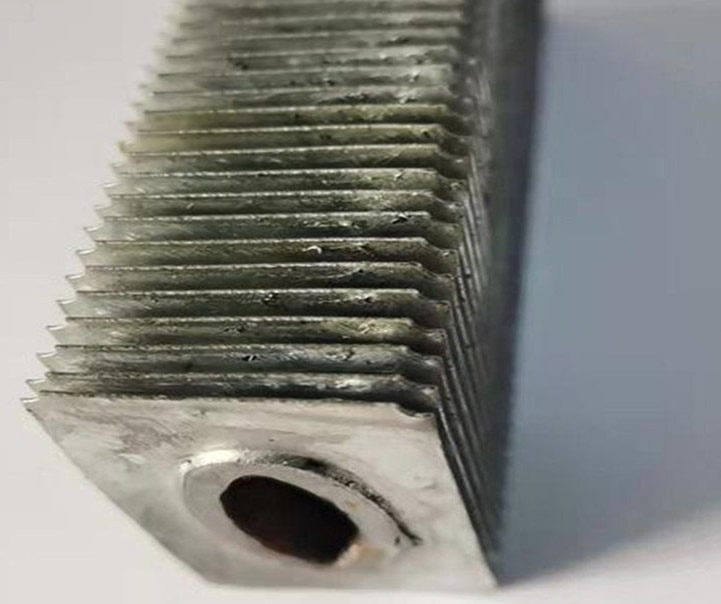

Elliptical finned tubes consist of a base tube that has an elliptical shape and is surrounded by fins.

Elliptical finned tube is a type of tube used in heat exchangers, in which external fins are elliptical in shape.

The fins are typically made of materials like aluminum or copper and are spirally or helically wrapped around the base tube. The elliptical shape of the tube and the arrangement of the fins help to enhance heat transfer efficiency.

Download PDFElliptical Finned Tube is an elliptical seamless tube as the base tube, which uses aluminum fin strips or copper fin strips to spirally and tightly wrap around the outer surface of the base tube under tension.

Elliptical Finned Tube is an elliptical seamless tube as the base tube, which uses aluminum fin strips or copper fin strips to spirally and tightly wrap around the outer surface of the base tube under tension. Elliptical Finned Tube is a heat exchange element consisting of a base tube elliptical tube and outer fins.

Because Elliptical Finned Tube has superior performance than round finned tube, Elliptical Finned Tube is receiving attention, and Elliptical Finned Tube has been widely used in ethylene, oil refining and other industrial fields. Elliptical Finned Tube is used in heat exchange equipment as a high-efficiency heat exchange element. The flow resistance outside the tube is small and the heat exchange efficiency is high, which makes the heat exchange equipment tend to be compact, lightweight, efficient and miniaturized. Although much research has been done on them, there is still a lot of research work to be done.

Elliptical finned tubes are commonly used in heat exchangers and boilers. They are suitable for applications where high heat transfer rates are required, such as in power plants, chemical processing plants, HVAC systems, and refrigeration systems. The elliptical shape and fin arrangement increase the surface area available for heat transfer, improving the overall efficiency of the heat exchanger.