Butt Weld Pipe Fittings

Precision engineered butt weld fittings for seamless pipe connections.

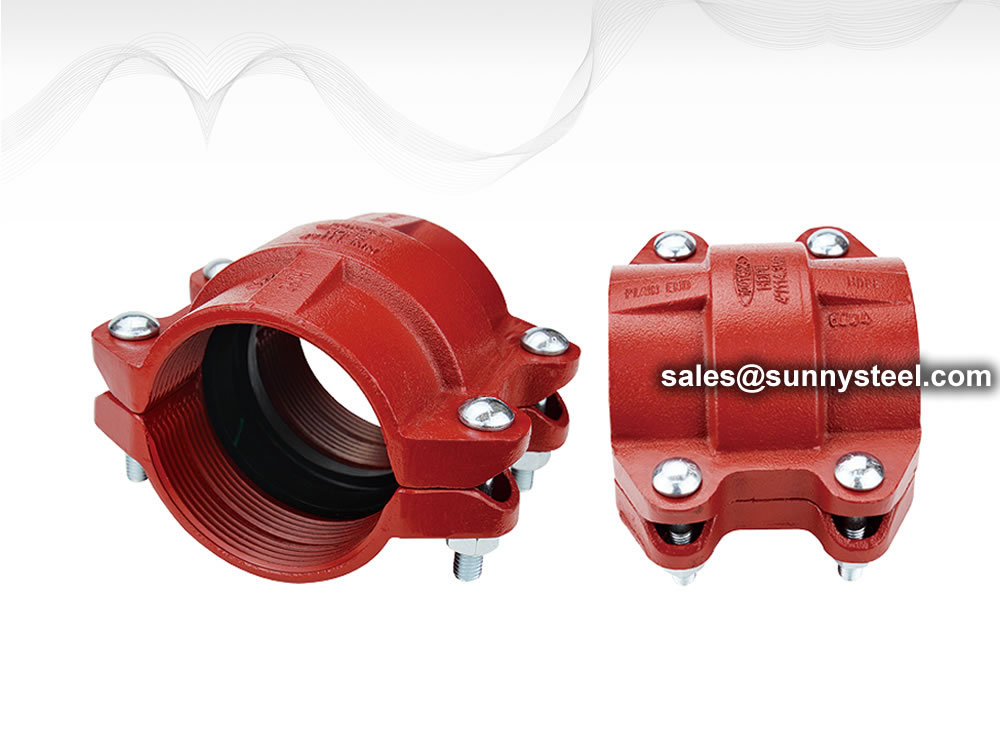

Mechanical HDPE coupling offers a cost-effective, fast and easy way to join high density polyethylene pipe and fittings.

Our tongue and groove design rigid coupling can be used where rigidity is required.HDPE Transition Coupling is a cost effective, easy to assemble, mechanical joint intended to connect HDPE pipe to standard weight roll or cut grooved steel pipe, lightweight roll grooved pipe, or grooved-end fittings and valves.

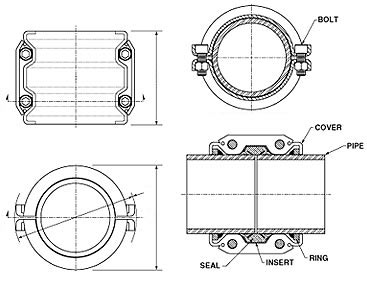

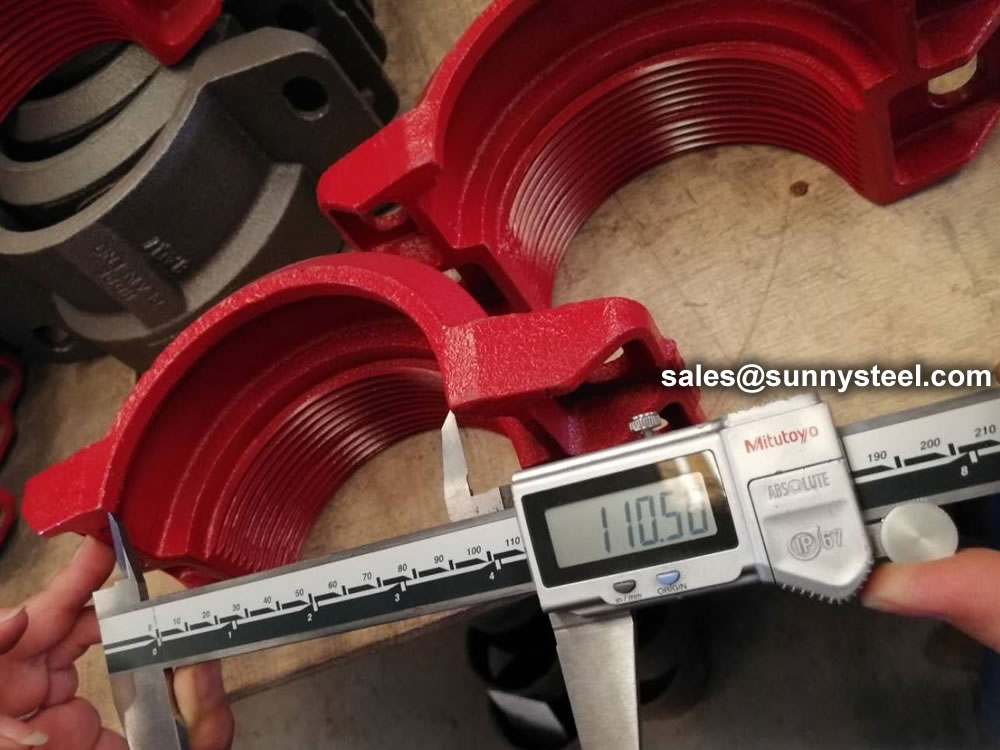

Each coupling uses four bolts to drive sharply machined teeth into the outside of the HDPE pipe and engages a keyed section into the grooved steel pipe or fitting. When the teeth effectively grip into the pipe, it provides a secure and rigid mechanical connection with pressure capabilities exceeding that of the HDPE pipe itself without the need for costly fusion equipment.

Besides being used as an important pipe fitting, couplings are also used in the following:

Pipe couplings are primarily used to join two or more sections of pipes together. They provide a secure and leak-proof connection, ensuring the continuity of fluid or gas flow in the piping system.

Couplings are often used for pipe repair and maintenance. They allow for the quick and easy replacement of damaged or corroded sections of pipe without the need for extensive cutting or welding.

Parts of Pipe Coupling

Some important features of couplings are as follows:

Pipe couplings are made of various materials and the buyers should always consider the material used for making them. Some of the materials used for making couplings are:

Any type of packing is available according to customer need to worldwide destinations.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.