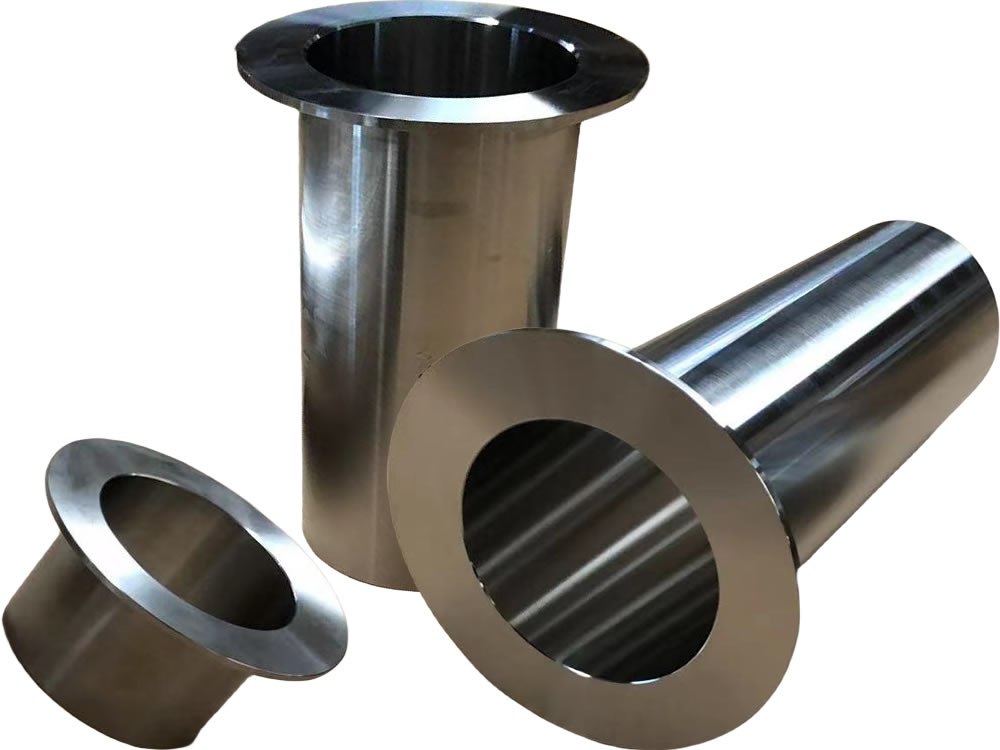

Pipe Collar

High-quality Pipe Collars for various piping systems.

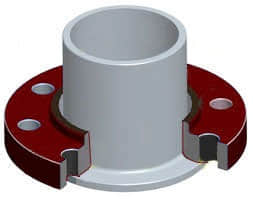

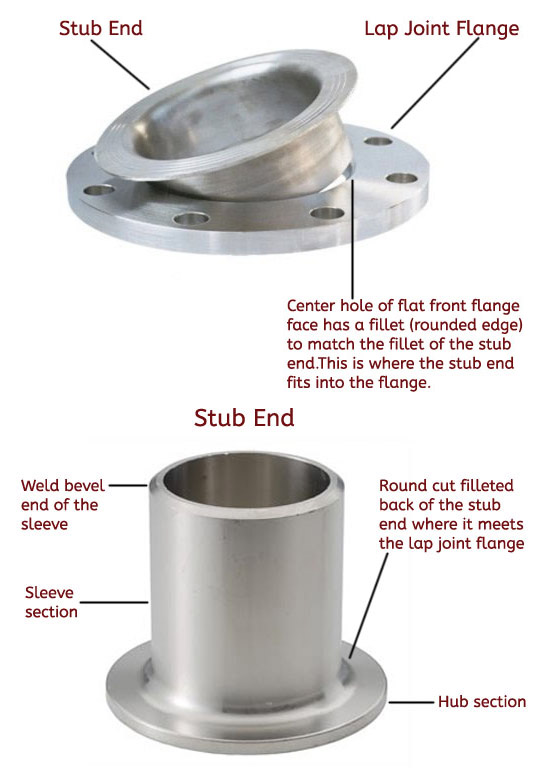

A lap joint stub end is a type of pipe fitting that is used in conjunction with a lap joint flange.

It consists of a short piece of pipe with one end machined to be butt-welded to the pipe, and the other end is designed to slide into the lap joint flange.

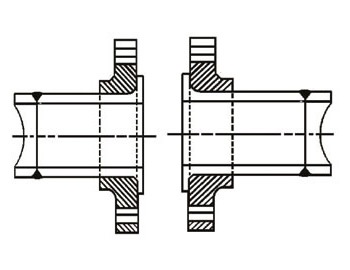

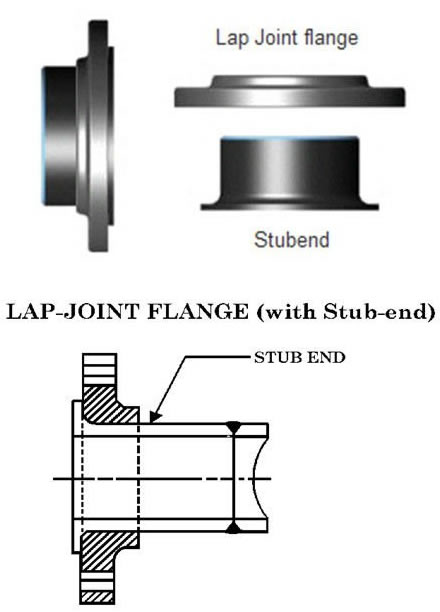

A lap-joint flange is a two-component assembly, with a stub end that has a lap-joint ring flange placed over it. The stub end is then butt welded to the pipe, and the flange ring can be rotated to align with the mating flange. This type of flange connection is particularly useful for large or hard-to-adjust flanges.

Lap joint stub end is a fitting that is used replace welded flanges when the support of a rotating back up flange is required. And It can be supplied in standard and non-standard ANSI dimension that is used for connecting pipes of different diameter.

The purpose of a lap joint stub end is to provide a means of disconnecting and reconnecting a flanged piping system. It allows for easy alignment and adjustment of the flange without having to cut or alter the existing pipe. The stub end is typically welded to the pipe, while the lap joint flange can be rotated or adjusted as needed.

Lap joint stub ends exhibit essential qualities, including:

When selecting a lap joint stub end, it is important to consider factors such as pipe size, material compatibility, and pressure rating. The dimensions and specifications for lap joint stub ends can be found in standards such as ASME B16.9.

Remember to follow industry standards and guidelines for proper installation and ensure that the lap joint stub end and flange are compatible with the specific application requirements.

Lap-joint flanges are most commonly available in carbon steel and low temperature carbon steel, because it is a lower cost than the Stub End that will be wetted by the service and it must be of a suitable grade of steel. If orientation and alignment of bolt holes is the only issue, then for standardization, then the Stub End and the Lap Joint Flange can be of the same material.

The most common material grade for stub end is the ASTM A403 / ASME SA403 (stainless steel stub ends). With reference to EU materials, the most common grades are DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404.

The MSS standard is the regular length stub end and the most commonly used in the flange industry.

Lap joint stub ends play a crucial role in various industries, offering a practical and cost-effective solution for pipe connections that require frequent disassembly.

Q: Can lap joint stub ends be used with any type of flange?

A: Lap joint stub ends are designed to be used specifically with lap joint flanges, ensuring compatibility and ease of disassembly.

Q: Are lap joint stub ends reusable after disassembly?

A: Yes, lap joint stub ends can be reused if they remain in good condition after disassembly, making them a cost-effective choice for pipe connections.

Q: Are lap joint stub ends suitable for high-pressure applications?

A: Lap joint stub ends are generally used in low to medium-pressure applications. For high-pressure systems, other types of pipe fittings may be more appropriate.

Q: Can lap joint stub ends be used with pipes of different materials?

A: Yes, lap joint stub ends can be used with pipes made from various materials, providing versatility in different piping systems.

Q: Do lap joint stub ends require any special tools for assembly and disassembly?

A: Lap joint stub ends can be easily assembled and disassembled using basic hand tools, making them user-friendly and convenient for maintenance tasks.

In piping systems, a stub end is a crucial component used for connecting pipes of different materials and sizes. It provides a convenient and cost-effective solution for achieving a leak-free joint without the need for welding. In this article, we will explore the geometry, types, and applications of stub ends, shedding light on their significance in various industries and projects.

| N.D. | Out diamater | Hight(F) | Stub end O.D.(G) | Beveld radio(R) | ||||

|---|---|---|---|---|---|---|---|---|

| NPS | DN | OD | Mss | ANSI | Nominal&max | Nominal&min | A Max | B Max |

| 1/2 | 15 | 21.3 | 50.8 | 76.2 | 35 | 34 | 3 | 0.8 |

| 3/4 | 20 | 26.7 | 50.8 | 76.2 | 43 | 42 | 3 | 0.8 |

| 1 | 25 | 33.4 | 50.8 | 101.6 | 51 | 50 | 3 | 0.8 |

| 1 1/4 | 32 | 42.4 | 50.8 | 101.6 | 64 | 63 | 4.8 | 0.8 |

| 1 1/2 | 40 | 48.3 | 50.8 | 101.6 | 73 | 72 | 6.4 | 0.8 |

| 2 | 50 | 60.3 | 63.5 | 152.4 | 92 | 91 | 7.9 | 0.8 |

| 2 1/2 | 65 | 73 | 63.5 | 152.4 | 105 | 104 | 7.9 | 0.8 |

| 3 | 80 | 88.9 | 63.5 | 152.4 | 127 | 126 | 9.6 | 0.8 |

| 3 1/2 | 90 | 101.6 | 76.2 | 152.4 | 140 | 139 | 9.6 | 0.8 |

| 4 | 100 | 114.3 | 76.2 | 152.4 | 157 | 156 | 11.2 | 0.8 |

| 5 | 125 | 141.3 | 76.2 | 203.2 | 186 | 185 | 11.2 | 1.6 |

| 6 | 150 | 168.3 | 88.9 | 203.2 | 216 | 215 | 12.7 | 1.6 |

| 8 | 200 | 219.1 | 101.6 | 203.2 | 270 | 269 | 12.7 | 1.6 |

| 10 | 250 | 273.1 | 127 | 254 | 324 | 322 | 12.7 | 1.6 |

| 12 | 300 | 323.9 | 152.4 | 254 | 381 | 379 | 12.7 | 1.6 |

| 14 | 350 | 355.6 | 152.4 | 304.8 | 413 | 411 | 12.7 | 1.6 |

| 16 | 400 | 406.4 | 152.4 | 304.8 | 470 | 468 | 12.7 | 1.6 |

| 18 | 450 | 457.2 | 152.4 | 304.8 | 533 | 531 | 12.7 | 1.6 |

| 20 | 500 | 508 | 152.4 | 304.8 | 584 | 582 | 12.7 | 1.6 |

| 22 | 550 | 559 | 152.4 | 304.8 | 641 | 639 | 12.7 | 1.6 |

| 24 | 600 | 610 | 152.4 | 304.8 | 692 | 690 | 12.7 | 1.6 |

The Stub End, which essentially a short length of pipe, which has one end that is flared outwards and the other end prepared to be welded to pipe of the same Nominal Pipe Size (NPS), material and of a similar wall thickness. The Lap Joint Flange, which is a ring backing Flange and it is very similar in geometry to the Slip-on Flange.

Stub ends are mechanical joints that comprises of two components.

This type of flanged connection was also referred to as “Van Stone” or “Vanstone flare laps”, however this is an historic terminology and very rarely used technically or commercially.

For packing of carbon steel flanges with painting,we would use the bubble wrap to protect the painting.For flanges without painting or oiled with long-term shipment,we would suggest client to use the anti-tarnish paper and plastic bag to prevent the rust.

Stub ends and lap joint flanges can be assembled following this process:

It can also be mated to a fabricated plate Flange with compatible, bolting dimensions.

Duplex Stub End and a Duplex Lap Joint, you could have Duplex Stub End and Carbon Steel Lap Flange.

Or you could have Stainless Stub End and Carbon Steel Lap Flange. There are other bimetallic combinations that result in a flange assembly that is commercially cheaper.

During recent years the price differential between Duplex/Stainless Steel and Carbon Steel has narrowed and this practice on large Projects has become less common, however a cost difference always exists (the higher the NPS and the length of the pipeline / piping system, the higher the saving). On the other hand, the warehousing cost of one single component, i.e. a Weld Neck Flange, requires less shelf space than the cost of warehousing a Lap Joint and a Stub End. End Users and Contractors shall determine the actual convenience of using stub ends, considering all these factors and generally the commercial advantage is still valid and it may suit certain situation, especially in “brownfield” modifications.

The following information shall be provided to order a stub end:

Stub ends can be ordered with different ends finishing:

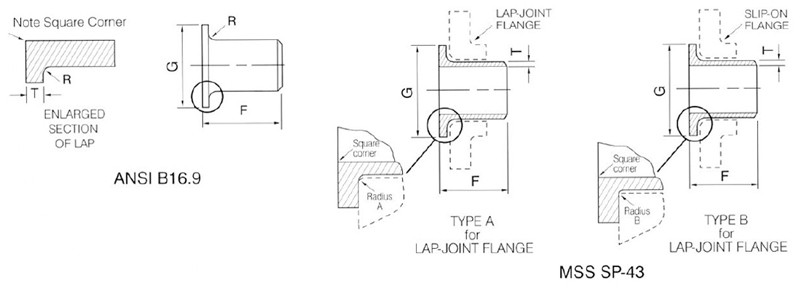

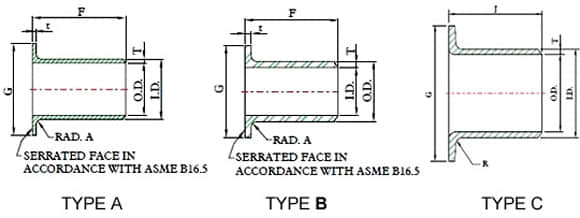

Stub end are offered in three different ways, type A, B and C. Type A and B stub end are similar to forged fittings, such as elbows and tees, and type C stub end are made in customized sizes.

Stub ends are manufactured in three different types and two standard length.

Type “A”: this type is produced and machined to fit lap joint flanges.The mating surfaces of the stub end and the lap joint flange have a matching profile and surface. The lap thickness of type A stub ends is > = the minimum wall thickness of the connected pipe. The outside the stub end and the lap joint flange have a matching profile and surface. The lap thickness of type A stub ends is > = the minimum wall thickness of the connected pipe. The outside corner of type A has a radius to accommodate the lap join flange, whereas the inside corner is squared.

Type “B”: this type of stub ends is suited for standard slip-on flanges acting as lap-joint flanges. The lap thickness of type B stub ends is >= the minimum WT of the connecting pipe. The lap of these type of stub ends has generally a serrated face. To ensure tight joints, chamfers on the ID side of the flange are required.

Type “C”: this last type can be used both with lap joint and slip-on backing flanges and are fabricated out of pipes. The lap of C-type stub ends is flared over and the lap thickness is 75% of the connecting pipe WT. Type C has a short fillet outer radius able to host any back up flange.

Type “CS”: this type is similar to “C” with the difference that the lap face has concentric serrations machined during the manufacturing process.

There are two main types of stub ends commonly used in piping systems:

Both long pattern and short pattern stub ends are available in various materials such as stainless steel, carbon steel, alloy steel, and others, making them suitable for different industrial applications. They provide a cost-effective and reliable solution for connecting pipes to flanges in piping systems.

Dimensions and manufacturing tolerances are covered in ASME B16.9 – Butt Weld Fittings and MSS-SP-43 (JIS B2312, JIS B2313 may also apply).

Stub End come in three standard lengths, MSS SP43 or ANSI B16.9 short and long pattern. Short pattern stub ends are mostly used for flanges from class 300 to class 600 and above. Besides these standard types, End-Users and contractors can require stub ends with non-standard lengths to suit specific project’s requirement. This will of course come at an additional cost.

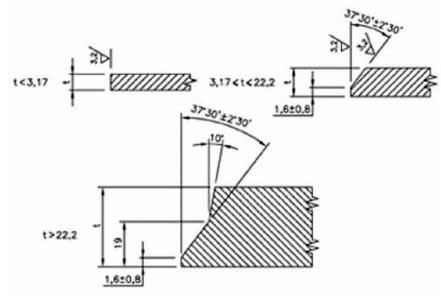

ASME B16.25 END WELDING BEVEL as right

The following types of ends may be ordered:

Beveled Ends (generally ASME B16.25)

Squared Ends

Flanged Ends

Victaulic Grooves

Threaded Ends (Male Only)

Stub ends are essential components used in various industrial applications, particularly in piping systems.

The use of stub ends has these two advantages:

Reduces the overall cost of the flanged joint Generally, the lap joint flange is of a lower grade than the material of the stub end and the pipework, thus saving the total weight of high-grade material used for the flanged joint.

Reduces the overall cost of the flanged joint

Generally, the lap joint flange is of a lower grade than the material of the stub end and the pipework, thus saving the total weight of high-grade material used for the flanged joint.

Example:

For an SS316 pipe, instead of using a full 316 welding neck flange, a combination of an SS316 stub end and a carbon steel lap joint flange would do the same exact job, but the total weight of SS316 material would be lower, and the cost as well.

Essentially, stub ends allow to minimize the weight of high-grade material in stainless, duplex, and nickel alloy piping, saving costs. Of course, the bigger the diameter and the class of the flanges, the higher the saving!

Commercial advantages are that the Stub End, will be wetted and it must be made of a grade of material that meets the process design and service conditions of the pipeline. However, the Lap Flange is un-wetted and it can be made of a lower grade of material as long as it meets the mechanical strength requirements of the piping systems.

The “loose” Flange concept of a Lap Joint, is very beneficial during field installation of piping systems. If two spools are to be mated up in the field, having one Flange that can be rotated is very advantageous when aligning the bolt holes, prior to the introduction of the Stub bolt and the accompanying nuts. The facility of easier orientation and alignment of bolt holes, is of particular use it there is a spool that has to be removed frequently, if positive isolation is a process requirement.

While stub ends offer numerous advantages in piping systems, it's essential to also consider their limitations. Being aware of these limitations helps engineers, designers, and operators make informed decisions when selecting fittings for specific applications. Let's explore some of the key limitations associated with stub ends:

Stub ends, particularly those used in lap joint flange connections, often have lower pressure ratings compared to fully welded or threaded alternatives. This limitation makes them unsuitable for high-pressure applications.

Stub ends are typically made from materials that can be easily formed and welded, such as stainless steel and carbon steel. However, they may not be compatible with certain materials like exotic alloys or non-metallic materials.

In applications where there is significant vibration, movement, or mechanical stress, stub ends may not provide the same level of reliability as fully welded connections. The slip-on design could potentially lead to loosening or disconnection.

Unlike fully welded joints, stub ends rely on the lap joint flange for connection strength. This means the joint's integrity is dependent on the quality of the flange and the fasteners used.

Due to the gapped design between the pipe end and the flange, there is a risk of leakage, especially when dealing with fluids or gases under pressure. The joint might require additional sealing measures to prevent leaks.

Certain materials used for stub ends may not withstand extremely high temperatures, limiting their application in industries where elevated temperatures are common.

Stub ends might limit axial pipe movement and thermal expansion compared to fully flexible joints. This could impact the system's ability to accommodate changes in temperature or pressure.

The effectiveness of stub ends relies on the quality of the lap joint flange and the proper installation of fasteners. Any issues with flange quality or installation can compromise the joint's integrity.

For applications where a secure and leak-proof connection is paramount, such as those involving hazardous or toxic substances, fully welded joints may be preferred over stub ends.

Stub ends can be harder to inspect and maintain compared to fully welded joints, as visual assessment of the joint's condition may be limited due to the slip-on design.

Stub ends, particularly those made from certain materials, may not be suitable for use in environments with severe corrosion or aggressive chemical exposure.

In conclusion, while stub ends offer various advantages, they also come with specific limitations that need to be carefully considered during the selection and design of piping systems. Engineers and operators should evaluate the specific requirements of each application and assess whether the benefits of using stub ends outweigh their limitations. By making informed decisions, industries can ensure safe, reliable, and efficient piping networks that meet the demands of their operational environments.

A stud end and a lap joint flange can be used together as an alternative way to make a flanged connection than welding neck flanges.

Using a stud end and a lap joint flange provides an alternative method for creating a flanged connection, different from welding neck flanges.

The components involved are:

This approach offers flexibility and ease of assembly, making it a valuable alternative to traditional welding neck flanges.

Stub end is widely used in the petroleum, chemical, power, gas, metallurgy, shipbuilding and construction industries. It is made from high quality raw materials, and available in a variety of sizes and designs.

The use of stub ends has these two advantages:

Stub end is widely used in the petroleum, chemical, power, gas, metallurgy, shipbuilding and construction industries. It is made from high quality raw materials, and available in a variety of sizes and designs. The combination of stub ends and backing flanges is an alternative way to join pipes compared to the use of standard flanges.

90° Lateral Wye R500 DN150 Export to Pilipinas with lap-joint flanges

This solution is used in these typical scenarios: