design of piping systems. Engineers and operators should evaluate the specific requirements of each application and assess whether the benefits of using stub ends outweigh their limitations. By making informed decisions, industries can ensure safe, reliable, and efficient piping networks that meet the demands of their operational environments.

A stud end and a lap joint flange can be used together as an alternative way to make a flanged connection than welding neck flanges.

Using a stud end and a lap joint flange provides an alternative method for creating a flanged connection, different from welding neck flanges.

The components involved are:

This approach offers flexibility and ease of assembly, making it a valuable alternative to traditional welding neck flanges.

Stub end is widely used in the petroleum, chemical, power, gas, metallurgy, shipbuilding and construction industries. It is made from high quality raw materials, and available in a variety of sizes and designs.

The use of stub ends has these two advantages:

Stub end is widely used in the petroleum, chemical, power, gas, metallurgy, shipbuilding and construction industries. It is made from high quality raw materials, and available in a variety of sizes and designs. The combination of stub ends and backing flanges is an alternative way to join pipes compared to the use of standard flanges.

90° Lateral Wye R500 DN150 Export to Pilipinas with lap-joint flanges

This solution is used in these typical scenarios:

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.