5D Bend Pipe

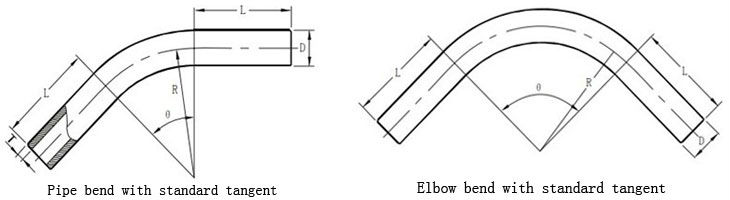

The radius of a 5D pipe bend is actually what is 5 times the nominal diameter.

Carbon Steel Pipe Fittings Elbow could be a most common sort of CS fitting utilized to connect pipe or tubing to permit a alter of direction, more often than not a 90° or 45° angle, though 22.5 Degree Elbow Carbon Steel is additionally utilized in a piping framework.

Carbon Steel Pipe Fittings Elbow could be a most common sort of CS fitting utilized to connect pipe or tubing to permit a alter of direction, more often than not a 90° or 45° angle, though 22.5 Degree Elbow Carbon Steel is additionally utilized in a piping framework. Carbon steel elbows are metal fittings that change the direction of the pipe on the carbon steel pipe. Connections are threaded and welded. Divided by angle, there are 45 ° and 90 ° 180 ° the three most commonly used, in addition to other engineering needs also include 60 ° and other abnormal angle elbow. Elbow materials are cast iron, stainless steel, alloy steel, malleable iron, carbon steel, non-ferrous metals and plastics. The connections to the tube are: direct welding (the most common method) flange connection, hot melt connection, electrofusion connection, screw connection and socket connection. According to the production process can be divided into: welding elbow, stamping elbow, pushing elbow, casting elbow and so on.Carbon steel elbow is a kind of carbon steel pipe fittings.

| Material | Steel pipe | Elbow fitting |

|---|---|---|

| Carbon Steel | A106 Gr A | A234 Gr WPA |

| A106 Gr B | A234 Gr WPB | |

| A106 Gr C | A234 Gr WPC | |

| Carbon steel, alloy, high-temp | A335 Gr P1 | A234 Gr WP1 |

| A335 Gr P11 | A234 Gr WP11 | |

| A335 Gr P12 | A234 Gr WP12 | |

| A335 Gr P22 | A234 Gr WP22 | |

| A335 Gr P5 | A234 Gr WP5 | |

| A335 Gr P9 | A234 Gr WP9 | |

| Carbon steel alloy low-temp | A333 Gr 6 | A420 Gr WPL6 |

| A333 Gr 3 | A420 Gr WPL3 |

ASTM/ ASME A234 WPB / A860 – MSS-SP-75 WPHY 42 / 46 / 52 / 56 / 60 / 65 / 70 Elbow

Low temperature Steel: A420 WPL3 / A420 WPL6 Elbow

Size range: 1/2 to 56 inches (DN 15 to DN 1,400mm), 22.5 Deg, 45 Deg, 90 Deg, 180 Deg

Carbon steel elbow is first divided into its radius of curvature, which can be divided into long radius elbows and short radius elbows. The long-radius elbow refers to its radius of curvature equal to 1.5 times the outer diameter of the tube, ie R = 1.5D. A short-radius elbow means that its radius of curvature is equal to the outer diameter of the tube, ie R = 1.0D. (D is the diameter of the elbow, and R is the radius of curvature. D can also be expressed in terms of folds.) If there are 17 levels depending on the pressure rating, the same standards as in the U.S. tube are: Sch5s, Sch10s, Sch10 , Sch20, Sch30, Sch40s, STD, Sch40, Sch60, Sch80s, XS; Sch80, Sch100, Sch120, Sch140, Sch160, XXS, the most commonly used are STD and XS. According to the angle of the elbow, there are 45° elbows, 90° elbows and 180° elbows.

Radius of curvature is the curvature of a curve. The curvature of a plane curve is defined as the rotation rate of the tangent angle of a point on the curve to the length of the arc. It is defined by differentiation and it shows the degree of the curve deviating from the line. The reciprocal of curvature is the radius of curvature. The radius of curvature is mainly used to describe the extent of curvature variation of a point on a curve.

It is required that the radius of curvature should be controlled. For example, if the radius is 1.5D, then the radius of curvature must be within the required tolerance range. Because most of these pipe fittings are used for welding, in order to improve the quality of welding, the end will be turned into the groove and it will keep the certain angle and edge. This requirement is quite strict, and the thickness of the edge, the angle as well as the deviation range are all defined. There are more requirements on the physical dimension of long radius elbows than those on the pipe fittings. The surface quality and mechanical properties of the elbow are almost the same as the pipe’s. To facilitate welding, the long radius elbow should be made of the same kind material of the pipe to be connected.

ASTM/ ASME A234 WPB / A860 – MSS-SP-75 WPHY 42 / 46 / 52 / 56 / 60 / 65 / 70 Elbow

Low temperature Steel: A420 WPL3 / A420 WPL6 Elbow

Size range: 1/2 to 56 inches (DN 15 to DN 1,400mm), 22.5 Deg, 45 Deg, 90 Deg, 180 Deg

Carbon steel elbow is first divided into its radius of curvature, which can be divided into long radius elbows and short radius elbows. The long-radius elbow refers to its radius of curvature equal to 1.5 times the outer diameter of the tube, ie R = 1.5D. A short-radius elbow means that its radius of curvature is equal to the outer diameter of the tube, ie R = 1.0D. (D is the diameter of the elbow, and R is the radius of curvature. D can also be expressed in terms of folds.) If there are 17 levels depending on the pressure rating, the same standards as in the U.S. tube are: Sch5s, Sch10s, Sch10 , Sch20, Sch30, Sch40s, STD, Sch40, Sch60, Sch80s, XS; Sch80, Sch100, Sch120, Sch140, Sch160, XXS, the most commonly used are STD and XS. According to the angle of the elbow, there are 45° elbows, 90° elbows and 180° elbows.

Radius of curvature is the curvature of a curve. The curvature of a plane curve is defined as the rotation rate of the tangent angle of a point on the curve to the length of the arc. It is defined by differentiation and it shows the degree of the curve deviating from the line. The reciprocal of curvature is the radius of curvature. The radius of curvature is mainly used to describe the extent of curvature variation of a point on a curve.

It is required that the radius of curvature should be controlled. For example, if the radius is 1.5D, then the radius of curvature must be within the required tolerance range. Because most of these pipe fittings are used for welding, in order to improve the quality of welding, the end will be turned into the groove and it will keep the certain angle and edge. This requirement is quite strict, and the thickness of the edge, the angle as well as the deviation range are all defined. There are more requirements on the physical dimension of long radius elbows than those on the pipe fittings. The surface quality and mechanical properties of the elbow are almost the same as the pipe’s. To facilitate welding, the long radius elbow should be made of the same kind material of the pipe to be connected.

Steel pipe elbow (sometimes also refereed as bends) is a key part in a pressure piping system used to change the fluid flow direction. It is used to connect two pipes with same or different nominal diameters, and to make the pipe and thus the fluid direction turn to a certain direction of 45 degree or 90 degree.

Steel pipe elbows can be classified through following various parameters,

According to fluid flow direction of the pipes, elbows can be divided into different degrees, such as 45 degree, 90 degree, 180 degree, which are most common elbows. Also there are 60 degree and 120 degree elbows for some special pipelines. This degree is just an representation of the angle by which the fluid flow is going to change after flowing through the said elbow.

The welded elbows 5D (radius two and half diameter) are used to divert the flow of the pipes. 5D-welded elbows are useful to transport granular materials and powders. In France this type of elbow is also called coude grand rayon.

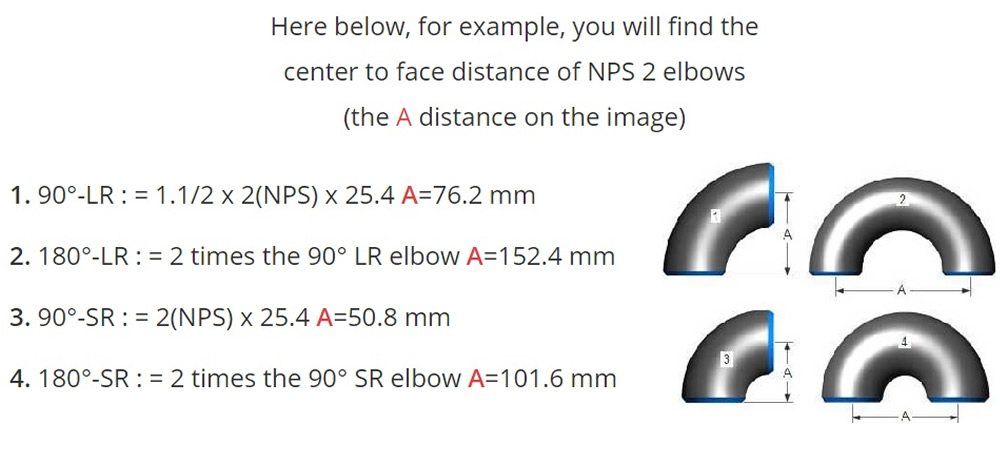

Elbows are split into two groups which define the distance over which the flowing fluid change direction; the center line of one end to the opposite face. This is known as the “Center to Face” distance and is equivalent to the radius through which the elbow is bent.

If the radius is the same as pipe diameter (Center-to-Face dimension of 1.0 X diameter ), it called Short Radius Elbow (SR elbow) used normally for low pressure and low speed pipelines or in tight areas where clearance is the main issue. If the radius is larger than pipe diameter (Center-to-Face dimension of 1.5 X diameter) then we call it a Long Radius Elbow (LR Elbow) used for high pressure and high flow rate pipelines.

The elbow is divided into its radius of curvature and can be divided into a long radius elbow and a short radius elbow. The long radius elbow refers to the outer diameter of the tube whose radius of curvature is equal to 1.5 times, that is, R = 1.5D. A short radius elbow means that its radius of curvature is equal to the outer diameter of the tube, ie R = D. Where D is the diameter of the elbow and R is the radius of curvature. Normal use of the length of the radius Sometimes to reduce the loss of resistance or elbow wear, the elbow with a larger bending radius will be used (in fact, it is not called elbow); when there is a limit on the installation position, a short radius elbow will be used.

There are two types of pipe sizes for process installation, namely pipe outer diameter and nominal size. D, DN, refers to the nominal size of the pipe. It does not represent the inner diameter of the pipe or the outer diameter of the pipe. It is a nominal size designed and used. The elbow is the elbow, and the manufacturing method is divided into the push elbow, the extrusion elbow and the welded miter elbow. The structure length is 1.0D, 1.5D, 2.0D.

At present, there are two kinds of norms implemented in this area in China: metric and imperial. For example: 1.5D steel seamless elbow, DN100 outer diameter ¢108 and ¢114.3, actual structural length L152, DN200 outer diameter ¢219 and ¢216.3, actual structural length L302. In use, long radius elbow (R = 15DN): in general, should be preferred; short radius elbow (R = 1.0DN): mostly used in applications where size is limited. Its high working pressure should not exceed 0.8 times of the long radius elbow of the same specification.

Elbow (R=nDN): used to moderate the scouring and kinetic energy of the media at the bend, available to R=3DN, 6DN, 10DN, 20DN. According to different manufacturing methods, it is divided into push elbow, extrusion elbow and welded miter elbow.

Pushing elbows and extrusion elbows: Commonly used for welding mitered elbows on medium and small-sized pipes with strict media conditions: It is often used on large-sized pipes with moderate media conditions, and the bending radius is not to be less than its nominal diameter. 1.5 times. When the miter angle of the miter elbow is greater than 450, it should not be used on highly toxic, flammable medium pipes, or on pipes subjected to mechanical vibration, pressure pulsation and alternating load due to temperature changes.

So how do we buy qualified elbows? Detecting the back arc of the elbow: Seamless elbow detection of the thickness of the back arc is an important task. Many large pipe elbow manufacturers or strict engineering inspection of the back arc is a must. It is related to the safety and stability of the pipeline operation.

Everyone knows that both the seamless steel pipe and the seamless elbow are under pressure, that is, the pressure is very large when running. Under normal circumstances, the safety factor of the thickness of the seamless elbow designed and installed is about six times. For example, the 219*8 seamless elbow, the pipeline medium is ordinary water, the temperature is usually not higher than one hundred degrees Celsius, and the pressure required to blast such a seamless elbow is about 300 kg, that is to say, The pressure inside the pipeline needs to reach PN30, and the seamless elbow will be blasted, and the operating pressure of this elbow is probably about it. It is estimated that the maximum will not exceed PN6.4, which is generally around PN4.0, of course. With the corrosion of the pipeline, the seamless elbow will also be corroded to varying degrees. In order to ensure its safe operation, the necessity of overhaul is also great.

The current process of making seamless elbows will lead to the phenomenon of back arc thinning. Under normal circumstances, the wall thickness of the mouth will be about two millimeters thinner than the back arc. The common thickness and pressure are not thinner even if the back arc is thinned. There will be too many safety hazards, because the elbow has not been replaced until the elbow has a dangerous accident. But as a rigorous project, what is not the same, and the medium inside the pipeline is also responsible, not just water. There may be oil or other impurities, the temperature is high and the pressure is high, and the thickness of the back arc as the weak place determines the life of the seamless elbow. Therefore, the importance of detecting the back arc is naturally great. With the thickness gauge, read the thickness of a point at the elbow directly.

You will often hear SR45 elbow or LR45 elbow. The 45 or 90 refers to the angle of the bend for buttweld fitting to change the direction of flow. A long radius elbow (LR 90 Elbow or LR 45 elbow) will have a pipe bend that will be 1.5 times the size of the pipe. So, a 6 inch LR 90 has bending radius that is 1.5 x nominal pipe size. A short radius elbow (SR45 or SR90) has a pipe bend that is equal to the size of the fitting, so a 6” SR 45 has a bending radius that is 6” nominal pipe size.

First, the terms 3R or 3D are used synonymously. A 3R butt weld elbow has a bending radius that is 3 times the nominal pipe size. A 3R elbow is smoother than SR or LR fitting.

As per the connection with pipe, elbows could be classified as Butt Welded Elbow, Socket Welded Elbow and Threaded Elbow.

Butt Welded Elbow

Butt weld elbow is a steel elbow formed by hot pressing or forging. Its connection form is to directly weld the elbow and steel pipe. Butt welded elbows have beveled ends to allow for ease of welding. This bevel allows for full penetration weld in most of the cases. Butt welded elbows are mainly used for elbow with higher pressure and temperature.

Socket Welded Elbow<

Socket weld elbow is also welded to the pipe and fittings end. Unlike the butt weld elbow, the socket weld elbow has a trapezoidal area at the end. We can insert pipe end into this area (the diameter of SW elbow is matched with the outer diameter of pipe), then do welding work to connect them together. Therefore, the actual diameter of SW elbow end is greater than the elbow diameter.

Threaded Elbow

The shape of threaded elbow is similar to the SW elbow, except that the inner surface of the trapezoidal area has been machined into thread. It is easier to install and remove, good for pipeline repair and maintenance.

Stainless Steel Elbow : ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

Carbon Steel Elbow : ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Low Temperature Carbon Steel Elbow : ASTM A420 WPL3, A420 WPL6

Alloy Steel Elbow : ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

Duplex Steel Elbow : ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Werkstoff No. 1.4462

Nickel Alloy Elbow : ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

In addition to the above defined elbows there are few more types of elbows which are not used on regular basis. Few of them has been defined below.

A reducing elbow is a type of fitting which is used to join two pipes of different sizes. The reducing elbow is so called because it looks like a reducing piece and elbow combined into one. The reducing elbow eliminates one pipe fitting (reducer) and reduces the welding by more than one-third. Also, the gradual reduction in diameter throughout the arc of the reducing elbow provides lower resistance to flow and reduces the effect of stream turbulence and potential internal erosion. These features prevent sizable pressure drops in the line.

For many suppliers it is a non standard item resulting into high price with a long delivery time. The use of a “normal” elbow with a separate reducer is an option if the situation allows.

Male pipe elbows and female pipe elbows are popular tube fittings which provide an fluid flow directional change of a tubing run. While a male pipe elbow is used to connect fractional tube to female tapered pipe thread, a female elbow is used to connect fractional tube to male NPT thread. These types of tube fittings like male elbows and female elbows have been specifically designed for use on instrumentation, process and control systems and equipment employed in chemical, petroleum, fluid power, electronic and pulp and paper plants.

The weakest point on an elbow is the inside radius. ASME B16.9 only standardizes the center to face dimensions and some “squareness” dimensional tolerances. The wall thickness at the weld line location even is standardized, but not through the rest of an elbow. The standard states that the minimum tolerance will be within 12.5% of the minimum ordered wall thickness of the pipe. A maximum tolerance is specified only at the ends of the fitting. Many providers of butt weld elbows provide one schedule greater thickness so that sufficient wall thickness, after forming, remains.

Pipe elbow fittings is a very important pipe fitting. When we talk about a pipe elbow, it means a length of pipe with a sharp bend in it. Pipe elbows are fitting accessories which are used widely in various industrial sectors in pipe fitting. A pipe elbow is frequently used in pressurized applications and are available in various shapes and sizes for use in different applications. A pipe elbow is a fitting installed between two lengths of pipe or tube allowing a change of direction, usually in the 90° or 45° direction.

Certain factors are to be considered for the proper purchase of pipe elbows. These factors are:

Everyone knows that both the pipeline and the seamless elbow are under pressure, that is, the pressure is very large when running. Under normal circumstances, the safety factor of the thickness of the seamless elbow designed and installed is about six times. For example, the 219*8 seamless elbow, the pipeline medium is ordinary water, the temperature is usually not higher than one hundred degrees Celsius, and the pressure required to blast such a seamless elbow is about 300 kg, that is, The pressure inside the pipeline needs to reach PN30, and the seamless elbow will be blasted, and the operating pressure of this elbow is probably about it. It is estimated that the maximum will not exceed PN6.4, which is generally around PN4.0, of course. With the corrosion of the pipeline, the seamless elbow will also be corroded to varying degrees. In order to ensure its safe operation, the necessity of overhaul is great.

The current process of making seamless elbows will lead to the phenomenon of back arc thinning. Under normal circumstances, the wall thickness of the mouth will be about two millimeters thinner than the back arc. The common thickness and pressure will not be thin even if the back arc is thinned. There are too many safety hazards, because the elbow has not been replaced until the elbow has a dangerous accident. But as a rigorous project, what is not the same, and the medium inside the pipeline is also responsible, not just water. There may be oil or other impurities, the temperature is high and the pressure is high, and the thickness of the back arc as the weak place determines the life of the seamless elbow. Therefore, the importance of detecting the back arc is naturally great. With a thickness gauge, read the thickness of a point at the elbow directly.

Detect the inner and outer diameters of the elbow: For example, the outer diameter dimension D of the elbow is detected: the data of the upper limit and the lower limit are referenced, and the actually measured outer diameter of the product is qualified between the upper and lower limits, and the unqualified product is outside the upper or lower limit range.

Detect the wall thickness of the elbow: use the thickness gauge to directly read the thickness of the thinnest part of the elbow.

Detect the center height of the elbow: first measure the length of the outer circle of the elbow. Using this length value /1.57, the value obtained by subtracting half of the diameter of the elbow is the center height of the elbow.

Detecting the weight of the elbow: The elbow is made of steel pipe. We only know the weight of the elbow when the elbow is cut, and the size of the elbow and the back arc of the elbow. The dimensions are basically the same. Let’s calculate the length of the back arc of the elbow: the diameter of the elbow is D, the radius of curvature is 1.5D, and the length of the back arc of the elbow is (1.5+0.5)*D*2*3.14/4 Simplification we can get, 1.5 times elbow back arc length L = D * 3.14. This is only an estimate. The value of the Chinese standard is slightly smaller than this value. After the length of the back arc is L, the weight of the steel pipe is calculated by the calculation formula of the steel pipe: (Da)*a*0.02466*L/1000, ( a is the wall thickness of the elbow), the unit of this weight is KG, so we can get the weight of the carbon steel elbow. If it is a stainless steel elbow, just replace 0.02466 with 0.02491. The calculated theoretical weight is then compared to the actual weight.

Radiographic inspection of elbows: Radiographic inspection detects volumetric defects of elbows, such as pores, slag inclusions, shrinkage cavities, and looseness.

The weakest point on an elbow is the inside radius. ASME B16.9 only standardizes the center to face dimensions and some "squareness" dimensional tolerances. The wall thickness at the weld line location even is standardized, but not through the rest of an elbow. The standard states that the minimum tolerance will be within 12.5% of the minimum ordered wall thickness of the pipe. A maximum tolerance is specified only at the ends of the fitting.

Many providers of buttweld elbows (and tees) provide one schedule greater thickness so that sufficient wall thickness, after forming, remains.

Along with build quality, the longevity and reliability of steel pipe elbows are highly dependent on the type and quality of the coating used. However, applying coatings to pipe elbows is not just about preventing corrosion, but can affect the evenness of flow through the pipe and the need to prevent contamination of pipe contents ((e.g. foodstuffs or drinking water). We offer corrosion resistance coating service for steel pipe elbow, our coating service includes light oiling, black painting, FBE coating, 2 layers or 3 layers PE coating, hot-dip galvanizing.

ASME B16.9 Standard covers overall dimensions, tolerances,ratings, testing, and markings for factory-made wrought buttwelding fittings in sizes NPS 1⁄2 through NPS 48 (DN 15 through DN 1200).

Download PDF| Nominal | Outside Diameter | 90° Elbows | 45° Elbows | 180° Returns | ||||

|---|---|---|---|---|---|---|---|---|

| Pipe Size |

Long Radius | Short Radius | Long Radius | Long Radius | ||||

| (inches) | (mm) | (inches) | Center to Face | Center to Face | Center to Face | Radius | Center to Center | Back to face |

| (inches) | (inches) | (inches) | (inches) | (inches) | (inches) | |||

| 1/2 | 21.3 | 0.84 | 1.5 | – | 5/8 | 2 | 1.875 | |

| 3/4 | 26.7 | 1.05 | 1.125 | – | 7/16 | 2.25 | 1.6875 | |

| 1 | 33.4 | 1.315 | 1.5 | 1 | 7/8 | 3 | 2.1875 | |

| 1.25 | 42.2 | 1.66 | 1.875 | 1.25 | 1 | 3.75 | 2.75 | |

| 1.5 | 48.3 | 1.9 | 2.25 | 1.5 | 1.125 | 3 | 4.5 | 3.25 |

| 2 | 60.3 | 2.375 | 3 | 2 | 1.375 | 4 | 6 | 4.1875 |

| 2.5 | 73 | 2.875 | 3.75 | 2.5 | 1.75 | 5 | 7.5 | 5.1875 |

| 3 | 88.9 | 3.5 | 4.5 | 3 | 2 | 6 | 9 | 6.25 |

| 3.5 | 101.6 | 4 | 5.25 | 3.5 | 2.25 | 7 | 10.5 | 7.25 |

| 4 | 114.3 | 4.5 | 6 | 4 | 2.5 | 8 | 12 | 8.25 |

| 5 | 141.3 | 5.563 | 7.5 | 5 | 3.125 | 10 | 15 | 10.3125 |

| 6 | 168.3 | 6.625 | 9 | 6 | 3.75 | 12 | 18 | 12.3125 |

| 8 | 219.1 | 8.625 | 12 | 8 | 5 | 12 | 24 | 16.3125 |

| 10 | 273.1 | 10.75 | 15 | 10 | 6.25 | 15 | 30 | 20.375 |

| 12 | 323.9 | 12.75 | 18 | 12 | 7.5 | 18 | 36 | 24.375 |

| NOMINAL PIPE SIZE NPS | ANGULARITY TOLERANCES | ANGULARITY TOLERANCES |

|---|---|---|

| Size | Off Angle Q | Off Plane P |

| ½ to 4 | 0.03 | 0.06 |

| 5 to 8 | 0.06 | 0.12 |

| 10 to 12 | 0.09 | 0.19 |

| 14 to 16 | 0.09 | 0.25 |

| 18 to 24 | 0.12 | 0.38 |

| 26 to 30 | 0.19 | 0.38 |

| 32 to 42 | 0.19 | 0.5 |

| 44 to 48 | 0.18 | 0.75 |

All dimensions are given in inches. Tolerances are equal plus and minus except as noted.

The ASME B16.9 pipe fittings can be used under the jurisdiction of the ASME Boiler & Pressure Vessel Code (BPVC) as well as the ASME Code for pressure piping. Referencing pressure ratings of flanges per ASME B16.5, they can be designated as Classes 150, 300, 600, 900, 1500 and 2500. The allowable pressure ratings for ASME B16.9 pipe fittings may be calculated as for straight seamless pipe of equivalent material in accordance with the rules established in the applicable sections of ASME B31 Code for pressure piping.

The design of butt welding pipe fittings made to ASME B16.9 shall be established by one of the following methods: (a) mathematical analyses contained in pressure vessel or piping codes; (b) proof testing; (c) experimental stress analysis with hydrostatic testing to validate experimental results; (d) detailed stress analysis with results evaluation.

Generally, ASME B16.9 pipe fittings shall be marked to show the following details: “trademark + material grade + wall thickness + size + heat number”. For example, “M ASTM A234 WP5 SCH80 6″ 385“. When steel stamps are used, care shall be taken so that

the marking is not deep enough or sharp enough to cause cracks or to reduce the wall thickness of the fitting below the minimum allowed.

The ASME B16.9 fittings may be made from an extensive range of mateirals covering (1) carbon and low-alloy steels in accordance with ASTM A234 and ASTM A420; (2) austenitic and duplex stainless steels in accordance with ASTM A403 and ASTM A815; (3) nickel alloys in accordance with ASTM B366; (4) aluminum alloys in accordance with ASTM B361; and (5) titanium alloys in accordance with ASTM B363.

Sizes 1/2″ – 48″

Pipe fitting dimensions are in either metric or Standard English.

Because pipe fitting covers Pipe Fitting Dimensions several aspects, only the most common pipe fitting sizes can be given here. The most applied version is the 90° long radius and the 45° elbow, while the 90° short radius elbow is applied if there is too little space. The function of a 180° elbow is to change direction of flow through 180°. Both, the LR and the SR types have a center to center dimension double the matching 90° elbows. These fittings will generally be used in furnesses or other heating or cooling units.

Some of the standards that apply to buttwelded fittings are listed below. Many organizations such as ASME, ASTM, ISO, MSS, etc. have very well developed standards and specifications for buttwelded fittings. It is always up to the designer to ensure that they are following the applicable standard and company specification, if available, during the design process.

Some widely used pipe fitting standards are as follows:

This is one of the reputed organizations in the world developing codes and standards.

The schedule number for pipe fitting starts from ASME/ANSI B16. The various classifications of ASME/ANSI B16 standards for different pipe fittings are as follows:

This is one of the largest voluntary standards development organizations in the world. It was originally known as the American Society for Testing and Materials (ASTM).

AWWA About – Established in 1881, the American Water Works Association is the largest nonprofit, scientific and educational association dedicated to managing and treating water, the world’s most important resource.

ANSI is a private, non-profit organization. Its main function is to administer and coordinate the U.S. voluntary standardization and conformity assessment system. It provides a forum for development of American national standards. ANSI assigns “schedule numbers”. These numbers classify wall thicknesses for different pressure uses.

The Manufacturers Standardization Society (MSS) of the Valve and Fittings Industry is a non-profit technical association organized for development and improvement of industry, national and international codes and standards for: Valves, Valve Actuators, Valve Modification, Pipe Fittings, Pipe Hangers, Pipe Supports, Flanges and Associated Seals

Piping codes imply the requirements of design, fabrication, use of materials, tests and inspection of various pipe and piping system. It has a limited jurisdiction defined by the code. On the other hand, piping standards imply application design and construction rules and requirements for pipe fittings like adapters, flanges, sleeves, elbows, union, tees, valves etc. Like a code, it also has a limited scope defined by the standard.

“Standards” on pipe fittings are based on certain factors like as follows:

BSP is the U.K. standard for pipe fittings. This refers to a family of standard screw thread types for interconnecting and sealing pipe ends by mating an external (male) with an internal (female) thread. This has been adopted internationally. It is also known as British Standard Pipe Taper threads (BSPT )or British Standard Pipe Parallel (Straight) threads (BSPP ). While the BSPT achieves pressure tight joints by the threads alone, the BSPP requires a sealing ring.

This is the Japanese industrial standards or the standards used for industrial activities in Japan for pipe, tube and fittings and published through Japanese Standards Associations.

National Pipe Thread is a U.S. standard straight (NPS) threads or for tapered (NPT) threads. This is the most popular US standard for pipe fittings. NPT fittings are based on the internal diameter (ID) of the pipe fitting.

We are manufacturer of Flange bolts & Nuts and supply high quality

The AN standard was originally designed for the U.S. Military. Whenever, a pipe fitting is AN fittings, it means that the fittings are measured on the outside diameter of the fittings, that is, in 1/16 inch increments.

For example, an AN 4 fitting means a fitting with an external diameter of approximately 4/16″ or ¼”. It is to be noted that approximation is important because AN external diameter is not a direct fit with an equivalent NPT thread.

Dash size is the standard used to refer to the inside diameter of a hose. This indicates the size by a two digit number which represents the relative ID in sixteenths of an inch. This is also used interchangeably with AN fittings. For example, a Dash “8” fitting means an AN 8 fitting.

ISO is the industrial pipe, tube and fittings standards and specifications from the International Organization for Standardization. ISO standards are numbered. They have format as follows:

“ISO[/IEC] [IS] nnnnn[:yyyy] Title” where

| Standard | Specification |

|---|---|

| ASTM A234 | Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service |

| ASTM A420 | Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Low-Temperature Service |

| ASTM A234 WPB | ASTM A234 WPB refers to a specific grade of carbon steel pipe fittings, which are widely used in pressure piping and pressure vessel fabrication for service at moderate and elevated temperatures. |

| ASME B16.9 | ASME B16.9 Standard covers overall dimensions, tolerances,ratings, testing, and markings for factory-made wrought buttwelding fittings in sizes NPS 1⁄2 through NPS 48 (DN 15 through DN 1200). |

| ASME B16.28 | ASME B16.28 Standard covers ratings, overall dimensions, testing, tolerances, and markings for wrought carbon and alloy steel buttwelding short radius elbows and returns. |

| MSS SP-97 | MSS SP-97 Standard Practice covers essential dimensions, finish, tolerances, testing, marking, material, and minimum strength requirements for 90 degree integrally reinforced forged branch outlet fittings of buttwelding, socket welding, and threaded types. |

| ASTM A403 | Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings. |

| DIN | EN | ASME |

|---|---|---|

| St 35.8 I St 35.8 III 15 Mo 3 13 CrMo 4 4 10 CrMo 9 10 St 35 N St 52.0 St 52.4 |

P235GH-TC1 P235GH-TC2 16Mo3 13CrMo4-5 10CrMo9-10 X10CrMoVNb9-1 P215NL P265NL L360NB L360NE P355N P355NL1 P355NH |

WPB WPL6 WPL3 WPHY 52 WP11 WP22 WP5 WP9 WP91 WP92 |

Visual Inspection is conducted on fittings to check any surface imperfections. Both fittings body and weld are checked for any visible surface imperfections such as dents, die marks, porosity, undercuts, etc. Acceptance as per applicable standard.

For packing of carbon steel flanges with painting,we would use the bubble wrap to protect the painting.For flanges without painting or oiled with long-term shipment,we would suggest client to use the anti-tarnish paper and plastic bag to prevent the rust.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.