Bimetallic Composite Pipe

Read more

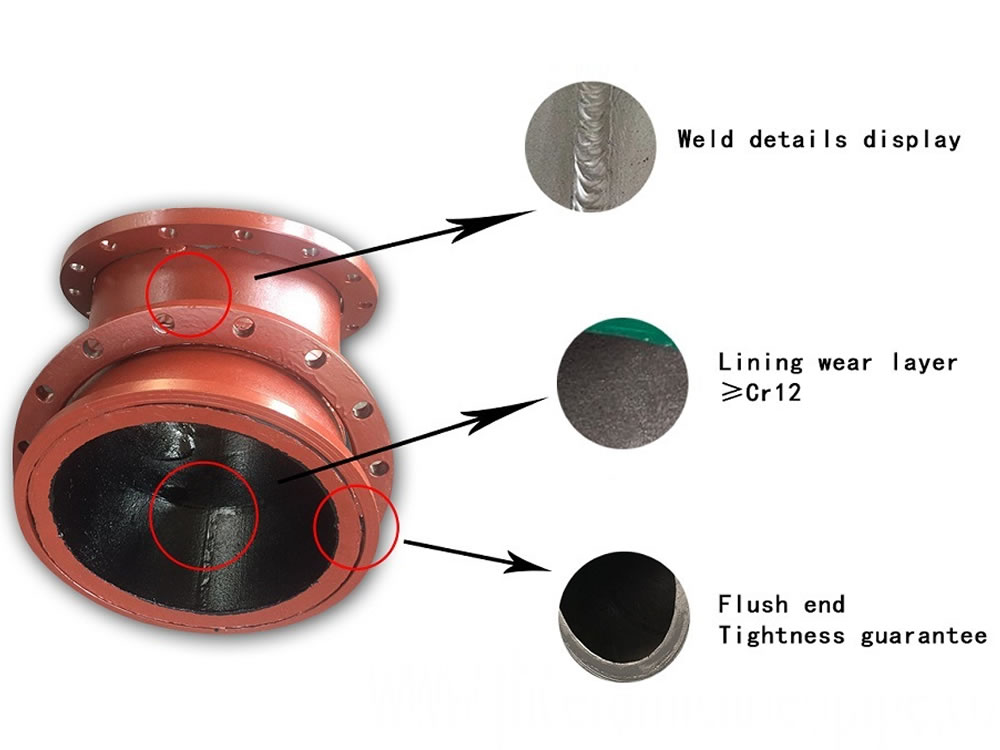

The Bimetal clad pipe bend has inner and outer double layers of metal, the inner lining is made of wear-resistant cast iron, the inner lining material has good wear resistance and corrosion resistance, and the outer layer material has high mechanical strength and high impact resistance.

Download PDFIt not only satisfies the special requirements, but also saves costs.

In a clad line pipe, the corrosion-resistant alloy forms a complete barrier layer on the internal surface of carbon or low-alloy steel pipe (usually referred to as the “backing steel”). In general, use of clad or bi-metal-lined pipe allows the economic use of expensive CRA materials,It has been widely concerned and used in many other fields abroad.

The wear resistance of the high-chromium bimetallic lined pipe is at least many times that of ordinary steel pipes. The bimetallic composite steel pipe has inner and outer double layers of metal, the inner lining is made of wear-resistant cast iron, the inner lining material has good wear resistance and corrosion resistance, and the outer layer material has high mechanical strength and high impact resistance. The lost foam composite process is directly adopted, and the metallurgical composite is formed by casting, which is safe and reliable to use.

Lined high-chromium bimetallic composite pipes include high-chromium bimetallic composite straight pipes lined, high-chromium bimetallic composite elbows lined, high-chromium bimetallic composite tee lined, Lined with high-chromium bimetal composite multi-pass, lined with high-chromium bi-metal composite reducer, lined with high-chromium bi-metal composite flash buffer device, etc.

Bimetal wear resistant products including: double metal wear-resisting straight pipe and double metal wear-resisting bend, double metal wear tee, double metal wear resistance reducer adopts the pipe fittings such as vacuum suction casting composite process, its advanced technology, effectively solve the problem of the bent pipe cannot be composite, bending and other various special-shaped pipe can do the whole compound, don’t change the material flow in the pipe bending trajectory, reduce resistance material conveying.

The outer wall of the centrifugal pipe is made of carbon steel, which ensures that the bimetal wear-resistant pipe has high mechanical strength and impact resistance.The inner lining wear resistance layer adopts the anti-wear alloy steel series independently developed by our company. The steel mainly adds alloy such as cr-ni-mo-cu-re and so on. Through the tempering heat treatment process, the alloy steel has strong wear resistance and corrosion resistance, high mechanical strength and impact resistance.

The whole set of process of our factory is the first in China, which fills the blank of anti-corrosion and wear-resistant industrial pipeline in China and has reached the international advanced level. It has been widely used in mining, metallurgy, coal, electric power and other industries, and is an ideal wear-resistant pipeline.

| Flexure Strength MN/㎡ |

Tensile Strength MN/㎡ |

Elongation % |

Cross Section Stretch Ratio % |

Impact Toughness J/c㎡ |

Hardness of Wearable Layer HRC |

Hydrostatic Testing Pressure Mpa |

|---|---|---|---|---|---|---|

| >610 | >700 | 5 | 5.1 | >15 | >38 | 5.6-12.9 |

| Standard | Item | Grade | Chemical composition (%) | Tensile requirements | Hardness(HB) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | Thickness(mm) | Tensile strength(Mpa) | Elongation(%) | Heat treatment | ||||

| GB | 8263 | KmTBNi4-Cr2-DT | 2.7-3.2 | 0.3-0.8 | 0.3-0.8 | ≦0.15 | ≦0.1 | 3.0-5.0 | 2.0-3.0 | 0.0-1.0 | - | - | - | - | - | - |

| ASTM | A532 | I BNiCr-LC | 2.4-3.0 | ≦0.8 | ≦2.0 | ≦0.3 | ≦0.15 | 3.3-5.0 | 1.4-4.0 | ≦1.0 | - | ≧200 | - | - | - | ≦550 |

| DIN | 1695 | G-X260-NiCr42 | 2.6-2.9 | 0.2-0.8 | 0.3-0.7 | - | - | 3.5-5.0 | 1.4-2.4 | ≦0.5 | - | - | ≧320 | - | - | ≦500 |

| GB | 8263 | KmTBNi4-Cr2-GT | 3.2-3.6 | 0.3-0.8 | 0.3-0.8 | ≦0.15 | ≦0.1 | 3.0-5.0 | 2.0-3.0 | 0.0-1.0 | - | - | - | - | - | - |

| ASTM | A532 | I ANCr-HC | 2.8-3.6 | ≦0.8 | ≦1.3 | ≦0.3 | ≦0.15 | 3.3-5.0 | 1.4-4.0 | ≦1.0 | - | ≧200 | - | - | - | ≦550 |

| DIN | 1695 | G-X330-NiCr42 | 3.0-3.6 | 0.2-0.8 | 0.3-0.7 | - | - | 3.3-5.0 | 1.4-2.4 | ≦0.5 | - | - | ≧280 | - | - | ≦690 |

| GB | 8263 | KmTBCr9-Ni5Si2 | 2.5-3.6 | 1.5-2.2 | 0.3-0.8 | ≦0.15 | ≦0.1 | 4.5-6.5 | 8.0-10.0 | 0.0-1.0 | - | - | - | - | - | - |

| ASTM | A532 | I DNiHCr | 2.5-3.6 | ≦2.0 | ≦2.0 | ≦0.1 | ≦0.15 | 4.5-7.0 | 7.0-11.0 | ≦1.5 | - | ≧300 | - | - | - | ≦500 |

| DIN | 1695 | G-X300Cr-NSi952 | 2.5-3.5 | 1.5-2.2 | 0.3-0.7 | - | - | 4.5-6.5 | 8.0-10.0 | ≦0.5 | - | - | 500-600 | - | - | ≦690 |

| GB | 8263 | KmTBCr15-Mo2-GT | 2.8-3.5 | ≦1.0 | 0.5-1.0 | ≦0.1 | ≦0.06 | 0.0-1.0 | 13.0-18.0 | 0.5-3.0 | 0.0-1.2 | - | - | - | - | - |

| ASTM | A532 | ⅡB15%Cr-Mo-HC | 2.0-3.0 | ≦1.5 | ≦2.0 | ≦0.1 | ≦0.06 | ≦2.5 | 14.0-18.0 | 1.0-3.0 | ≦1.2 | ≧75 | - | - | H | ≦600 |

| DIN | 1695 | G-X300-CrMo153 | 2.3-3.6 | 0.2-0.8 | 0.5-1.0 | - | - | ≦0.7 | 14.0-17.0 | 1.0-3.0 | ≦1.2 | - | ≧450 | ≦690 | H | - |

| ASTM | A532 | Ⅱ020%-CrMo-LC | 2.0-3.3 | 1.0-2.2 | ≦2.0 | ≦0.1 | ≦0.06 | ≦1.5 | 18.0-23.0 | ≦2.0 | ≦1.2 | ≧200 | - | - | H | ≦600 |

| DIN | 1695 | G-X260Cr-MoNi2021 | 2.3-2.9 | 0.2-0.3 | 0.5-1.0 | - | - | 0.8-1.2 | 18.0-22.0 | 1.4-2.0 | - | - | ≧450 | - | H | ≦690 |

| GB | 8263 | KmTBCr20-Mo2Cu1 | 2.0-3.0 | ≦1.0 | 0.5-1.0 | ≦0.1 | ≦0.06 | 0.0-1.5 | 18.0-22.0 | 1.5-2.5 | 0.8-1.2 | - | - | - | - | - |

| ASTM | A532 | ⅡA-25%Cr | 2.0-3.0 | ≦1.5 | ≦2.0 | ≦0.1 | ≦0.06 | ≦2.5 | 23.0-30.0 | ≦3.0 | ≦1.2 | ≧200 | - | - | - | ≦600 |

| DIN | 1695 | G-X260-Cr27 | 2.3-2.9 | 0.5-1.5 | 0.5-1.5 | - | - | ≦1.2 | 24.0-28.0 | ≦1.0 | - | - | ≧560 | - | - | ≦690 |

| GB | 8263 | KmTBCr26 | 2.3-3.0 | ≦1.0 | 0.5-1.0 | ≦0.1 | ≦0.06 | 0.0-1.5 | 23.0-28.0 | 0.0-1.0 | 0.0-2.0 | - | - | - | - | - |

| ASTM | A532 | Ⅲ A-25%Cr | 2.0-3.3 | ≦1.0 | ≦2.0 | ≦0.1 | ≦0.06 | ≦2.5 | 23.0-30.0 | ≦1.5 | ≦1.2 | ≧200 | - | - | H | ≦600 |

| DIN | 1695 | G-X300Cr-Mo271 | 3.0-3.5 | 0.2-1.0 | 0.5-1.0 | - | - | - | 23.0-28.0 | 1.0-2.0 | ≦1.2 | - | ≧450 | - | H | ≦690 |

Bimetal wear resistant pipe adopts centrifugal casting technology in the production process of straight pipe.

This technology is to fuse and shape both metals in liquid state, realizing the purpose of real metallurgical bonding. The shear strength of the binding layer is higher than that of the metal itself, and completely realizes the mechanical complementarity between base layer and wear resistant layer.

Bimetal wear resistant pipe, including: double metal wear-resisting straight pipe and double metal wear-resisting bend, double metal wear tee, double metal wear resistance reducer adopts the pipe fittings such as vacuum suction casting composite process, its advanced technology, effectively solve the problem of the bent pipe cannot be composite, bending and other various special-shaped pipe can do the whole compound, don't change the material flow in the pipe bending trajectory, reduce resistance material conveying.

The outer wall of the centrifugal pipe is made of carbon steel, which ensures that the bimetal wear-resistant pipe has high mechanical strength and impact resistance.The inner lining wear resistance layer adopts the anti-wear alloy steel series independently developed by our company. The steel mainly adds alloy such as cr-ni-mo-cu-re and so on. Through the tempering heat treatment process, the alloy steel has strong wear resistance and corrosion resistance, high mechanical strength and impact resistance.

The whole set of process of our company is the first in China, which fills the blank of anti-corrosion and wear-resistant industrial pipeline in China and has reached the international advanced level. It has been widely used in mining, metallurgy, coal, electric power and other industries, and is an ideal wear-resistant pipeline.

The base material is carbon steel or low alloy steel. Clad pipes comply with the most stringent requirements of strength and corrosion resistance. The carbon steel outer pipe (backing steel or base metal) complies with the static requirements of strength and durability whereas the high alloyed inside pipe provides protection against corrosion.

Because oil and natural gas contains a large amount of corrosive media such as hydrogen sulfide, carbon dioxide and chloride ions, especially the content of corrosive components in the oil and gas medium before pipeline purification in the seabed oil and gas field is high, and some even require heat transfer, and internal corrosion problems are very prominent.

The use of stainless steel or corrosion-resistant alloys in large quantities is not economical. Double metal clad pipes are a good choice.

The bimetal clad pipe structure uses a corrosion-resistant alloy tube (stainless steel or corrosion-resistant alloy) as the inner liner (wall thickness 0.5-3mm) to contact the corrosive medium and carbon steel or low-alloy steel as the outer base pipe to withstand the pressure. low. Generally, the double-metal clad pipe contains 316L austenite stainless steel as the inner liner in the case of containing CO2 medium, and 2205 and 2505 duplex stainless steel can be used as the medium containing CO2 + small amount of chloride, when H2S+CO2 is contained. + Chloride, the inner liner should be 028, G3, INCONEL625 and Inconel825 nickel-base or iron-nickel alloy, in order to ensure the corrosion resistance of the pipeline, but also can choose the titanium alloy and other materials with excellent corrosion resistance as lining. The outer layer material is usually API 5L X42, X50, X60, X70, ASTM-A106GB and A335-P22 and other materials, so as to ensure the strength of the pipeline.

Choosing stainless steel such as Incoloy625 and Incoloy825 for inner tubes to ensure the corrosion resistance of the pipe. The outer pipe are usually X42, X50, X60, X70, A335-P22 and other materials to ensure the strength of the pipeline. The American Petroleum Association (API) has developed the standard for composite pipes for pipelines,with the serial number API 5LD:Cr-Mo steel,super 13Cr, G3, C028 and other oil well tubes and the nickel-base alloy cladding tubes such as 825, 028.

The steel tube for superheater should have high temperature strength under the condition of 650 and 35 MPa steam,excellent surface temperature and corrosion resistance, and inner surface resistance to water vapor oxidation.

Japan Sumitomo metal company choose SUS310S, 35Cr-55Ni, 40Cr-55Ni as outer base tube and 17-14CuMo,Alloy800Has the inner tube,developed super supercritical boiler superheater cladding pipe.

Sandvik,a Sweden Steel Corp successfully developed carbon steel as an inner pipe and Sanicro28 steel with good corrosion resistance as outer pipe. The cladding steel pipe made by Sandvik does not need any change in the boiler structure design and can be used directly.

Cladding steel tube for waste incinerator.The outer tube can be made of Sanicro65 alloy, and the inner pipe may be carbon steel or chromium molybdenum steel with resistance to stress corrosion cracking.Europe and the United States have used 2 million meter composite steel pipe since the first installation cladding pipe incinerator superheater and water wall tubes in the 1971.

Cladding steel pipe used for heat exchanger should also have good thermal conductivity and a certain strength and corrosion resistance.

Sandvik manufactured cladding pipe with high alloy nickel chromium alloy 800 as the inner tube and the low-alloy steel ASTM A213 Ti2 as the outer pipe.NKK company from Japan made cladding pipe with API 5L-16MnV steel as its outer pipe and NIC42 steel as inner pipe.

A Japan company have made cladding steel pipe with SUS316L corrosion resistant steel for outer pipe,Stellite No12 alloy for inner pipe,after 4 years is still new.They has also been well applied in the pneumatic conveying pipe of other micro powder particles, and the demand is increasing.

Inner pipe:Nickel, Titanium stainless steel or Copper alloy.

Outer pipe:Carbon steel or low alloy corrosion resistant steel.

Cladding pipe used for marine environment made by Japan's Kawasaki is widely used as marine heat exchanger tube and seawater desalination of seawater intake pipe.

Cold, hot water pipes, direct drinking water pipes, heating, solar energy, ground source heat pump; civil construction water supply pipes, water distribution trunk; air conditioning circulation pipe, fine decoration high-grade commercial housing water pipes.

Oil and gas pipeline, oil and gas wells casing, sewage return pipe; chemical heat exchanger tube bundle; power desalination water, desulfurization pipeline and other metallurgy, desalination, medicine and chemical industry, sewage treatment, new energy, food processing and other industries.

High chromium cast iron is the third generation of white cast iron developed from ordinary white cast iron and hard nickel cast iron.

The bimetal wear-resistant tube inner wall KMTBCr28 has stable quality and good comprehensive performance. Adding a certain amount of rare earth elements can improve the alloy quality of steel, refine the grain and form a protective film on the surface.A certain amount of Mo was added to make the alloy have certain antioxidant effect and increase service life at high temperature.A certain amount of boron carbide can be added to control the hardness in the range of HRC45 ~ 65, and solve the contradiction between the hardness and weldability of wear-resistant steel.

The inner and outer surface of bimetal wear-resistant elbow should be smooth and clean, without burrs, burrs, cracks, loose, pores or bubbles;The inner wall of the wear-resisting elbow should be smooth without accumulated powder.The bend should have good thermal shock resistance. When there is a sharp change in temperature or welding connection, the inner layer of the wear-resistant pipe will not break and spalling due to the expansion or contraction of the inner layer.The dimensional deviation shall meet the requirements of product drawings and order, agreement, and shall meet the provisions of GB3092, GB8162 and GB8163 without special requirements.The thickness deviation of lining is + / – 1.2mm.

A bimetal clad pipe is a composite pipe that consists of two different materials metallurgically bonded together. It typically comprises an inner layer made of a corrosion-resistant or wear-resistant material and an outer layer made of a structurally sound material.

A bimetal or thermostatic metal is a sheet or strip of two or more composite materials having different coefficients of linear thermal expansion bonded by riveting, brazing or welding.

KmTBCr28 has the main elements of Chrome 28%, low Carbon with hardness of 430 in Brinell. KmTBCr28 is a corrosion resistant white iron suitable for low pH corrosion duties, where erosive wear is also a problem.

Pipe cladding is the process of covering a pipe with cladding material.

This acts as protection from problems such as wear, abrasion, corrosion, impact, etc.

Pipe cladding refers to the process of applying a protective layer or coating on the outer surface of a pipe to enhance its durability, resistance to corrosion, wear, and other environmental factors. It involves bonding a different material, typically a corrosion-resistant alloy or a high-strength metal, onto the base pipe material.

Pipe cladding is commonly used in industries such as oil and gas, chemical processing, power generation, and water treatment, where pipes are exposed to harsh conditions and corrosive substances. The cladding material acts as a barrier, protecting the base pipe from corrosion, erosion, and other forms of damage.

There are several methods used for pipe cladding, including:

Weld-overlay cladding: In this method, a layer of cladding material is deposited onto the base pipe through welding. Various welding processes such as manual metal arc welding (MMA), gas tungsten arc welding (GTAW), or submerged arc welding (SAW) can be used depending on the cladding material and pipe size.

Explosion cladding: This technique involves using explosive energy to bond two materials together. The cladding material is generally in the form of a sheet or plate, which is explosively welded onto the base pipe.

Mechanical cladding: This method includes processes such as roll bonding and diffusion bonding. It involves mechanically bonding the cladding material onto the base pipe through pressure or heat, without the use of welding.

Pipe cladding provides several benefits, including increased resistance to corrosion, abrasion, chemicals, and high temperatures. It helps extend the lifespan of pipes, reduce maintenance costs, and improve overall performance and reliability in demanding industrial applications.

Bimetal clad pipes are manufactured using various processes, such as explosive welding, roll bonding, or vacuum diffusion bonding. These methods ensure a strong metallurgical bond between the two layers, creating a durable and reliable composite pipe.

Yes,

Bimetal clad pipes can be tailor-made to suit specific application needs. The choice of materials, dimensions, and shapes can be adjusted to meet the demands of different industries and operating conditions.

Yes,

bimetal clad pipes are designed to be easily installed using standard pipe joining techniques like welding, flanges, or mechanical couplings. Once installed, they require minimal maintenance due to their high wear and corrosion resistance properties.

Selecting the right bimetal clad pipe involves considering factors such as the conveyed material's corrosiveness and abrasiveness, operating temperature, pressure, and pipe dimensions. Consult with experienced suppliers or manufacturers to choose the most appropriate solution for your specific needs.

Yes,

Bimetal clad pipes can be designed to withstand high-temperature environments, depending on the materials selected for the inner and outer layers. Specialized materials and manufacturing techniques may be employed to ensure their stability and performance at elevated temperatures.

An axial fan is a type of fan that causes gas to flow through it in an axial direction, parallel to the shaft about which the blades rotate. The flow is axial at entry and exit. The fan is designed to produce a pressure difference, and hence force, to cause a flow through the fan.

(1) Centrifugal casting technology enables the molten steel to solidify and form under the gravity condition, which is dozens of times higher than conventional casting. It solves the problem of loose inside the casting tube billet, has high metal density, and has good discharge and exhaust effect.

(2)The size accuracy of centrifugal cast pipe is high and the wall thickness is even, which provides a favorable guarantee for the size accuracy of subsequent processed products.

(3)Centrifugal casting process has high flexibility for the production of steel pipes of small batch, multiple varieties and specifications, high quality and high value-added steel.

CRA basically means corrosion resistant alloy.

It’s a material that is built for cladding because its main purpose is to enhance a pipe’s resistance to corrosion.

Pipe elbow cladding is the process of applying a cladding material to elbow pipes.

It’s done on a more careful manner than the usual.

This is because elbow pipes can change throughout the entirety of the process.

Particularly, the process of pipe cladding benefits the oil and gas industry the most.

However, it can also be used by other industries such as:

Pipe lining is the process of prolonging the lifespan of pipes.

It can also be used, however, to restore a pipe from natural damages such as:

Pipe lining and pipe cladding are processes that are far from each other.

Lining is the process of mechanically bonding materials to pipes for restoration. Some of the uses of pipe lining include:

Cladding is the procedure of metallurgical bonding of clad materials to pipes. Some of the major uses of pipe cladding include:

There are a lot of companies that utilize state-of-the-art pipe cladding equipment.

We have cutting-edge technology that can complete projects ahead of time.

Some of the most notable features that our pipe cladding equipment have include:

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.