Butt Weld Pipe Fittings

Precision engineered butt weld fittings for seamless pipe connections.

Coupling fittings are used for fluid conduits in which each end portion of two tubes to be connected is provided with a swaged-on adapter carrying the necessary means to connect or disconnect the tubes without disturbing the swaged-on adapter.

Tubing coupling mainly aims to solve the existing couplings easily generated due to fatigue fracture stress concentration problems.

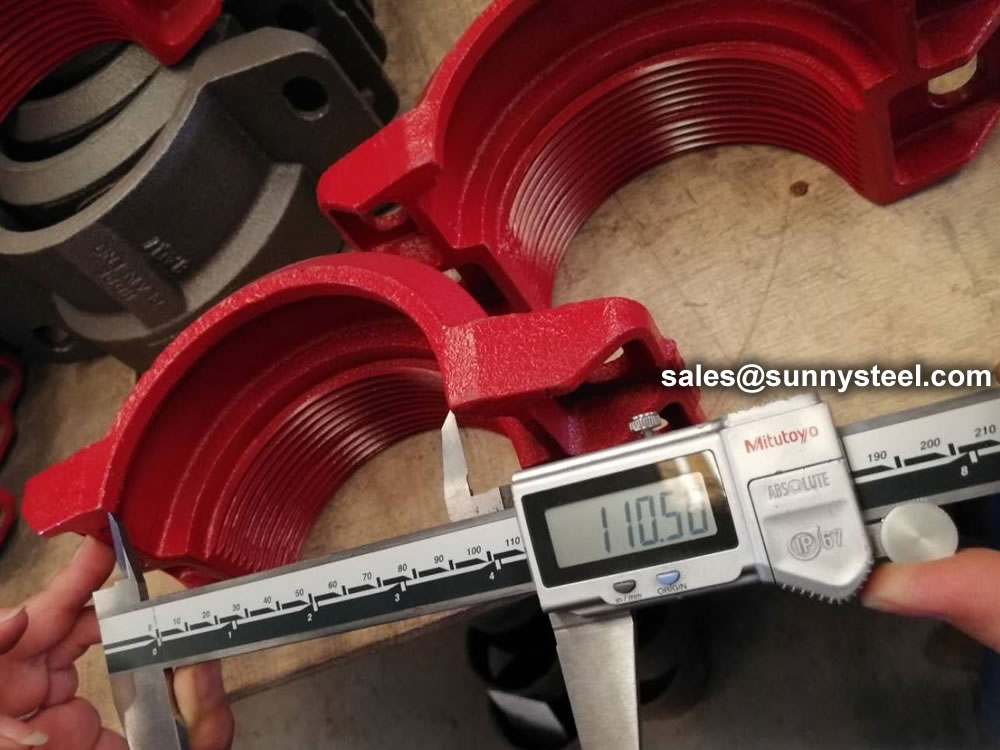

Pipe couplings are highly demanded in the pipe fitting market. Pipe couplings are fittings that help to extend or terminate pipe runs. These fittings are also used to change pipe size. Couplings extend a run by joining two lengths of pipe. They are known as reduced coupling if they are used to connect pipes of different sizes. Couplings are also known as repair couplings. These couplings are without stops or ridges and they can be fixed anywhere along the pipe length for preventing leak of any kind.

Full Coupling fittings

Half Coupling fittings

Reducer Coupling

Material: ASTM A105, F304, F316, F304L, F316L, A182, F11, F22, and F91

Pressure: 2000LBS, 3000LBS, 6000LBS, 9000LBS

Size: from 1/4 to 4 inches

Standard: ANSI B16.9/B16.28 and MSS SP-43/SP-75

Connection ends: butt welded, threaded

Thread types: NU, EU, STC, LTC and BTC

Surface treatment:Shot blasted, rust-proof black oil

Packing: Plywood Case/ Pallet/ other

Any type of packing is available according to customer need to worldwide destinations.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.