Tubo preto DIN2458

DIN 2458 Tubes are carbon steel tubes with seams, which can be supplied black or galvanized, with smooth ends, beveled ends or with BSP or NPT threads.

Steel A179 boiler pipes, manufactured according to ASTM A179/A179M standards, are used primarily in heat exchangers and condensers due to their excellent heat transfer capabilities.

Download PDFThis article provides a detailed overview of A179 steel pipe and DIN 2458 standard, including their uses, technical specifications, and how to choose the appropriate standard.

A179 steel pipe is used for boilers and heat exchangers. It is known for its high tensile strength and resistance to high temperatures. The A179 specification covers requirements for seamless cold drawn carbon steel heat-exchanger and condenser tubes.

DIN 2458 is a German standard that specifies the dimensions and tolerances for seamless pipes used in various applications, including boilers and heat exchangers. It is often used to ensure that pipes meet precise measurements for performance and fit.

ASTM A179 is a standard specification for seamless cold-drawn low-carbon steel tubes used in tubular heat exchangers, condensers, and similar applications.

The ASTM A179 tubes are produced through a cold-drawing process, which helps to improve their dimensional accuracy and surface finish.

Steel A179 boiler pipe DIN 2458 are widely used in industries such as petroleum, chemical, medical, food, light industry, machinery, instrument, include industrial pipeline and mechanical structure parts, etc.

ASTM A179 covers minimum-wall thickness, seamless cold-drawn low-carbon steel tubes for tubular, heat exchanger, condensers, and other heat transfer services. seamless ASTM A 179 steel tube is supplied and produced by cold drawning method. Chemical composition contains carbon, manganese, phosphorus, and sulfur.

ASTMA179/ASME SA179 standard is applicable for steel pipes together with outside diameter of 1/8in-3in. (32 mm to 76.2 mm). Our rolling technology has reached the international advanced spot. JST is able to manufacture cold drawn seamless steel tubes with uniform wall depth. Their tolerance is relatively smaller standard your own.

When seamless carbon steel pipes are during the last cold drawing procedure, they will enter micro oxidization and non-oxidation heat treatment furnace for thermal treatment (Temperature is 1200℉ (650℃) if not more.). This makes the surface of cold drawn seamless steel tubes match the no oxide scale standards, and guarantees smooth surface and stable performance.

JST adopts professional hardness testing equipment to find out the hardness of seamless carbon steel pipes. The Rockwell hardness value not able to exceed 72 HRB.

Top rated program customers' requirements, we can analyze the cold drawn seamless steel tube advertise its chemical composition meet standards. We choose one from 250 pipes or select one in a furnace to investigate. If the product analysis fails, then choose another two seamless carbon steel pipes. All elements of two steel pipes tend to be in accordance with standards, and then these pipes can be delivered.

Note:

| OD(mm) | Wall Thickness Unit(mm) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 6.5 - 7 | 7.5 - 8 | 8.5 - 9 | 9.5 - 10 | 11 | 12 | |

| Φ25-Φ28 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ32 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ34-Φ36 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ38 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ40 | ● | ● | ● | ● | ● | |||||||||

| Φ42 | ● | ● | ● | ● | ● | |||||||||

| Φ45 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ48-Φ60 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ63.5 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ68-Φ73 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ76 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ80 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ83 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ89 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ95 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ102 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ108 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ114 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ121 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ127 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ133 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ140 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ146 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ152 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ159 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| Φ168 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| C | Si | Mn | P | S | Mo | Cr | V |

|---|---|---|---|---|---|---|---|

| 0.06-0.18 | / | 0.27-0.63 | ≤0.035 | ≤0.035 | / | / | / |

| Tensile Strength (Mpa) |

Yield Strength (Mpa) |

Elongation (%) |

Hardness (HRB) |

|---|---|---|---|

| ≥325 | ≥180 | ≥35 | ≤72 |

ASTM A450 covers carbon and low alloy steel tube. Steel samples shall be melt processed and shall either be ingot cast or strand cast. Heat and product analyses shall be performed on the steel materials. Steel specimens shall also undergo tensile tests and shall conform to required values of yield strength and elongation. Flattening test, reverse flattening test, flaring test, flange test, hardness test, hydrostatic test, air underwater pressure test, and nondestructive tests shall be performed on the steel materials.

| OD In (mm) | + | - | WT In(mm) | + | - |

|---|---|---|---|---|---|

| <1(25.4) | 0.10 | 0.10 | ≤1.1/2(38.1) | 20% | 0 |

| 11.1/2(25.438.1) | 0.15 | 0.15 | >1.1/2(38.1) | 22% | 0 |

| >1.1/2<2(38.150.8) | 0.20 | 0.20 | |||

| 2<2.1/2(50.863.5) | 0.25 | 0.25 | |||

| 2.1/2<3(63.576.2) | 0.30 | 0.30 | |||

| 34(76.2101.6) | 0.38 | 0.38 | |||

| >47.1/2(101.6190.5) | 0.38 | 0.64 | |||

| >7.1/29(190.5228.6) | 0.38 | 1.14 |

DIN 2458 Tubes are carbon steel tubes with seams, which can be supplied black or galvanized, with smooth ends, beveled ends or with BSP or NPT threads.

We are a DIN 2458 Pipes company specializing in steel pipes of various shapes and materials, which perfectly fit the demands of your work or construction project. We have a large stock ready for delivery and we serve the entire national market, with agility and competitive prices. Our company has been standing out in the market and we are a reference in quality service and honest prices. We always seek to provide our customers with the best in the world of steel. We work with the entire line of steel sheets, rolled, rectified and drawn steel bars to meet the most varied needs of our customers.

SunnySteel excellence in our products and services, we have a team of trained and highly qualified professionals, with great technical knowledge to provide full support to our customers, in addition to modern and high-tech equipment, which makes us the main DIN 2458 Pipes company, meeting the demands of the entire national market.

When you think about efficient DIN 2458 Pipes, don't hesitate, count on all our experience, much more than simply being the main DIN 2458 Pipes, our main objective is to promote safety and savings for our customers, meeting requests with maximum efficiency, we are proud of our work, we always prioritize seriousness and respect for customers, get in touch, we are at your disposal and it will be a great pleasure to serve you.

DIN 2458 Standard is applicable to the dimensions and conventional masses per unit length of welded steel pipes, in accordance with the technical conditions of delivery as stipulated in DIN 1628 Parts 1 to 4, DIN 17172 and DIN 17177. Furthermore, St37.2 welded pipe is also applicable to other technical conditions of delivery in which reference to DIN 2458 Standard is made.

It defines the sector, selected from DIN ISO 4200, within which welded steel pipes are standardised.Please note that it does not apply to precision steel tubes according to DIN 2393 and DIN 2394.

| Steel Grade | Material Number | Type of Deoxidation | C (max) | Si (max) | N | P (max) | S (max) | Addition of Nitrogen Fixing Elements |

|---|---|---|---|---|---|---|---|---|

| St 37.2 | 1.0037 | RR | 0.17 | -- | 0.009 | 0.050 | 0.050 | -- |

| Steel Grade | Material Number | Up to 16 (N/mm2 min) | 16 - 40 (N/mm2 min) | 40 - 65 (N/mm2 min) | Tensile (N/mm2) | Elongation after A5 (Longitudinal) (% min) | Elongation after A5 (Transverse) (% min) | Impact ISO V-notch test pieces at +20°C (Longitudinal) (/ min) | Impact ISO V-notch test pieces at +20°C (Transverse) (/ min) |

|---|---|---|---|---|---|---|---|---|---|

| St 37.2 | 1.0037 | 235 | 225 | 215 | 340 to 510 | 17 - 26 | --- | 27 | -- |

Get in touch with our professionals and request a quote for DIN 2458 Pipes.

Chemical composition inspection, mechanical properties test(tensile strength,yield strength, elongation, flaring, flattening, bending, hardness, impact test), surface and dimension test,no-destructive test, hydrostatic test.

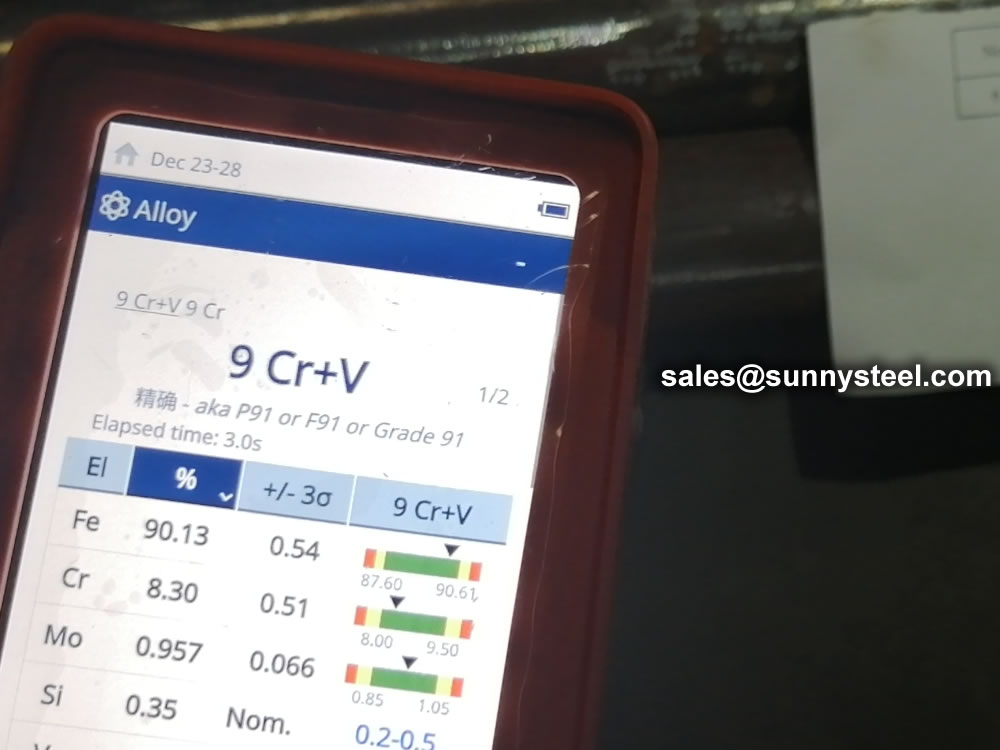

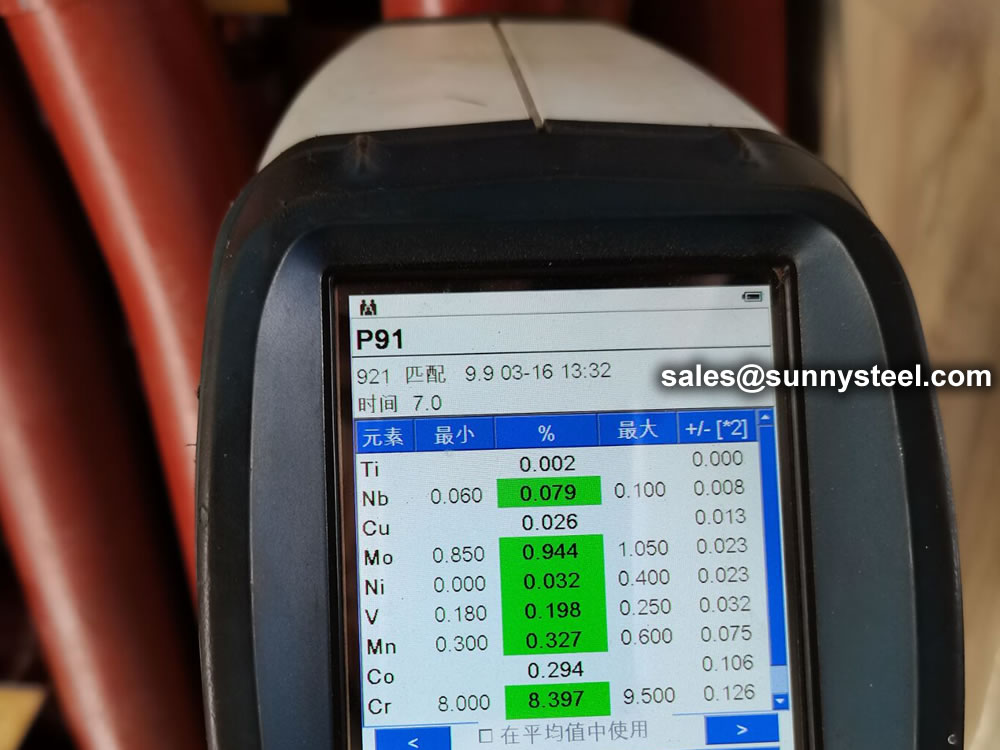

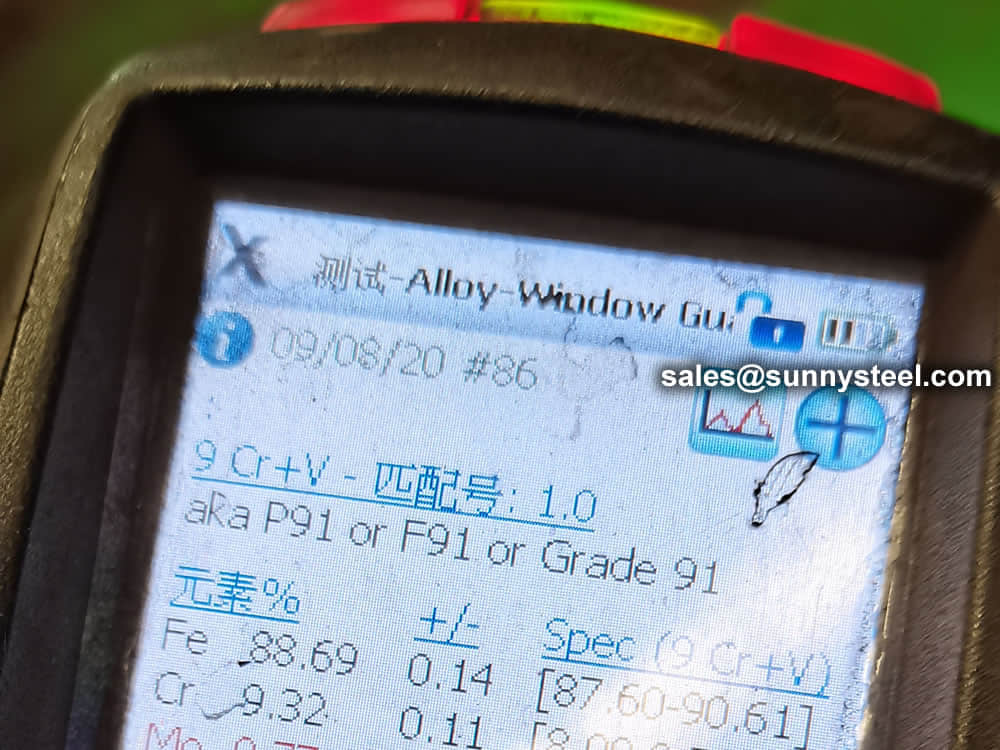

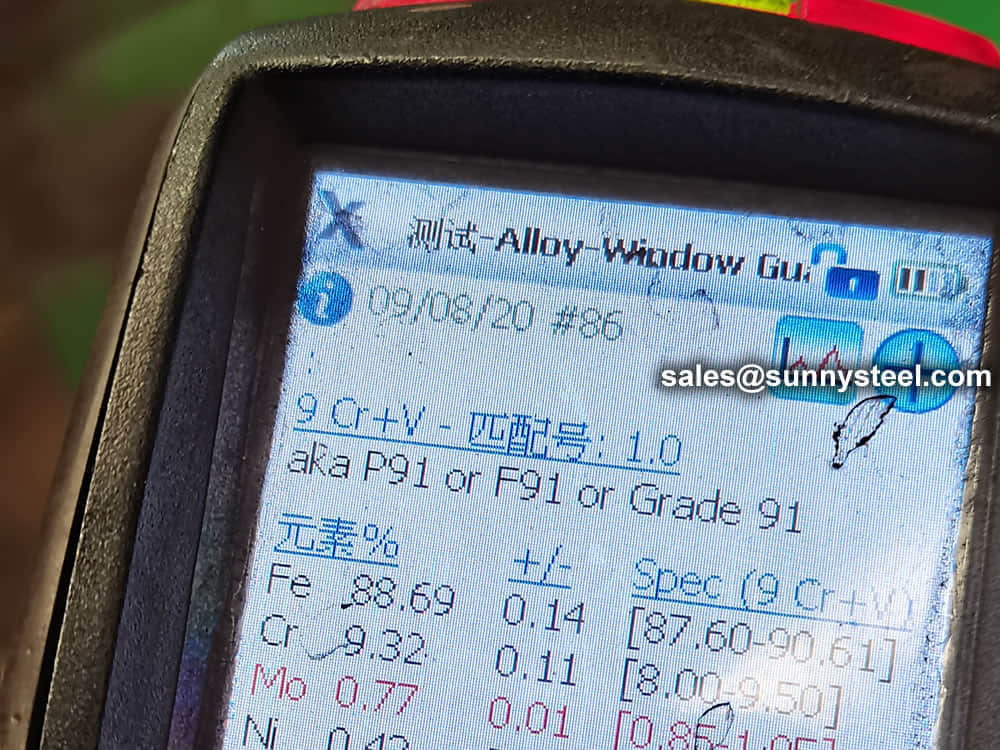

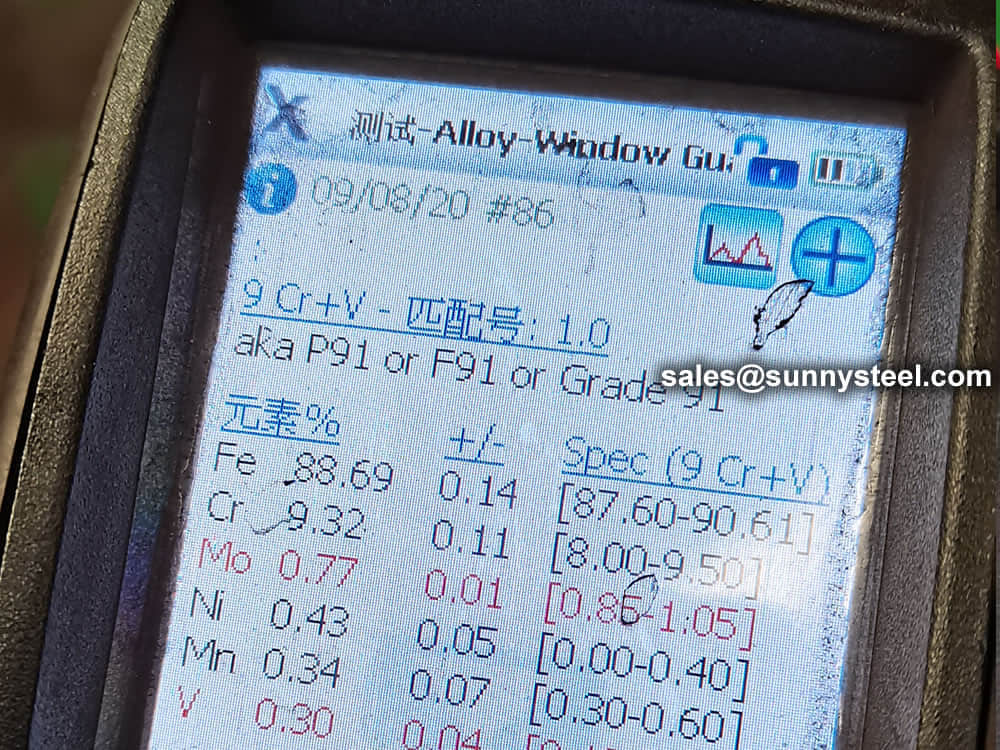

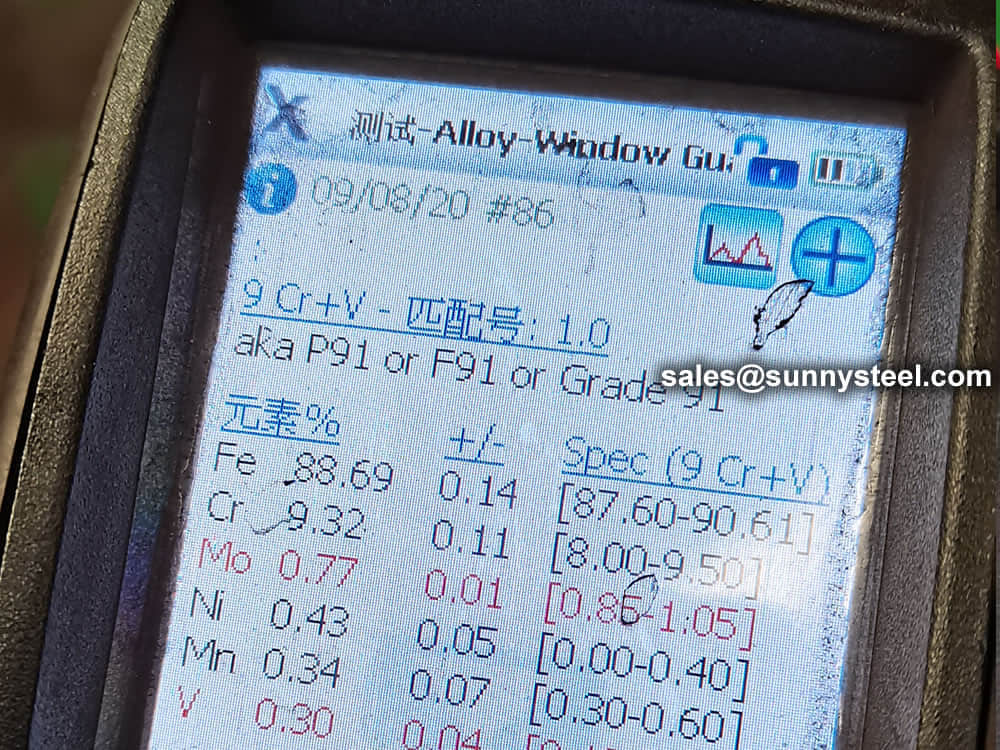

identification of the chemical composition of the metal used to manufacture the fitting. Uses PMI sensors, including X-ray fluorescence or optical emission spectrometry.

Steel pipe delivery status(condition): cold / hard (BK), cold / soft (BKW), after cold stress relief annealing (BKS), annealing (GBK), normalized (NBK).

| Term | Symbol | Explanation |

|---|---|---|

| Cold-finished/hard (cold-finished as-drawn) | BK | No heat treatment after the last cold-forming process. The tubes therefore have only low deformability. |

| Cold-finished/soft (lightly cold-worked) | BKW | After the last heat treatment there is a light finishing pass (cold drawing) With proper subsequent processing, the tube can be cold-formed (e.g. bent, expanded) within certain limits. |

| Annealed | GBK | After the final cold-forming process the tubes are annealed in a controlled atmosphere or under vacuum. |

| Normalized | NBK | The tubes are annealed above the upper transformation point in a controlled atmosphere or under vacuum. |

The general cold strip mills, volume should go through continuous annealing (CAPL unit) to eliminate cold hardening and rolling stress, or batch annealing reach the mechanical properties of the corresponding standard specifies. Cold rolled steel surface quality, appearance, dimensional accuracy better than hot-rolled plate, and right-rolled thin product thickness is about 0.18mm, so the majority of users favor.

Cold rolled steel coil substrate products deep processing of high value-added products. Such as electro-galvanized, hot dip galvanized, electro-galvanized fingerprint resistant, painted steel roll damping composite steel, PVC laminating steel plates, etc., so that the excellent quality of these products has a beautiful, high resistance to corrosion, has been widely used.

Cold rolled steel coil finishing after annealing, cut the head, tail, trimming, flattening, smooth, heavy volume, or longitudinal clipboard. Cold-rolled products are widely used in automobile manufacturing, household electrical appliances, instruments, switches, buildings, office furniture and other industries. Steel plate strapping package weight of 3 to 5 tons. Flat sub-volume typically 3 to 10 tons / volume. Coil diameter 6m.

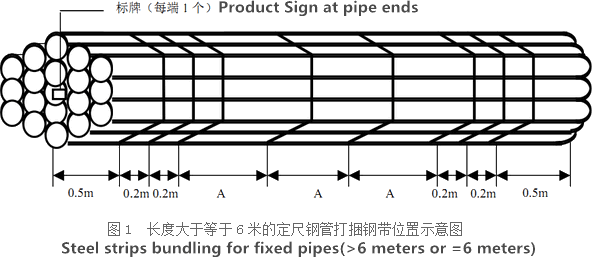

Bare packing/bundle packing/crate packing/wooden protection at the both sides of tubes and suitably protected for sea-worthly delivery or as requested.

There are probably hundreds of different methods for packing a pipe, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.

Our packing can meet any needs of the customers.

Commonly used alloying elements and their effects are listed in the table given below.

| Alloying Elements | Effect on the Properties |

|---|---|

| Chromium | Increases Resistance to corrosion and oxidation. Increases hardenability and wear resistance. Increases high temperature strength. |

| Nickel | Increases hardenability. Improves toughness. Increases impact strength at low temperatures. |

| Molybdenum | Increases hardenability, high temperature hardness, and wear resistance. Enhances the effects of other alloying elements. Eliminate temper brittleness in steels. Increases high temperature strength. |

| Manganese | Increases hardenability. Combines with sulfur to reduce its adverse effects. |

| Vanadium | Increases hardenability, high temperature hardness, and wear resistance. Improves fatigue resistance. |

| Titanium | Strongest carbide former. Added to stainless steel to prevent precipitation of chromium carbide. |

| Silicon | Removes oxygen in steel making. Improves toughness. Increases hardness ability |

| Boron | Increases hardenability. Produces fine grain size. |

| Aluminum | Forms nitride in nitriding steels. Produces fine grain size in casting. Removes oxygen in steel melting. |

| Cobalt | Increases heat and wear resistance. |

| Tungsten | Increases hardness at elevated temperatures. Refines grain size. |

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.