Welded Bellows Pump Connectors

Durable welded bellows connectors for reliable pump applications.

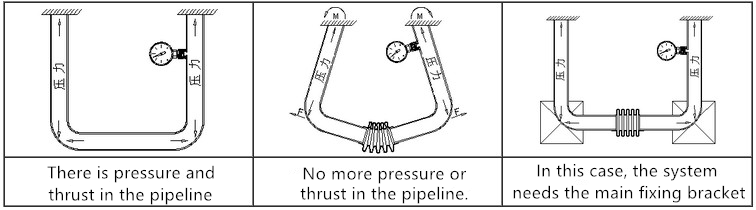

The metal expansion joint without tie rod is mainly used to compensate for axial displacement and has the ability to compensate for angular displacement, but it is generally not used to compensate for angular displacement.

These pipes are used in various industries where durability and longevity are crucial.

Download PDFThe metal expansion joint without tie rod belongs to a compensating element. The metal expansion joint without tie rod is mainly used to compensate for axial displacement and has the ability to compensate for angular displacement, but it is generally not used to compensate for angular displacement. Metal expansion bellows are compensating elements for thermal expansion and relative motion in pipes, vessels and machines. Absorption of axial, lateral, and angular displacement.

Axial movement is considered to be the elongation or compression of the pipe system on its longitudinal axis, which means that the total length of the expansion joint will extend or compress during the absorption movement. An axial expansion joint designed to absorb large motions can contain one, two or more bellows in one unit, and can also achieve greater motion by pretensioning or by installing multiple expansion joints on the pipe section. . Depending on the nominal diameter and length, the axial expansion joints are able to absorb small lateral and angular deviations as well as mounting tolerances. However, we recommend the use of the main function that should limit the axial expansion joint, otherwise its service life may be adversely affected.

The unlimited metal expansion joint can be used in a variety of applications and can be used over temperature, pressure and size.

The unlimited metal expansion joint uses the telescopic and offset of its main elastic element bellows to compensate the displacement of the pipeline. The compensation amount is large and the elasticity is good. The product is suitable for conveying seawater, fresh water, hot and cold water, drinking water and life. Sewage, crude oil, fuel oil, lubricating oil, refined oil, air, gas, etc.

The unlimited metal expansion joint is also called a shock absorbing corrugated bellow, a bellows, an expansion joint, or a telescopic joint. It consists of a bellows (an elastic element) that constitutes its working body, and accessories such as a joint and a flange. The unlimited metal expansion joint belongs to a compensating element.

| Nominal diameter DN |

Quantity of ripple | Pressure level(Mpa) | Effective area of corrugated tube (cm2) |

Maximum external diameter size (mm) |

Length | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.25 | 0.6 | 1 | 1.6 | 2.5 | Flange JDZ/F (mm) | Connection tube JDZ/F (mm) |

||||

| Axial compensation (mm),f911 degree N/ram | ||||||||||

| 32 | 8 | 25/21 | 22/26 | 20/26 | 18/63 | 15/98 | 16 | 110 | 160/250 | 264/210 |

| 16 | 50/11 | 46/14 | 41/14 | 36/32 | 31/47 | 220 | 224/291 | 316/320 | ||

| 40 | 8 | 25/28 | 22/44 | 20/44 | 18/89 | 15/106 | 23 | 130 | 164/259 | 269/260 |

| 16 | 50/14 | 46/22 | 41/22 | 36/45 | 31/55 | 240 | 230/304 | 319/400 | ||

| 50 | 8 | 25/30 | 22/51 | 20/70 | 18/70 | 15/138 | 37 | 150 | 172/276 | 282/230 |

| 16 | 50/16 | 46/26 | 41/35 | 36/35 | 31/70 | 260 | 240/342 | 347/450 | ||

| 65 | 8 | 33/28 | 30/35 | 26/44 | 22/55 | 19/68 | 55 | 170 | 315/294 | 300/260 |

| 12 | 42/16 | 38/22 | 38/32 | 34/40 | 29/50 | 280 | 260/334 | 340/470 | ||

| 80 | 8 | 40/20 | 36/26 | 34/33 | 28/41 | 24/54 | 81 | 200 | 240/338 | 344/260 |

| 10 | 53/14 | 49/17 | 49/21 | 43/26 | 38/33 | 230 | 270/368 | 374/300 | ||

| 100 | 8 | 45/47 | 45/60 | 40/75 | 35/93 | 29/117 | 121 | 220 | 235/317 | 323/280 |

| 10 | 76/26 | 74/32 | 64/40 | 57/50 | 49/63 | 260 | 305/381 | 387/320 | ||

| 125 | 6 | 48/38 | 42/47 | 38/59 | 34/74 | 29/92 | 180 | 250 | 282/314 | 316/320 |

| 8 | 85/23 | 77/29 | 66/36 | 58/45 | 50/56 | 290 | 382/386 | 388/360 | ||

| 150 | 6 | 49/42 | 44/50 | 40/62 | 34/78 | 29/97 | 257 | 250 | 282/339 | 338/320 |

| 8 | 79/34 | 71/43 | 64/51 | 54/59 | 46/65 | 290 | 356/399 | 402/360 | ||

| 200 | 6 | 52/49 | 46/55 | 42/68 | 38/78 | 34/111 | 479 | 300 | 280/348 | 348/370 |

| 8 | 73/31 | 65/44 | 59/52 | 53/58 | 48/78 | 340 | 340/402 | 402/420 | ||

| 250 | 6 | 72/30 | 63/34 | 59/42 | 52/45 | 47/55 | 769 | 300 | 315/379 | 415/420 |

| 8 | 108/16 | 97/21 | 87/35 | 79/39 | 71/47 | 360 | 393/459 | 493/460 | ||

| 300 | 6 | 72/51 | 65/55 | 59/59 | 52/65 | 47/71 | 1105 | 340 | 366/427 | 466/488 |

| 8 | 108/32 | 97/35 | 87/37 | 79/41 | 71/45 | 400 | 464/525 | 564/520 | ||

| 350 | 6 | 72/58 | 65/62 | 59/67 | 52/74 | 47/81 | 1307 | 340 | 397/452 | 497/480 |

| 8 | 108/38 | 97/41 | 87/44 | 79/48 | 71/47 | 420 | 509/564 | 609/540 | ||

| 400 | 6 | 72/54 | 65/58 | 59/62 | 52/68 | 47/75 | 1611 | 340 | 412/478 | 512/480 |

| 8 | 108/36 | 97/39 | 87/43 | 79/47 | 71/52 | 420 | 522/588 | 622/560 | ||

| 450 | 6 | 108/32 | 97/35 | 87/37 | 79/41 | 71/45 | 1972 | 340 | 403/498 | 503/500 |

| 8 | 162/20 | 145/22 | 131/23 | 118/25 | 106/28 | 450 | 503/658 | 603/590 | ||

| 500 | 6 | 108/59 | 97/64 | 87/68 | 79/75 | 71/82 | 2445 | 340 | 431/523 | 531/500 |

| 8 | 162/34 | 145/37 | 131/39 | 118/43 | 106/48 | 450 | 531/665 | 631/600 | ||

| 600 | 6 | 108/74 | 97/80 | 87/85 | 79/94 | 71/103 | 3534 | 380 | 478/548 | 578/540 |

| 8 | 162/42 | 145/45 | 131/49 | 118/53 | 106/60 | 658/679 | 758/640 | |||

| 700 | 4 | 108/67 | 97/72 | 87/77 | 79/85 | 71/103 | 4717 | 1110 | 490 | 550 |

| 6 | 162/42 | 145/45 | 131/49 | 118/53 | 106/60 | 690 | 670 | |||

| 800 | 4 | 120/88 | 102/95 | 102/102 | 94/112 | 71/95 | 5822 | 1265 | 502 | 560 |

| 6 | 183/67 | 164/72 | 156/77 | 144/85 | 106/60 | 610 | 600 | |||

| 900 | 4 | 120/84 | 108/90 | 102/97 | 94/107 | 82/123 | 7620 | 1186 | 620 | |

| 6 | 183/60 | 164/65 | 156/69 | 144/76 | 125/93 | 720 | ||||

| 1000 | 4 | 120/91 | 108/98 | 102/105 | 94/116 | 82/117 | 9043 | 1286 | 690 | |

| 6 | 183/59 | 164/65 | 156/71 | 144/81 | 125/84 | 790 | ||||

Our team of experienced sales specialists proudly partners with gas and chemical processors, power generation plants, oil refineries, and related industries to offer piping components and value-added services.

Q: How can you guarantee the quality or any warranty?

A: Check the specification, material and appearance before delivery, and approve the delivery after qualified.

B: Support third-party inspection.

Q: What can we do for you?

A: we support OEM/ODM,we can provide drawings,technical support,installation maintenance.

Q: Can you provide samples?

A: Yes, we generally provide samples with a diameter of 100 or less, and you need to bear the freight of the samples

Q:What information do I need to provide if I want an accurate quote.

A: Please confirm the product, material, working pressure, connection method, flange standard, medium and quantity.

Q: Do you accept small quantity order?

A: Of course we do.

Q:what are your payment term?

A: After receiving T/T 30% payment, start production; Remaining 70% paid before delivery

Q: Where is your nearest loading port?

A: Shanghai, Qingdao or Tianjin, China.

Q: When is your shipping and delivery time?

A: By sea or air. Normally 7 to 14 Days for delivery, according to your order quantity.

An expansion joint is a useful component in an infinite number of applications. Metal expansion joint assemblies are commonly used for all kinds of industries and applications including:

Expansion joints are often installed near boilers, heat exchangers, pumps, turbines, condensers, engines and in long pipe systems or pipe ducts.

Expansion joints come in a wide variety of designs. Some of them are standard and some are customised as per client requirements.

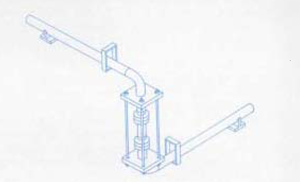

Although their design may vary significantly, all expansion joints are nevertheless composed from some of the following components, all with one or more specific functionalities: bellows, welding ends, flanges, hinges, tie-rods, spherical washers, wire mesh, insulation, inner sleeve, external cover, elbow and/or ring reinforcement/equalizing rings.

In general, there are fabric, metallic, and rubber expansion joints.

In a piping system a Expansion joints alternately known as Bellows are like sealed springs. Sealed because it is required to contain the fluid pressure which is flowing through it and spring because it is required to respond to the movement of the connected piping without offering appreciable stiffness to the piping system.

The Bellows are generally employed in a piping system in one of the following situations:

An expansion joint or movement joint is an assembly designed to safely absorb the heat-induced expansion and contraction of construction materials, to absorb vibration, to hold parts together, or to allow movement due to ground settlement or earthquakes.

They are commonly found between sections of buildings, bridges, sidewalks, railway tracks, piping systems, ships, and other structures.

Expansion joints – sometimes called expansion bellows, flexible joints or Expansion joint – are devices that comprise of a flexible element known as the bellows membrane that is fitted to end connections that are best suited to the pipework they are to be installed in.

Most bellows membranes are manufactured from stainless steel and are made up of a series of convolutions manufactured to withstand the pressure of the system but also must be suitable to accept the movements for which they are designed. The bellows membrane comprises of a series of convolutions designed to withstand the internal pressures of the system, but at the same time flexible enough to accept axial, lateral and angular deflections.

The joint needs to be a highly resistant nature so it’s necessary to make sure that it’s far thicker than you’d expect. In turn, this slows down any effects of potential corrosion as although it may be affected by the elements over time, it will still retain its density.

Expansion joints are required in large ducted air systems to allow fixed pieces of piping to be largely free of stress as thermal expansion occurs.

Bends in elbows also can accommodate this.

Expansion joints also isolate pieces of equipment such as fans from the rigid ductwork thereby reducing vibration to the ductwork as well as allowing the fan to “grow” as it comes up to the operating air system temperature without putting stress on the fan or the fixed portions of ductwork.

An expansion joint is designed to allow deflection in the axial(compression) or laterally (shear) or angular (bending) deflections. Expansion joints can be non-metallic or metallic (often called bellows type). Non-metallic can be a single ply of rubberized material or a composite made of multiple layers of heat and erosion resistant flexible material.

Typical layers are: outer cover to act a gas seal, a corrosion resistant material such as Teflon, a layer of fiberglass to act as an insulator and to add durability, several layers of insulation to ensure that the heat transfer from the flue gas is reduced to the required temperature and an inside layer.

A bellows is made up of a series of one or more convolutions of metal to allow the axial, lateral or angular deflection required.

Tied universal expansion joints are frequently used to absorb lateral deflection in a “Z” bend configuration. The expansion joint absorbs the thermal movement ol horizontal pipelines as lateral defleclion. This can be accomplished in a single plane or three plane configuration. In a three plane “Z ” bend the horizontal pipes may lie at any angle in the horizontal plane since the tied universal expansion joint can absorb lateral deflection in any direction.

Expansion joints are used in all kinds of different sectors and in a huge range of different industrial contexts.

Specific industries that use expansion joints include the Energy sector such as nuclear power plants and district heating schemes.

Essentially, wherever there is a need to control pipework movement expansion joints are required. They are used in factories and power plants wherever thermal expansion needs to be controlled, such as pipelines that connect with condensers or power turbines. They are used in oil and fuel gas applications.

The Petrochemical industry on oil refineries, pumping stations and oil rigs.

Civil engineering, waste management, sewage treatment, recycling, water treatment, aerospace, aviation, defence, the automotive industry, agriculture, mining, metals manufacturing, food and dairy manufacturing and packaging, and so on.

Double flanged joints for secure and reliable pipe expansion compensation.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.