Stainless Steel Pipe

Durable and corrosion-resistant stainless steel pipes for various applications.

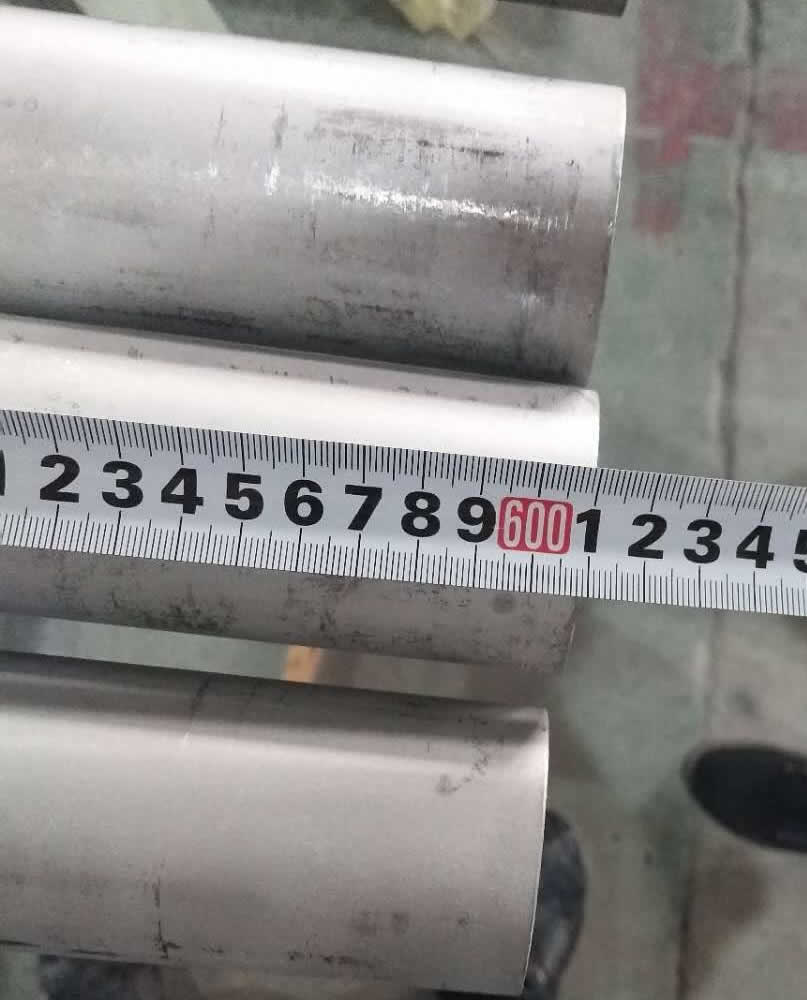

Stainless steel seamless pipe is a type of pipe made from stainless steel that does not have any welded joints or seams.

Seamless stainless steel pipe is used in applications where high temperature strength and superior corrosion resistance are critical.

Seamless pipes are thought to be able to withstand higher pressure, higher temperatures, higher mechanical stress and a corrosive atmosphere. It can be found in a wide range of applications such as in oil and gas, refinery, petrochemical, chemical, fertilizer, power, automotive, bearing, mechanical and structural.

Stainless steel is one of the most popular and versatile materials. Seamless stainless steel pipe is used in applications where high temperature strength and superior corrosion resistance are critical. Further, stainless steel is easy to clean and doesn’t tarnish.

Stainless steel is an iron alloy that contains a minimum of 10.5% chromium. Alloying elements such as nickel, molybdenum, titanium, carbon, nitrogen, and copper can boost the strength, formability, and other properties of stainless steel. Different alloys offer different levels of corrosion resistance.

Stainless steel alloys offer greater cryogenic toughness, a higher work hardening rate, increased strength and hardness, greater ductility, and a more attractive appearance compared to carbon steel.

It is the resistance of air, steam, water and other weak corrosive media and acid, alkali, salt and other chemical etching medium corrosion of steel pipes. Also known as acid - resistant stainless steel. It will be more and more engineering use and become increasingly popular, and prospects.

The production of our seamless steel pipes is tightly regulated and all of the pipes we stock have been fully tested to international standards to ensure we only supply the highest quality products.

Stainless steel pipe is resistant to rust and other corrosive attack. It is heat-resistant for high-performance and high-temperature use.

Seamless stainless steel pipe is a hollow steel bar, a large number of pipes used for conveying fluids, such as oil, gas, water, gas, steam,heat exchanger,mechinical machine.

| Product Name | Executive | Dimension | Steel Code / Steel Grade |

|---|---|---|---|

| Seamless Austenitic Stainless Steel Pipes | ASTM A312, A312M ASME SA312 / SA312M | OD: 1/4"-20" WT: SCH5S-SCH80S |

TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

| Seamless Austenitic Stainless Steel Tubing for General Service | ASTM A269 ASME SA269 | OD: 6.0-50.8mm WT: 0.8-10.0mm |

TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

| Seamless Austenitic Alloy-Steel Boiler, Super Heater and Heat-Exchanger Tubes | ASTM A213 / A213M ASME SA213 / SA213M | OD: 6.0-50.8mm WT: 0.8-10.0mm |

TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

| Seamless Duplex Stainless Steel Tubing for General Service | ASTM A789 / A789M | OD: 19.0-60.5mm WT: 1.2-5.0mm |

S31803, S32205, S32750 |

| Seamless Duplex Stainless Steel Pipes | ASTM A790 / A790M | OD: 3/4"-10" WT: SCH5S-SCH80S |

S31803, S32205, S32750 |

| Seamless Stainless Steel Mechanical Tubing | ASTM A511 | OD: 6.0-50.8mm WT: 0.8-10.0mm |

MT304, MT304L, MT304H, MT310, MT310S, MT316, MT316L, MT317, MT317L, MT321, MT321H, MT347 |

| Seamless Stainless Steel Tubes for Pressure Purposes | EN 10216 DIN 17456, 17458 | OD: 6.0-530.0mm WT: 0.8-34.0mm |

1.4301, 1.4307, 1.4541, 1.4401, 1.4404, 1.4571, 1.4878, 1.4432, 1.4462 |

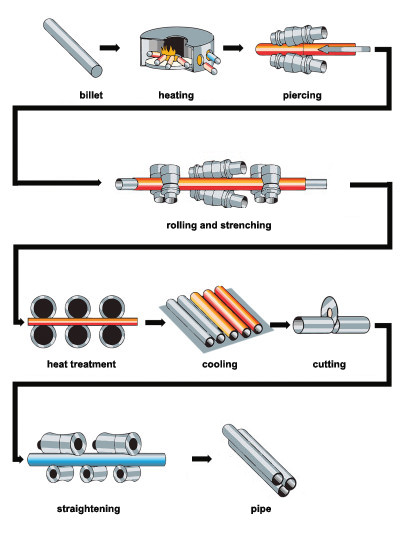

Seamless stainless steel pipe is made from solid stainless steel bar which is called billet. By using different processing techniques such as extruding, gun drilling or piercing, the steel bars are produced to be steel tubes.

A heat exchanger is a piece of equipment designed from one medium to another for efficient heat transfer. The application areas of the Stainless Steel Seamless pipes: Heat Exchanger Tube specifically cover the following: Apparatuses and heat exchangers for piping systems.

The areas of application in the fertiliser industry primarily include the following: Melamine plants high-pressure tubes and piping systems apparatus and heat exchangers of urea synthesis ethylene plants.

The fields of operation in the chemical and petrochemical industries primarily include the following: Melamine plants high-pressure tubes and piping systems apparatus and heat exchangers of urea synthesis ethylene plants.

Our tubes and pipes are used mainly for heat exchangers in power plants and the energy sector. Environmental systems and waste incineration plants also have the same field of application: reheater superheaters.

In the fields of discovery, manufacturing and processing, we develop tubes for shipbuilding. Stainless Steel 304 Pipes for use in ship construction.

SS Seamless steel pipes for oil casing and tubing for offshore and onshore Oil & Gas applications in the domains of Production, Exploration and Processing.

Our pipes are primarily used in mechanical and plant engineering and construction in the following areas: food manufacturing, automobile technology, measurement and control technology, pumps, hydraulic cylinders, etc. Stainless Steel Seamless pipes is known as a half-finished product for fittings and tubes and pipes of flange output as a half-finished product for radially machined parts.

In the automotive field, DMV products are used especially in the following areas: Other important areas of use are hydraulic braking systems.

The SS Seamless pipes are used in petroleum, Connecting water, gas and other common fluids. Seamless steel pipes are common and can be found in residential walls, labs, and commercial and industrial structures underground and inside them.

Stainless Steel Seamless pipes for high temperature and pressure service

For high temperature and pressure operation, we sell a comprehensive range of Seamless steel pipes. The SS Seamless pipes are also used in the applications like containers, heating pipelines, and high temperature reheaters.

| Grade | Description |

|---|---|

| TP304 | General-purpose stainless steel with good corrosion resistance for most applications. Used for: Bar rails, Boat railings, Canopy supports, Chemical processing equipment, Chemical tubing, Column covers, Duct works, Feed-water tubes, Food preparation equipment, Food processing equipment, Heat exchanger tubes, Hypodermic needles, Ladders, Mechanical & structural components, Pharmaceutical processing equipment, Piping systems, Railings (architectural), Traffic barriers, Water pipes. |

| TP304H | Higher carbon content than 304L, for increased strength, particularly at elevated temperatures. |

| TP304L | Chemical plant and food processing equipment, where freedom from sensitization is required in plate thicknesses TP316/316L |

| TP316/316L | Used where higher corrosion resistance is required. Boat railings, Canopy supports, Chemical tubing, Column covers, Duct works, Feed-water tubes, Food preparation equipment, Food processing equipment, Heat exchanger tubes, Hypodermic needles, Ladders, Mechanical & structural components, Pharmaceutical processing equipment, Piping systems, Railings, Street (urban) furniture, Textile tubing, Traffic barriers, Water pipes. |

| TP316H | Similar oxidation resistance to TP 316. Main areas of application: Heat exchangers, furnaces, chemical and petrochemical plant. |

| TP321 | Heat exchanger tubing, Chemical processing tubing, Pressure tank tubing. Suitable for heat resisting applications to 800°C. |

| TP321H | This is the high carbon version of TP 321 which ensures greater creep resistance. Behaves much the same as TP 321 in oxidation resistance. Main applications: Heat exchangers, furnaces, boilers in chemical and petrochemical plant |

| TP316Ti | A titanium stabilized version of 316 used where good resistance to intergranular corrosion and high temperature strength is required. |

| TP317 | Chemical processing tubing, Dyeing equipment, Ink manufacturing equipment, Pulp & paper manufacturing equipment |

| TP347HFG | Mainly used for boilers in the termal power plant, reheaters and superheaters |

| Grade | Description |

|---|---|

| TP904L | High resistance to general corrosion in e.g. sulphuric and acetic acids, crevice corrosion, stress corrosion cracking, pitting in chloride bearing solutions. |

| Grade | Description |

|---|---|

| TP405 | Used for applications where hardening upon cooling from high temperatures must be avoided. Has excellent long-time stability up to 1200°F. |

| TP410 | General purpose grade for use in mildly corrosive environments |

| TP430 | Mechanical & structural tubing, Architectural tubing, Heat exchanger tubing, Condensers, Re-heaters, Evaporators. |

| Grade | Description |

|---|---|

| S31803 |

Typically used in heat exchangers, gas scrubbers, fans, chemical tanks, flowlines, marine and refinery applications. |

| S32750 |

Used in oil & gas, chemical process, power industries. At that heat-exchangers are main application. |

| S31254 |

With high levels of chromium, molybdenum, and nitrogen is especially suited for high-chloride environments such as brackish water, seawater and other high-chloride process streams. |

When welding seamless stainless steel pipes, in order to reduce the tendency of hot cracking, the weld structure design generally contains a small amount of ferrite, and the control of the ferrite content is mainly realized by the alloy composition. Austenitic stainless steel welds contain more than 3% ferrite, which can effectively avoid solidification cracks, but too much ferrite will adversely affect performance.

The sensitization tendency of the weld metal is lower than that of the base metal. There is ferrite in the weld, its Cr content is higher than that of austenite, and the diffusion rate of Cr in ferrite is much faster than that of austenite. However, M23C6 carbides tend to precipitate at the pitted ferrite-austenite interface. Instead of precipitation at the relatively flat austenite-austenite interface, the rapid diffusion of chromium in ferrite can overcome the problem of chromium deficiency at grain boundaries. These factors greatly limit the sensitization of austenitic stainless steel welds containing ferrite to prevent intergranular corrosion of stainless steel water pipes.

Austenitic stainless steel weld metals containing a small amount of ferrite are corrosion resistant and contain no ferrite in most corrosive environments, corresponding to the parent metal. However, in organic acids, these media selectively attack ferrite. When the ferrite content in the weld metal is greater than 5FN, corrosion will proceed along the ferrite network, resulting in serious damage to the weld.

Ferrite is formed in the austenitic stainless steel weld metal as a secondary phase strengthening. Compared with the base metal and heat-affected zone, the yield strength is significantly improved, while the ductility is comparable. Increasing the ferrite content in the weld metal can significantly increase the strength at room temperature, but the strength at high temperature is slightly improved. Ferrite is a harmful phase of stainless steel water pipes in high temperature environment.

(1) Creep damage of ferrite

The continuous ferrite network in the weld metal promotes rapid creep damage due to earlier crack initiation than the ferrite-austenite interface. At this point the ferrite content should be below 5FN to prevent the formation of a continuous ferrite network

(2) Ferrite embrittlement at 475°C

Fe-Cr alloys with a Cr content of 15% to 70% will produce severely brittle Cr-rich ferrite and iron-rich ferrite when heated to 425°C to 550°C. The ferrite phase of the austenitic stainless steel weld metal is essentially ferrite embedded in the austenite matrix (Cr20-30%, Ni4%-5%). Therefore, if it stays in the temperature range of 425 ℃ ~ 550 ℃ for a long time (about 5000h), the ferrite phase will become brittle, the hardness will increase, and the plasticity and toughness will be damaged. Short-term heating above 550 °C can eliminate this embrittlement phenomenon, but long-term heating will cause σ-phase embrittlement.

At low temperatures, austenitic stainless steels exhibit good strength, ductility, and toughness; whereas ferritic undergoes a brittle transformation. Therefore, the use of stainless steel water pipes at low temperatures requires a low ferrite content in the weld.

Small amounts of ferrite in austenitic stainless steel welds can reduce low temperature toughness. When the ferrite content in the weld reaches FN=10, the low temperature toughness will decrease by 50%.

The low temperature toughness of stainless steel pipe is not only related to the ferrite content, but also related to the cleanliness of the weld. Tests have shown that the oxygen content of the deposited metal of the basic low-hydrogen electrode is lower than that of the titanium-calcium electrode, and the weld toughness is also better. The oxygen content of the deposited metal in inert gas shielded welding is lower than that of slag shielded welding, and the weld toughness is also better. Ultra-low carbon welding materials have less intergranular precipitation of deposited metal and good welding toughness.

When heat treatment is required after welding or high-temperature service, the ferrite number of weld metal measured before post-weld heat treatment shall not exceed 10FN. When the stainless steel pipe is used in a low temperature environment below -100°C, the low temperature impact test of the weld is carried out in accordance with relevant regulations; when it is used in a low temperature environment below -196°C, the ferrite content of the weld is less than 5FN. When stainless steel pipes are used in non-magnetic or special corrosive environments, they need to be controlled according to design requirements.

In order to solve the cumbersome and difficult to remember stainless steel grades, improve the practicability of the brand representation, and the contrast with the international standard grades, China has formulated the "Universal Code System for Steel and Alloy Grades", such as 06Cr19Ni10, corresponding to 304. Different grades of stainless steel have different ingredients, but they all have a national standard. The standards of each country are also different.

| No | China,GB | Japan | American | Korea | EUR | Indai | Australia | Tai Wan | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Old | New(07.10) | JIS | ASTM | UNS | KS | BS EN | IS | IS | CNS | |

| Austenitic stainless steel | ||||||||||

| 1 | 1Cr17Mn6Ni5N | 12Cr17Mn6Ni5N | SUS201 | 201 | S20100 | STS201 | 1.4372 | 10Cr17Mn6Ni4N20 | 201-2 | 201 |

| 2 | 1Cr18Mn8Ni5N | 12Cr18Mn9Ni5N | SUS202 | 202 | S20200 | STS202 | 1.4373 | - | 202 | |

| 3 | 1Cr17Ni7 | 12Cr17Ni7 | SUS301 | 301 | S30100 | STS301 | 1.4319 | 10Cr17Ni7 | 301 | 301 |

| 4 | 0Cr18Ni9 | 06Cr19Ni10 | SUS304 | 304 | S30400 | STS304 | 1.4301 | 07Cr18Ni9 | 304 | 304 |

| 5 | 00Cr19Ni10 | 022Cr19Ni10 | SUS304L | 304L | S30403 | STS304L | 1.4306 | 02Cr18Ni11 | 304L | 304L |

| 6 | 0Cr19Ni9N | 06Cr19Ni10N | SUS304N1 | 304N | S30451 | STS304N1 | 1.4315 | - | 304N1 | 304N1 |

| 7 | 0Cr19Ni10NbN | 06Cr19Ni9NbN | SUS304N2 | XM21 | S30452 | STS304N2 | - | - | 304N2 | 304N2 |

| 8 | 00Cr18Ni10N | 022Cr19Ni10N | SUS304LN | 304LN | S30453 | STS304LN | - | - | 304LN | 304LN |

| 9 | 1Cr18Ni12 | 10Cr18Ni12 | SUS305 | 305 | S30500 | STS305 | 1.4303 | - | 305 | 305 |

| 10 | 0Cr23Ni13 | 06Cr23Ni13 | SUS309S | 309S | S30908 | STS309S | 1.4833 | - | 309S | 309S |

| 11 | 0Cr25Ni20 | 06Cr25Ni20 | SUS310S | 310S | S31008 | STS310S | 1.4845 | - | 310S | 310S |

| 12 | 0Cr17Ni12Mo2 | 06Cr17Ni12Mo2 | SUS316 | 316 | S31600 | STS316 | 1.4401 | 04Cr17Ni12Mo2 | 316 | 316 |

| 13 | 0Cr18Ni12Mo3Ti | 06Cr17Ni12Mo2Ti | SUS316Ti | 316Ti | S31635 | - | 1.4571 | 04Cr17Ni12MoTi20 | 316Ti | 316Ti |

| 14 | 00Cr17Ni14Mo2 | 022Cr17Ni12Mo2 | SUS316L | 316L | S31603 | STS316L | 1.4404 | -02Cr17Ni12Mo2 | 316L | 316L |

| 15 | 0Cr17Ni12Mo2N | 06Cr17Ni12Mo2N | SUS316N | 316N | S31651 | STS316N | - | - | 316N | 316N |

| 16 | 00Cr17Ni13Mo2N | 022Cr17Ni13Mo2N | SUS316LN | 316LN | S31653 | STS316LN | 1.4429 | - | 316LN | 316LN |

| 17 | 0Cr18Ni12Mo2Cu2 | 06Cr18Ni12Mo2Cu2 | SUS316J1 | - | - | STS316J1 | - | - | 316J1 | 316J1 |

| 18 | 00Cr18Ni14Mo2Cu2 | 022Cr18Ni14Mo2Cu2 | SUS316J1L | - | - | STS316J1L | - | - | - | 316J1L |

| 19 | 0Cr19Ni13Mo3 | 06Cr19Ni13Mo3 | SUS317 | 317 | S31700 | STS317 | - | - | 317 | 317 |

| 20 | 00Cr19Ni13Mo3 | 022Cr19Ni13Mo3 | SUS317L | 317L | S31703 | STS317L | 1.4438 | - | 317L | 317L |

| 21 | 0Cr18Ni10Ti | 06Cr18Ni11Ti | SUS321 | 321 | S32100 | STS321 | 1.4541 | 04Cr18Ni10Ti20 | 321 | 321 |

| 22 | 0Cr18Ni11Nb | 06Cr18Ni11Nb | SUS347 | 347 | S34700 | STS347 | 1.455 | 04Cr18Ni10Nb40 | 347 | 347 |

| Austenitic ferritic stainless steel (duplex stainless steel) | ||||||||||

| 23 | 0Cr26Ni5Mo2 | - | SUS329J1 | 329 | S32900 | STS329J1 | 1.4477 | - | 329J1 | 329J1 |

| 24 | 00Cr18Ni5Mo3Si2 | 022Cr19Ni5Mo3Si2N | SUS329J3L | - | S31803 | STS329J3L | 1.4462 | - | 329J3L | 329J3L |

| 0Cr18Ni10Ti Iron type stainless steel | ||||||||||

| 25 | 0Crl3Al | 06Crl3Al | SUS405 | 405 | S40500 | STS405 | 1.4002 | 04Cr13 | 405 | 405 |

| 26 | - | 022Cr11Ti | SUH409 | 409 | S40900 | STS409 | 1.4512 | - | 409L | 409L |

| 27 | 00Cr12 | 022Cr12 | SUS410L | - | - | STS410L | - | - | 410L | 410L |

| 28 | 1Cr17 | 10Cr17 | SUS430 | 430 | S43000 | STS430 | 1.4016 | 05Cr17 | 430 | 430 |

| 29 | 1Cr17Mo | 10Cr17Mo | SUS434 | 434 | S43400 | STS434 | 1.4113 | - | 434 | 434 |

| 30 | - | 022Cr18NbTi | - | - | S43940 | - | 1.4509 | - | 439 | 439 |

| 31 | 00Cr18Mo2 | 019Cr19Mo2NbTi | SUS444 | 444 | S44400 | STS444 | 1.4521 | - | 444 | 444 |

| Martensitic stainless steel | ||||||||||

| 32 | 1Cr12 | 12Cr12 | SUS403 | 403 | S40300 | STS403 | - | - | 403 | 403 |

| 33 | 1Cr13 | 12Cr13 | SUS410 | 410 | S41000 | STS410 | 1.4006 | 12Cr13 | 410 | 410 |

| 34 | 2Cr13 | 20Cr13 | SUS420J1 | 420 | S42000 | STS420J1 | 1.4021 | 20Cr13 | 420 | 420J1 |

| 35 | 3Cr13 | 30Cr13 | SUS420J2 | - | - | STS420J2 | 1.4028 | 30 Cr13 | 420J2 | 420J2 |

| 36 | 7Cr17 | 68Cr17 | SUS440A | 440A | S44002 | STS440A | - | - | 440A | 440A |

In the production process, because the actual size is difficult to meet the nominal pipe size requirement, that is, it is often larger or smaller than the nominal size, so the standard stipulates that there is a difference between the actual size and the nominal size of the stainless steel pipe.

A positive difference is called a positive deviation, and a negative difference is called a negative deviation.

Outside diameter (OD), wall thickness and length are three basic parameters in the process of manufacture and distribution for stainless steel tube & pipe, and these parameters have been standardized.

Outer diameter and wall thickness are particularly important, they are not only the basic support for meeting the design requirements of various types of applications such as strength, stiffness and fluid delivery, but also have a decisive influence on the subsequent processing, therefore, standards for stainless steel tube & pipe diameter and wall thickness of the manufacturing accuracy (tolerance) should been standardized.

A. Nominal Pipe size: It is the nominal size specified in standards such as ASME B36.10m and ASME B36.19m. It is the ideal size that users and manufacturers hope to obtain, and it is also the order size specified in the contract.

B. Actual Pipe size: It is the actual size obtained during the production process. This size is often larger or smaller than the nominal size. The phenomenon of being larger or smaller than the nominal size is called deviation.

European stainless steel tube & pipe standards specify 4 classes outer diameter and wall thickness in percentage or absolute value on the basis of nominal dimension.

Generally, larger diameter or heavy wall thickness stainless steel pipe use percentage, small diameter or thin wall thickness stainless steel tube use absolute value.

European stainless steel tube & pipe standards specify 4 classes outer diameter and wall thickness in percentage or absolute value on the basis of nominal dimension.

Generally, larger diameter or heavy wall thickness stainless steel pipe use percentage, small diameter or thin wall thickness stainless steel tube use absolute value.

| Standard | Manufacturing Process & Type | Outer Diameter Tolerance | Wall Thickness Tolerance | Others | |

|---|---|---|---|---|---|

| OD (Mm) | Class | ||||

| EN10216-5 | Hot Finished Seamless Tube | 219.1-610 | D1 | +22.5%T,-15%T | T/D≤0.05 |

| T1 | T/D≤0.09 | ||||

| T2 | T/D>0.09 | ||||

| 30-219.1 | D2 | T1 | |||

| T2 | |||||

| Cold Finished Seamless Tubes | ≤219.1 | D3 | T3 | ||

| D4 | T4 | Agreement | |||

| EN10297-2 | Hot Finished Seamless Tube | D1 | T1 | ||

| D2 | T2 | Agreement | |||

| Cold Finished Seamless Tubes | D3 | T3 | |||

| D4 | T4 | Agreement | |||

| EN10217-7 | Welded Tubes | >168.3 | D2 | T3 | |

| ≤168.3 | D3 | T3 | |||

| D4 | T3 | Agreement | |||

| EN10296-2 | Welded Tubes | >168.3 | D2 | T3 | |

| ≤168.3 | D3 | T3 | |||

| ≤114.3 | D4 | T3 | Agreement | ||

| EN10312 | Welded Tubes | Series 1 | D4 | T3 | T=0.6-2 Mm |

| Series 2 | D3 – D4 | T3 – T4 | T=1-3 Mm | ||

From D1 to D4 class for outer diameter, and T1 to T4 for wall thickness tolerance comply to DIN EN ISO 1127 standard, stainless steel tubes – Dimensions, tolerances and conventional masses per unit length.

| Outside Diameter | Wall Thickness | ||

|---|---|---|---|

| Class | Tolerance | Class | Tolerance |

| D1 | ±1.5%, Or ±0.75 Mm Min. | T1 | ±15%, Or ±0.6 Mm Min. |

| D2 | ±1.0%, Or ±0.5 Mm Min. | T2 | ±12.5%, Or ±0.4 Mm Min. |

| D3 | ±0.75%, Or. ±0.3 Mm Min. | T3 | ±10%, Or ±0.2 Mm Min. |

| D4 | ±0.50%, Or ±0.1 Mm Min. | T4 | ±7.5%, Or ±0.15 Mm Min. |

| T5 | +/- 5.0 %, Or +/- 0.10 Mm Min. | ||

The tolerances on outside diameter and thickness from above table, greater value shall be selected.

EN 10312 has specific values in table series 1 and series 2.

America standard has two standard rules to specify outside diameter and thickness, ASTM A999 / A999M and A1016 / A1016M.

| ASTM A999 | ASTM A1016 |

|

|

But A511 for seamless stainless steel mechanical tubing and A554 welded stainless steel mechanical tubing not conform to above standards, they have separate outside diameter and thickness tolerances.

| Standard | Manufacturing & delivery condition | Outside Diameter OD / mm |

OD tolerance mm | Thickness T / mm |

T tolerance mm | |

|---|---|---|---|---|---|---|

| Minimum | Average | |||||

| ASTM A1016 A1016M |

Hot drawn seamless tubes | <=100 | +0.4, -0.8 | <=2.4 | +0.4t, 0 | |

| 100 – 200 | +0.4, -1.2 | 2.4 – 3.8 | +0.35t, 0 | |||

| 200 – 225 | +0.4, -1.6 | 3.8 – 4.6 | +0.33t, 0 | |||

| >=4.6 | +0.28t, 0 | |||||

| Cold drawn seamless tubes | <25 | +0.1, -0.11 | +0.20t, 0 | +/-0.10t | ||

| 25 – 40 | ||||||

| 40 – 50 | +/-0.2 | +0.22t, 0 | +/-0.10t | |||

| 50 – 65 | +/-0.25 | |||||

| 65 – 75 | +/-0.3 | |||||

| 75 – 100 | +/-0.38 | |||||

| 100 – 200 | +/-0.38, -0.04 | |||||

| 200 – 250 | +/-0.38, -1.14 | |||||

| Welded tubes | 40 – 50 | +/-0.2 | +0.18t, 0 | +/-0.10t | ||

| 50 – 65 | +/-0.25 | |||||

| 65 – 75 | +/-0.3 | |||||

| 75 – 100 | +/-0.38 | |||||

| 100 – 200 | +/-0.38, -0.04 | |||||

| 200 – 250 | +/-0.38, -1.14 | |||||

| ASTM A999 / M | Seamless tubes and welded tubes | <48.3 | +0.4, -0.8 | -0.125t | ||

| ASTM A312 / M | Seamless tubes and welded tubes | 48.3-114.3 | +/-0.8 | OD=10.3-73 | +0.20 t, -125t | |

| 168.3-219.1 | +1.6, -0.8 | t/OD<=5% OD=88.9-457.2 | +0.225 t, -125t | |||

| 219.1-457.2 | +2.4, -0.8 | t/OD>5% OD=88.9-457.2 | +0.15 t, -125t | |||

| Welded tubes | 508-660 | +3.2, -0.8 | OD>=508 | +0.175 t,-0.125 t | ||

| 711-864 | +4.0, -0.8 | t/OD<=5%, OD>=508 | +0.225 t,-0.125 t | |||

| Seamless tubes | 914-1209 | +4.8, -0.8 | t/OD>5%, OD>=508 | +0.15 t, -125t | ||

| ASTM A409 / M | Welded tubes | +/-0.2% | T<4.8 | |||

| +/-0.4% | t>=4.8 | |||||

| ASTM A358 / M | Welded tubes | +/-0.50% | ||||

| ASTM A511 | Seamless tubing | <=12.7 | +/-0.1 | +/-0.15t | ||

| 12.7-38.1 | +/-0.2 | +/-0.10t | ||||

| 38.1-88.9 | +/-0.3 | |||||

| 88.9-139.7 | +/-0.4 | |||||

| 139.7-203.1 | +/-0.8 | |||||

| 203.1-220 | +/-1.1 | |||||

| 220-325 | +/-1.6 | |||||

American standard outside diameter tolerance mainly used to represent the absolute value, over and below tolerances are often asymmetric, SS tube and pipe in American standard average tolerance can reach even higher than D4 class in EN ISO 1127 standard.

Wall thickness tolerance should be +/-10%t or better, and average thickness tolerance should be ( +/-20 – 22%t, 0 ), pipeline pipe has a larger tolerance, hot finished seamless pipe largest.

China has more quantity standards compared to European standards, but less than american standards, SS tube and pipe standards are similar with EU standards in system, and absorb favorable experience in USA specifications.

| Specification | Manufacturing | O.D(Mm) | O.D Tolerance | W.T(Mm) | W.T Tolerance | |

|---|---|---|---|---|---|---|

| GB13296 | Cold Rolled Seamless Pipe | 6-30 | ±0.15/-0.2 | 1-3 | +20% | -0% |

| >30-50 | ±0.3 | >3 | +22% | -0% | ||

| >50 | ±0.75% | Also Average Wall | ||||

| GB/T14976 | Cold Rolled Seamless Tube | 6-10 | ±0.15 | 1-3 | +12.5% | -12.5% |

| 10-30 | ±0.2 | >3 | +12.5% | -10% | ||

| 30-50 | ±0.3 | Average Wall, +22% | ||||

| >50 | ±0.8% | |||||

Stainless steel tube & pipe wall thickness tolerance are the same as the general accuracy of American ASTM / ASME and EU standards, but slightly lower than the high requirements of the EU standards.

Stainless steel tube & pipe outer diameter tolerances are mostly lower than American standards, and approaching the EU standards. it is more reasonable that the American standard specify the OD tolerance is tight, compared to thickness tolerance.

China GB standards and EU standard have no weight tolerance specified, seamless tube & pipe in GB standard delivery goods as actual weight or theoretical weight, welded tube & pipe as theoretical weight or actual weight.

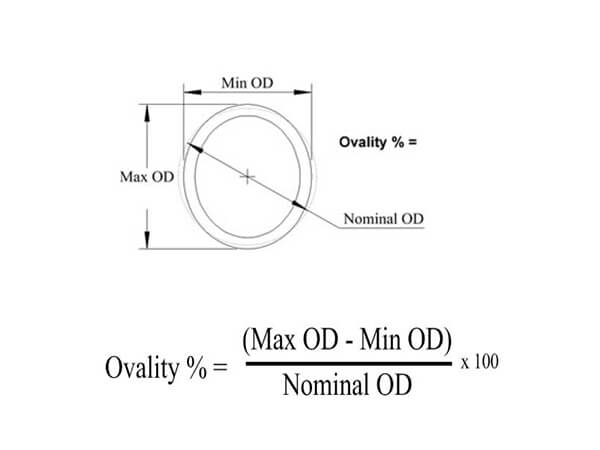

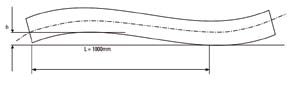

Out of roundness, sometimes referred to as ovality is tube or pipe on the same cross-section of the outer diameter, roundness or ovality is difference between the maximum and minimum dimensions of outside diameter, is carefully measured the high and low points at any one section of the tube or pipe.

Concentricity or eccentricity refers to tube & pipe wall thickness variations, if need a high precision in tube tolerance, or fit into other tube or parts, which need a good concentricity.

Concentricity be contained wall thickness tolerance specified in EU standard, and just specified in ASTM A1016/M OD≥50 mm and t≥5.6 mm thick wall stainless steel tube the same cross section thickness varieties.

For seamless tube,

WTmax – WTmin ≤ ±10% (WTmax + WTmin) / 2

For welded tube,

WTmax – WTmin ≤ 5% (WTmax + WTmin) / 2

Standard pipes and tubes are supplied straightened to the eye: for special applications the permissible deviation from the straight line may be agreed between purchaser and tube manufacturer; the maximum permissible deviation from the straight line related to the length of measurement L is to be indicated, e.g. 1mm/1000mm.

| OD Mm ≤ | OD Inches ≤ | Wall | Straightness Commercial | FT Achievable Mm |

|---|---|---|---|---|

| 15.9 | 0.625 | All Sizes | 1 In 600 | 1 In 2000 |

| 25.4 | 1.00 | 2% Of OD Or Heavier | 1 In 600 | 1 In 1500 |

| 25.4 | 1.00 | Less Than 2% Of OD | 1 In 400 | 1 In 1000 |

Delivery length is also called the length required by the user or the length of the order. The standard has the following regulations on delivery length:

A. Normal length / Random Length (also called non-fixed-length length): Any stainless steel tube whose length is within the length range specified by the standard and has no fixed length requirement is called normal length. For example, the structural stainless steel pipe standard stipulates: hot-rolled (extruded, expanded) steel pipe 3000mm - 12000mm; cold drawn (rolled) steel pipe 2000mm - 10500mm.

B. Fixed Length: The fixed-length should be within the usual length range, which is a certain fixed-length dimension required in the contract. However, it is impossible to cut out the absolute fixed-length length in actual operation, so the standard stipulates the allowable positive deviation value for the fixed-length length.

The yield rate of production of fixed-length pipes is much lower than that of normal-length pipes, and it is reasonable for manufacturers to request price increases. The rate of price increase varies from company to company. Generally, the price increase is about 10% on the basis of the base price.

C. Length of double ruler: The length of the double ruler should be within the usual length. The contract should indicate the length of the single ruler and the multiples of the total length (for example, 3000mm×3, which is 3 multiples of 3000mm, and the total length is 9000mm). In actual operation, the allowable positive deviation of 20mm should be added to the total length, plus a margin for the incision of each single ruler length. Take the structural pipe as an example, the allowance for cutting is stipulated: 5-10mm for outer diameter ≤159mm; 10-15mm for outer diameter >159mm.

If there is no double-length deviation and cutting allowance in the standard, it should be negotiated by the supplier and the buyer and indicated in the contract. The double-length scale is the same as the fixed-length length, which will bring about a substantial reduction in the yield rate of the manufacturer. Therefore, it is reasonable for the manufacturer to raise the price, and the price increase is basically the same as the fixed-length length.

D. Range length: The range length of the stainless steel pipe is within the usual length range. When the user requires a fixed range length, it must be indicated in the contract.

For example: Usually the length is 3000-12000mm, and the range cut-to-length length is 6000-8000mm or 8000-10000mm.

It can be seen that the range length is looser than the fixed-length and double-length length, but it is much stricter than the usual length, which will also reduce the yield of production enterprises. Therefore, it is reasonable for the manufacturer to raise the price, and the price increase is generally about 4% above the base price.

Stainless steel density refers to substance mass per unit volume, it is one of typical property of stainless steel, commonly, density of stainless steel range from 7600 kg/m3 to 8000 kg/m3.

Stainless steel is a wide used material, containing at least 10.5% of Chromium, and other elements added to form stainless steel structure, these elements have Carbon, Silicon, Manganese, Phosphorus, Sulfur, Nickel, Molybdenum, Titanium and Copper, it is noted as high strength and excellent corrosion resistance.

Densities change depending on these alloy elements changing, different alloy content have different density value, even it is the same grade, it is difficult to calculate accurate density values, theoretic density value is given below for reference.

The following is the comparison of several commonly used stainless steel density, data may not be completely accurate, only for reference.

| Grade | Density ( G / Cm3 ) | Density ( Kg / M3 ) |

|---|---|---|

| 201 202 301 302 303 304 304L 304LN 305 321 |

7.93 | 7930 |

| 309S 310S 316 316L 316Ti 316LN 317 317L 347 |

7.98 | 7980 |

| 904L | 7.98 | 7980 |

| 2205 S31803 |

7.80 | 7800 |

| S32750 | 7.85 | 7850 |

| 403 410 410S 416 431 |

7.75 | 7750 |

| 440A | 7.74 | 7740 |

| 440C | 7.62 | 7620 |

| 420 | 7.73 | 7730 |

| 439 430 430F |

7.70 | 7700 |

| 434 | 7.74 | 7740 |

| 444 | 7.75 | 7750 |

| 405 | 7.72 | 7720 |

*These densities given at standard conditions for temperature and pressure condition.

304 And 316 Stainless Steel Densities

304 and 316 are the most used stainless steel grades, their densities are not the same, this decide by chemical composition and content, stainless steel 304 density is 7930 kg / m3, 316 density is 7980 kg / m3, so when calculating stainless steel weight, it is different between 304 and 316 stainless steel.

Stainless Steel Density Conversion, Kg/M3, G/Cm3 And Lbs/In3

Density of stainless steel calculated by dividing the mass by the volume, usually measured in g/cm3, kg/m3, and lbs/in3, each unit can be converted to other units.

Density Relations With Temperature And Pressure

Densities of stainless steel vary by changing either the temperature or the pressure, in general, increasing the temperature decreases the density, increasing the pressure always increases the density.

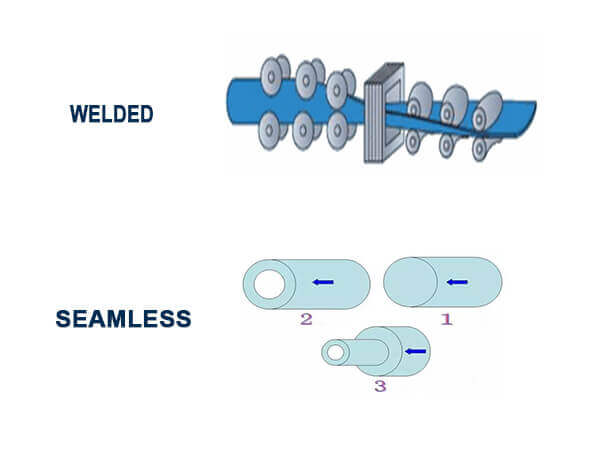

Seamless and welded are mainly two types stainless steel tube & stainless steel pipe, there is a debate whether seamless is better than welded for a long time.

Although with improved metallurgy and welding processes in welded tubes, the arguments typically focus on structural integrity and corrosion resistance in weld area.

Obviously, seamless and welded tubes & pipes difference is manufacturing process.

There are some cases where paying extra for a different, higher-performing alloy is necessary.

Depending on the outer dimension, wall thickness and final application, there are different ways of manufacturing welded tubes and pipes, and different manufacturing method.

Welded tube start from stainless steel strip and coil that is passed through grooved rollers till the shape is formed and the free edges are properly shaped for welding, cold forming is performed step by step from flat strip into a round profile, the edges are welded together as they approach the welding rolls.

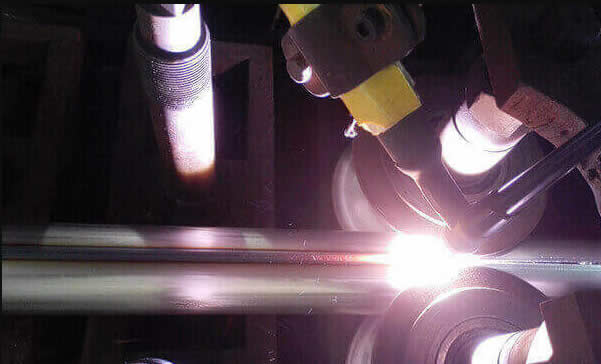

Typical welding method for strip welded tubes is traditionally autogenous tungsten inert gas (TIG), TIG welding method have some advantages that can effectively protect weld seam.

After welding outside and inside grinding of the weld seam, solution annealing or stress relieving may be necessary by application requirements.

Today, most of the modern welding lines are equipped with inline induction annealing, then straitening and calibration to control dimension of tube & pipe, cut to standard or special lengths, de-burred, NPD & DT testing and inspection should be carried out as standard or requirement.

When large outside diameter or heavy wall or both welded tubes & pipes required, there is a different welding method and process, for large diameter and heavy wall pipes, EFW, ERW and other welding methods can be used.

Starting from stainless steel plate or sheet, the forming is done in a roller bending machine or in a hydraulic press, then some steps are same with strip welded tubes.

For testing and inspection, large diameter sizes, radiography test (RT) and hydrostatic test (HT) are often required.

For large diameter welded pipes, double welding method can be accepted.

Chemical composition inspection, mechanical properties test(tensile strength,yield strength, elongation, flaring, flattening, bending, hardness, impact test), surface and dimension test,no-destructive test, hydrostatic test.

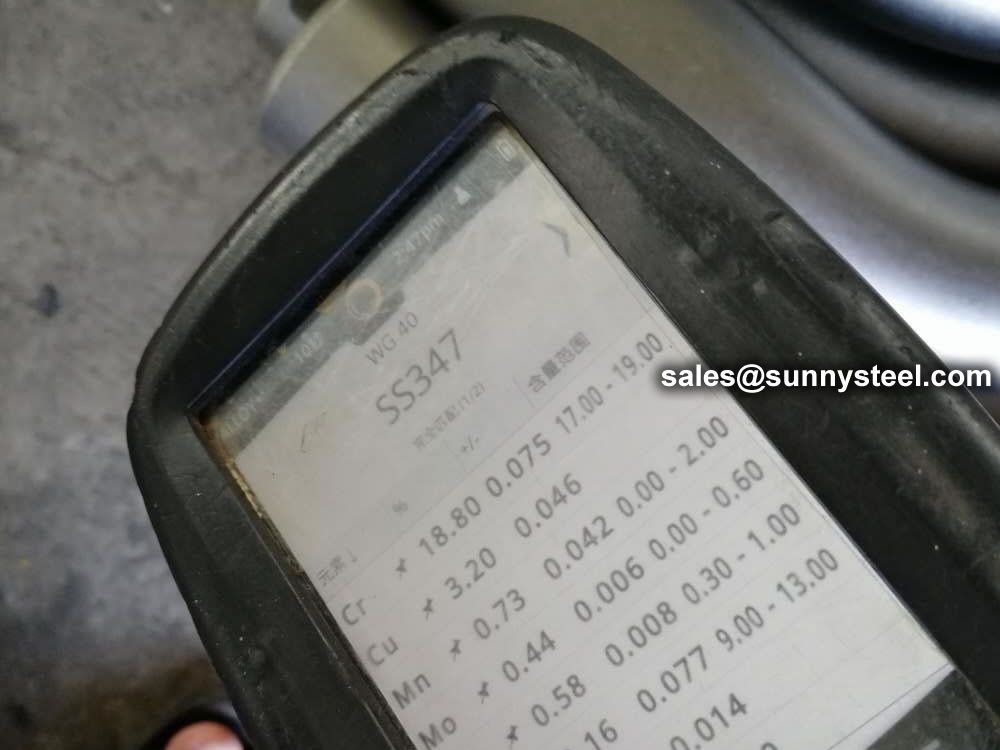

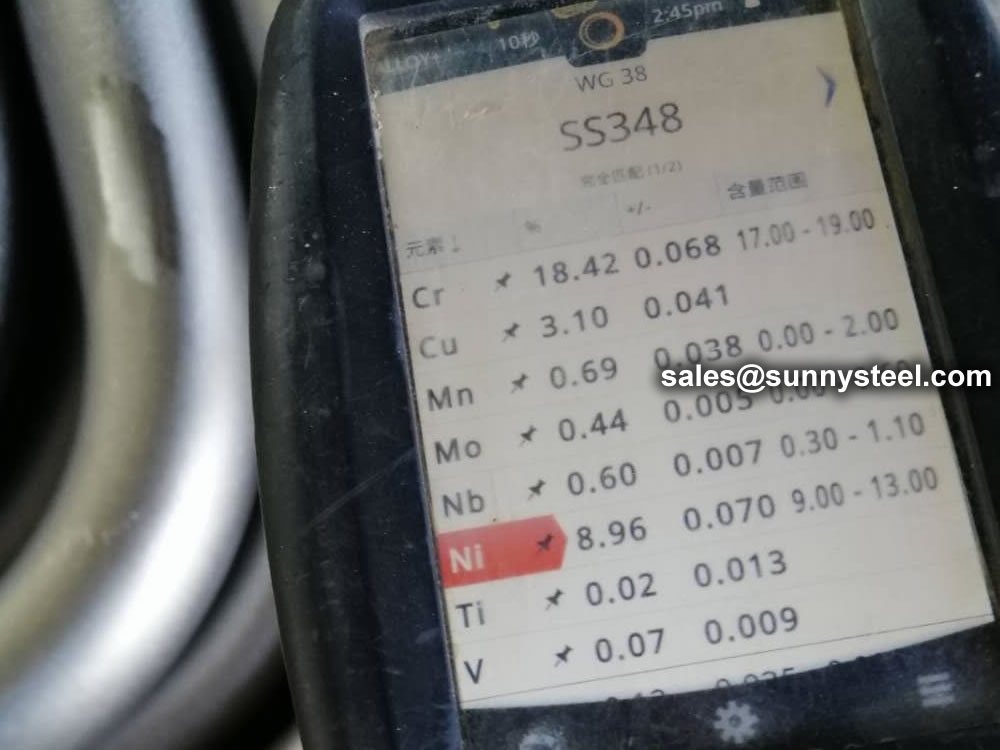

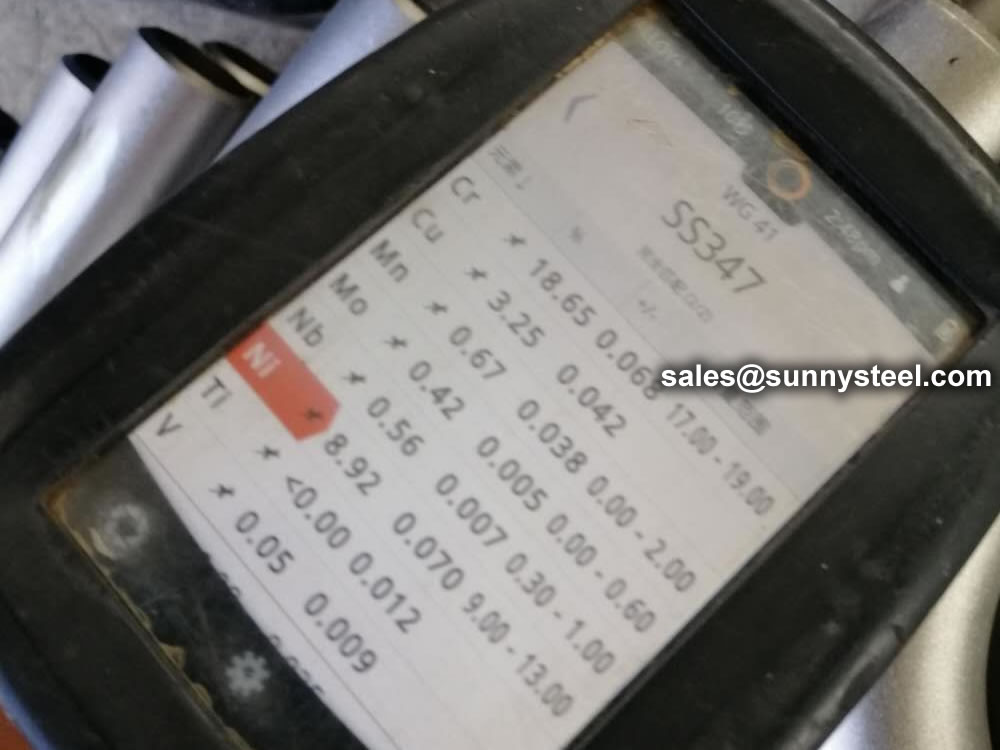

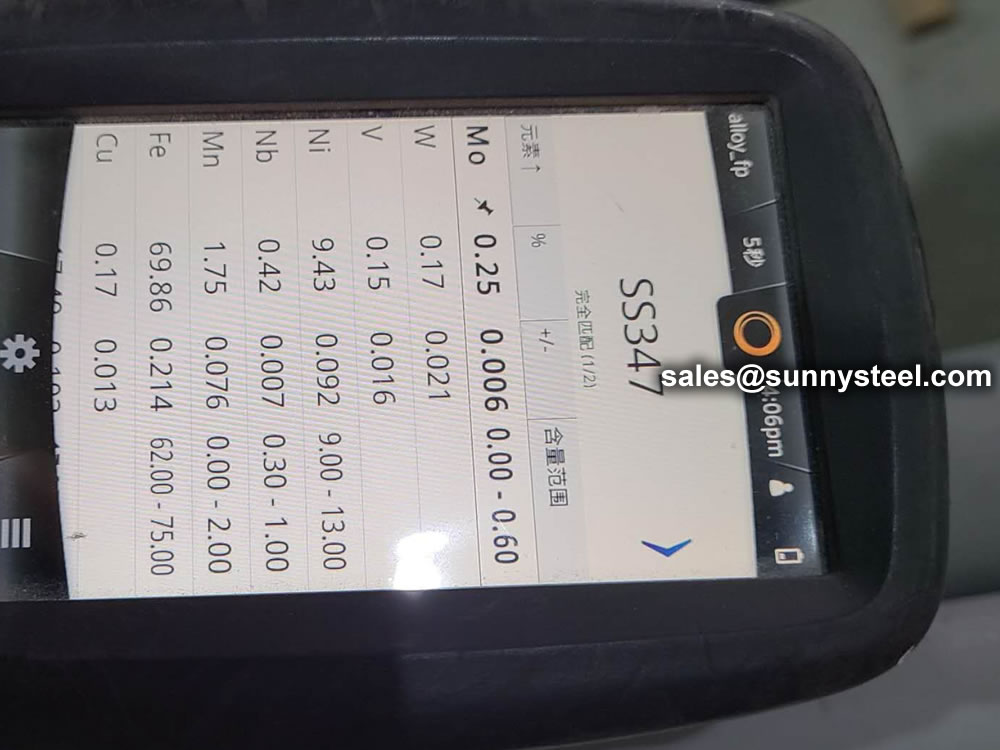

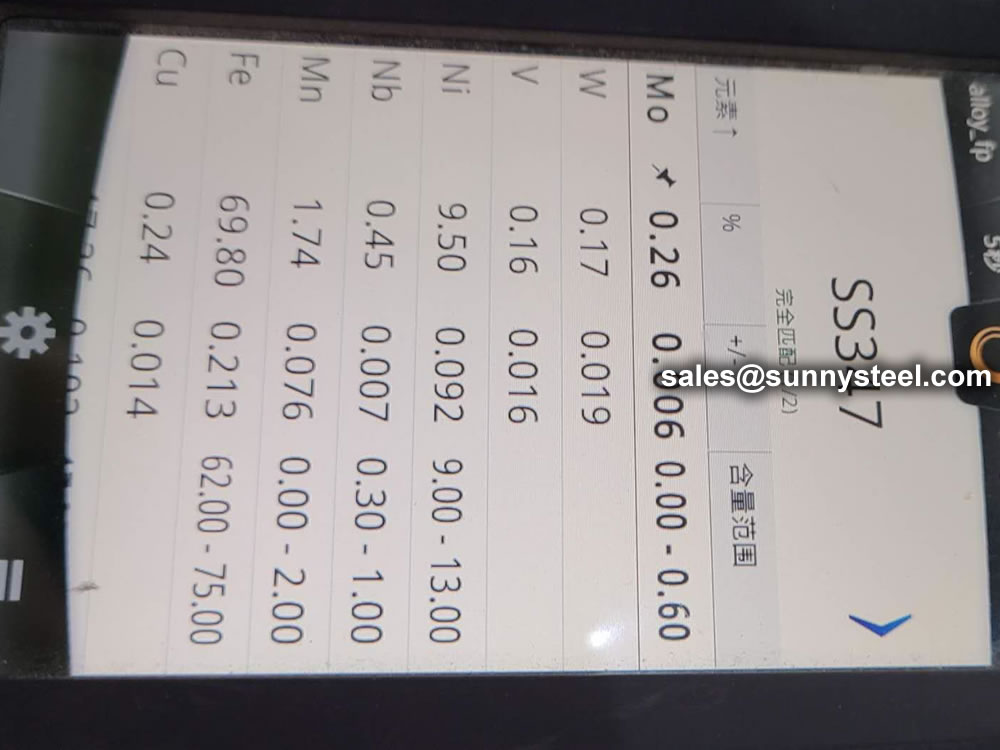

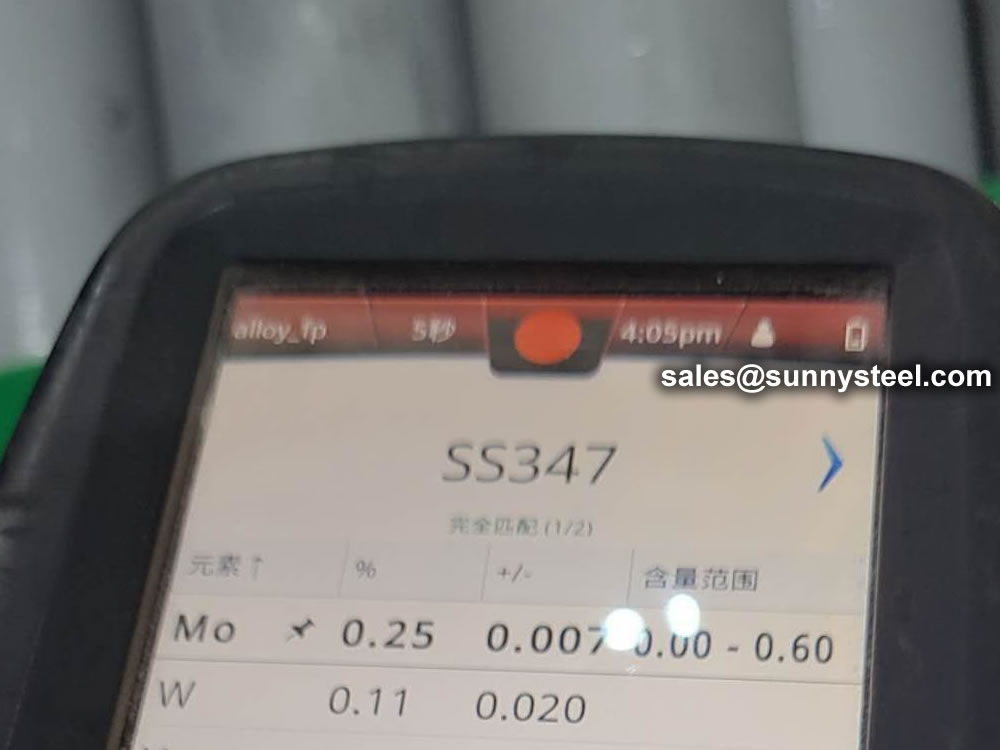

identification of the chemical composition of the metal used to manufacture the fitting. Uses PMI sensors, including X-ray fluorescence or optical emission spectrometry.

Steel pipe delivery status(condition): cold / hard (BK), cold / soft (BKW), after cold stress relief annealing (BKS), annealing (GBK), normalized (NBK).

| Term | Symbol | Explanation |

|---|---|---|

| Cold-finished/hard (cold-finished as-drawn) | BK | No heat treatment after the last cold-forming process. The tubes therefore have only low deformability. |

| Cold-finished/soft (lightly cold-worked) | BKW | After the last heat treatment there is a light finishing pass (cold drawing) With proper subsequent processing, the tube can be cold-formed (e.g. bent, expanded) within certain limits. |

| Annealed | GBK | After the final cold-forming process the tubes are annealed in a controlled atmosphere or under vacuum. |

| Normalized | NBK | The tubes are annealed above the upper transformation point in a controlled atmosphere or under vacuum. |

The general cold strip mills, volume should go through continuous annealing (CAPL unit) to eliminate cold hardening and rolling stress, or batch annealing reach the mechanical properties of the corresponding standard specifies. Cold rolled steel surface quality, appearance, dimensional accuracy better than hot-rolled plate, and right-rolled thin product thickness is about 0.18mm, so the majority of users favor.

Cold rolled steel coil substrate products deep processing of high value-added products. Such as electro-galvanized, hot dip galvanized, electro-galvanized fingerprint resistant, painted steel roll damping composite steel, PVC laminating steel plates, etc., so that the excellent quality of these products has a beautiful, high resistance to corrosion, has been widely used.

Cold rolled steel coil finishing after annealing, cut the head, tail, trimming, flattening, smooth, heavy volume, or longitudinal clipboard. Cold-rolled products are widely used in automobile manufacturing, household electrical appliances, instruments, switches, buildings, office furniture and other industries. Steel plate strapping package weight of 3 to 5 tons. Flat sub-volume typically 3 to 10 tons / volume. Coil diameter 6m.

Bare packing/bundle packing/crate packing/wooden protection at the both sides of tubes and suitably protected for sea-worthly delivery or as requested.

There are probably hundreds of different methods for packing a pipe, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.

Our packing can meet any needs of the customers.

Beveling Stainless Steel tubes contain one end angled, so that it mates with a complementary tube end. Tubes can be beveled for certain applications in order to make welding of stainless steel tubes easier, which saves weld prep time and money compared to hand cutting.

Eastern Steel can heat treat some 400 series stainless steel seamless tube. Heat treating realizes stress as a result of hardening, depending upon the chemistry of the metal being treated. Heat treating is also used for tempering, quenching, normalizing, and solution annealing.

During the honing/turning process, an abrasive rotating tool removes metal from the interior surface of a cylinder, pipe, or tube. The main purpose of honing is to finish the surface to a particular diameter and/or desired cylindrical geometric design. Honing is typically a secondary machining operation that completes a produce/part, relieves stress created during production, or corrects features of the finished product. A typical production cycle is to drill, ream, heat treat, then hone.

POSITIVE MATERIAL IDENTIFICATION (PMI)

In some cases, it may be necessary to complete additional positive material identification testing. Eastern Steel can complete this testing in house or we can work with an independent laboratory to complete the testing. Please contact us for specific requirements.

Ultrasonic Testing (UT) utilizes sound energy at high frequencies, in order to provide examinations and measurements of the stainless steel product. This aids in flaw detection/evaluation, dimensional measurements, etc.

Commonly used alloying elements and their effects are listed in the table given below.

| Alloying Elements | Effect on the Properties |

|---|---|

| Chromium | Increases Resistance to corrosion and oxidation. Increases hardenability and wear resistance. Increases high temperature strength. |

| Nickel | Increases hardenability. Improves toughness. Increases impact strength at low temperatures. |

| Molybdenum | Increases hardenability, high temperature hardness, and wear resistance. Enhances the effects of other alloying elements. Eliminate temper brittleness in steels. Increases high temperature strength. |

| Manganese | Increases hardenability. Combines with sulfur to reduce its adverse effects. |

| Vanadium | Increases hardenability, high temperature hardness, and wear resistance. Improves fatigue resistance. |

| Titanium | Strongest carbide former. Added to stainless steel to prevent precipitation of chromium carbide. |

| Silicon | Removes oxygen in steel making. Improves toughness. Increases hardness ability |

| Boron | Increases hardenability. Produces fine grain size. |

| Aluminum | Forms nitride in nitriding steels. Produces fine grain size in casting. Removes oxygen in steel melting. |

| Cobalt | Increases heat and wear resistance. |

| Tungsten | Increases hardness at elevated temperatures. Refines grain size. |

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.