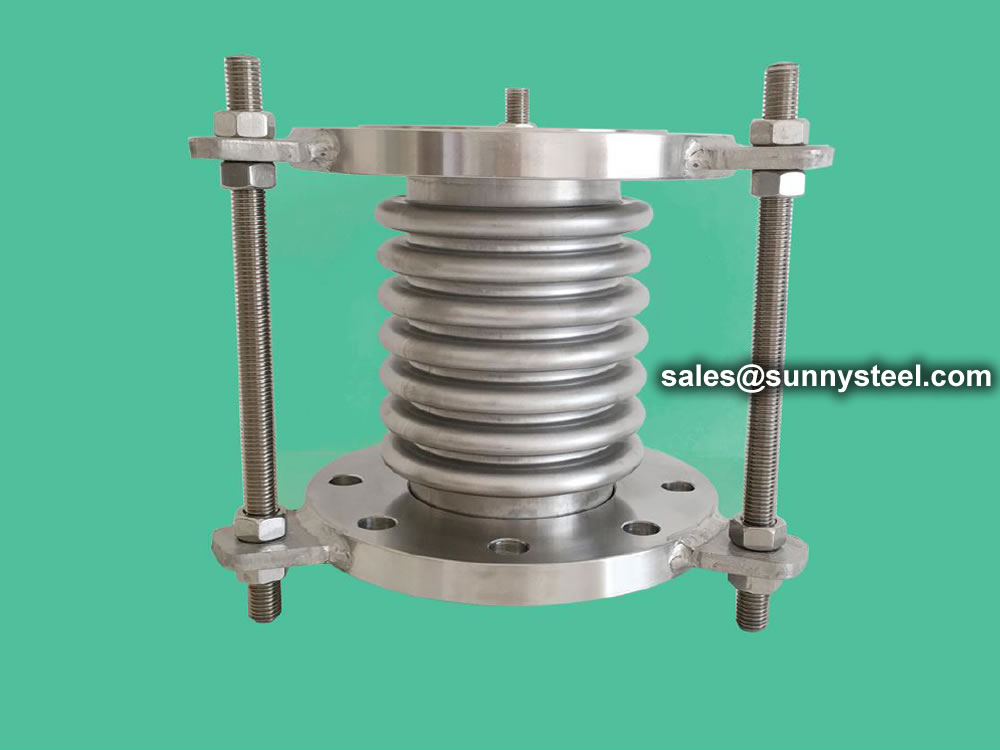

Bellows Expansion Joints are great for accommodating axial, lateral and angular movements for a wide array of piping applications.

Download PDF

Expansion bellows are also known as metal expansion joints and, as the name suggests, they help piping systems to contract and expand as a result of temperature changes. When pipelines are exposed to extreme temperatures, they either expand or contract depending on how high or low the temperature gets. This is where expansion bellows come in. Without expansion joints, pipelines would be subject to extreme stress and risk bursting due to pressure build-up, but a good quality expansion joint can easily handle thermal expansion while reducing the risk of failure. Expansion bellows also help with problems such as vibration, pressure surges and irregular movement caused by other mechanical components, making them an all-in-one component to secure pipelines and maintain their integrity and functionality.

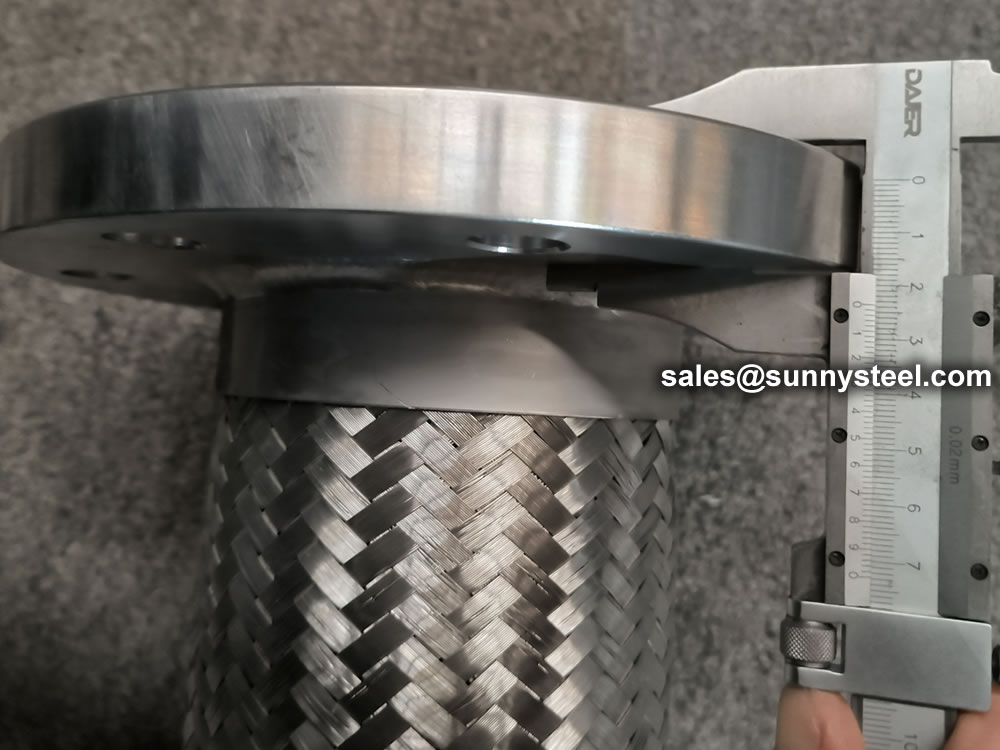

Expansion bellows are flexible connectors that help absorb thermal expansion, vibration and abnormal mechanical movement in pipelines, vessels and machinery. These bellows are made from durable materials such as stainless steel and nickel alloys that can withstand high pressures and temperatures. The primary component within a bellows is the bellows element, which compresses to accommodate pipeline expansion and reduce stress. Conversely, as temperatures drop, the bellows expands to compensate for the pressure build-up, maintaining the structural integrity of the piping system.

Some applications may contain high flow velocities, which can induce severe vibration and lead to premature failure to the bellows element. The way to address this is to utilize a bellows expansion joint containing an internal sleeve, also known as a flow liner.

The bellows of an expansion joint is manufactured from relatively thin material in order to provide the flexibility needed to absorb the specified movement. The life of the Expansion Can be shortened if the unit is improperly handled and / or installed. This can arise from direct physical damage to the bellows through stresses imposed during installation, or by the factors. Therefore some basic instructions must be followed having safe and proper installation of Expansion joints.

There are several other things to consider when choosing whether or not to use a flow liner. Due to lateral movements, the gap between the bellows and the internal sleeve must be designed appropriately in order to prevent contact or binding against the inside diameter of the pipe or fitting. Also, making sure the inside diameter of the internal sleeve does not create back pressure or restrict the flow of media is extremely important, and usually can be avoided by utilizing an oversize bellows.

Stainless steel bellows, as a flexible pressure-resistant pipe fittings, are installed in the liquid transportation system to compensate for the mutual displacement of the connecting ends of pipes or machines and equipment, absorb vibration energy, and can play the role of vibration reduction and silencing. They have many characteristics, such as good flexibility, light weight, corrosion resistance, fatigue resistance, high and low temperature resistance.

| DN | Quantity of ripple | Pressure level | Effective area of corruagated tube | Maximum external diameter(mm) | ||||

|---|---|---|---|---|---|---|---|---|

| 0.25 | 0.6 | 1.0 | 1.6 | 2.5 | ||||

| Axial compensation length mm/toughness N/mm | ||||||||

| 32 | 8 | 25/21 | 22/26 | 20/26 | 18/63 | 16 | 225 | |

| 32 | 16 | 50/11 | 46/14 | 41/14 | 36/32 | 16 | 225 | |

| 40 | 8 | 25/25 | 22/44 | 20/44 | 18/89 | 15/98 | 23 | 244 |

| 40 | 16 | 50/14 | 46/22 | 41/22 | 36/45 | 31/47 | 23 | 244 |

| 50 | 8 | 25/30 | 22/51 | 20/70 | 18/70 | 15/106 | 37 | 259 |

| 50 | 16 | 50/16 | 46/26 | 41/35 | 36/35 | 31/55 | 37 | 259 |

| 65 | 8 | 33/28 | 30/35 | 26/44 | 22/55 | 15/138 | 55 | 270 |

| 65 | 12 | 42/16 | 38/22 | 38/32 | 34/40 | 31/70 | 55 | 270 |

| 80 | 8 | 40/20 | 36/26 | 34/33 | 28/41 | 19/68 | 81 | 284 |

| 80 | 10 | 53/14 | 49/17 | 49/21 | 43/26 | 29/50 | 81 | 284 |

| 100 | 6 | 45/47 | 45/60 | 40/75 | 35/93 | 25/54 | 121 | 304 |

| 100 | 10 | 76/26 | 74/32 | 64/40 | 57/50 | 38/33 | 121 | 304 |

| 125 | 5 | 48/38 | 42/47 | 38/59 | 34/74 | 29/117 | 180 | 334 |

Our expansion joint fabrications offer flexibility on the axial, lateral, or angular planes, depending on your needs. They are highly resistant to tension and compression within set parameters, providing you with safe, efficient, and reliable operation over the lifespan of the product.

Stainless steel bellows expansion joint is the compensating elements installed in pipelines, machines and containers, we often call it compensator.

Stainless steel bellows expansion joint mainly has three basic movement types: axial movement, lateral movement and angular movement. What’s the function of stainless steel bellows expansion joint? Generally speaking the functions are absorbing vibration, compensating movement and absorbing noise. Please check below detailed information.

On one hand, stainless steel bellows expansion joint can enhance the fatigue rupture capacity, on the other hand, it has function of reducing piping noise.

Take rubber hose as comparison, rubber hose has good flexibility and strong anti-fatigue ability, but it is inferior in temperature resistance, pressure bearing, aging resistance than stainless steel bellows expansion joint, it always needs to be changed after using a few months. While metal bellows owns comprehensive performances of out-standing corrosion resistance, temperature resistance, pressure resistance, fatigue resistance, in some complex environment, stainless steel bellows expansion joint is the most ideal element to compensate piping movements.

Typical installation problems always seen in some complex piping systems, the problems always caused by limitation of space and location. According to different pipeline diameter and working environment, the cold straightening value differs from several millimeters to dozens of millimeters, even hundreds of millimeters. Practise has proved that the larger of the cold straightening value, the higher of the internal stress, internal stress is a hidden danger to the pipeline system. Since stainless steel bellows expansion joint is able to bend freely and generate minimize internal stress in rated bending radius, thus, it is extremely convenient for installation, that’s the reason why stainless steel bellows expansion joint is the essential pipe fitting for some pipeline systems.

Metal bellows are elastic vessels that can be compressed when pressure is applied to the outside of the vessel, or extended under vacuum. When the pressure or vacuum is released, the bellows will return to its original shape (provided the material has not been stressed past its yield strength).

Expansion joints and metal bellows are vital components in a huge range of industrial settings. They play a vital role in equipment which needs to withstand high pressures, whether that is from gases or liquids. The units are designed to safely and reliably expand under pressure, and take prescribed temperatures in their stride. They can be formed from common metals such as stainless steel in various grades, and more exotic alloys such as Inconel can be used as per your requirements.

There are two main types of metal bellows – formed and welded. Formed bellows are produced by reworking tubes, normally produced by deep drawing, with a variety of processes, including cold forming (rolling), electroforming and hydroforming. They are also called convoluted bellows or sylphons.

Welded bellows (also called edge-welded, or diaphragm bellows) are manufactured by welding a number of individually formed diaphragms to each other. The comparison between the two bellows types generally centers around cost and performance. Hydroformed bellows generally have a high tooling cost, but, when mass-produced, may have a lower piece price. However, hydroformed bellows have lower performance characteristics due to relatively thick walls and high stiffness. Welded metal bellows are produced with a lower initial tooling cost and maintain higher performance characteristics. The drawback of welded bellows is the reduced metal strength at weld joints, caused by the high temperature of welding. Electroformed bellows can be produced with modest tooling costs and with thin walls (25 micrometres or less), providing them with high sensitivity and precision in many exacting applications.

Another area of comparison is in metals of construction. Hydroformed and rolled bellows are limited to metals with high plastic elongation characteristics, whereas welded bellows may be fabricated from a wider variety of standard and exotic alloys, such as stainless steel and titanium, as well as other high-strength, corrosion-resistant materials. Electroformed bellows can be produced of nickel, its high-strength alloys, and copper.

Bellows, welded or convoluted (formed) are used in a large number of industrial applications. Below you will find a few:

Load cells-A load cell deforms if a certain load in the form of a pressure or a strain is imposed on it. This deformation is then detected by a strain gauge through which a low voltage direct current is flowing. The change in voltage is detected and made visible on a control panel. A bellows is mounted over the gauge to protect it from outside influences.

Vacuum interrupters-For the switching of very high voltages in transformer stations sparks should be avoided. To prevent any danger that the surrounding atmosphere will explode, oxygen has to be removed in the area where the sparks occur. This can be done by sealing the spark area completely. Bellows are used to seal such confined volumes and the inside of the bellows is evacuated or filled with an inert gas.

Mechanical Seals-These are mostly used to close the inside of a pump from the outside world to prevent leakage. For that purpose, a mechanical seal is mounted on the pump shaft. As the pump shaft is turning, there has to be a sealing element consisting of a stationary and a rotating ring. To enforce sufficient pressure on the two rings one is fitted with a spring. This spring can also have the form of a diaphragm (welded) bellow.

Pressure gauges-If the pressure of aggressive fluids or gases has to be measured, the gauge has to be isolated from the flow. For critical applications a diaphragm sealing is used instead of a bourdon tube in the gauge. This gives more security that the aggressive media will not leak. The diaphragm is a self contained sensor, transmitting the displacement to the measuring device.

Sensors- In this application diaphragm or convoluted bellows are completely sealed and filled with a certain gas. Two electrical poles are penetrating the inside of the bellows. By varying the current of those two poles the temperature inside the bellows can be regulated. The expansion or contraction of the bellows is used as an actuator to control a certain movement.

Valve Sealing- A bellows is used between the housing and the rising stem to seal the inside completely from the outside world. In Europe this is of particular importance as regulations such as TA Luft prohibit any leakage.

Couplings for stepper motors and servomotors- The flexible part, capable of compensating for misalignment is made by a bellows. It ensures that there is no angular positioning difference between the two coupling halves. This is essential if the positioning accuracy should be extremely precise.

Exhaust Bellows- Running engines cause self vibration. To compensate for those movements and temperature differences resulting in thermal expansion, bellows are used to connect the exhaust gas pipes to the funnel.

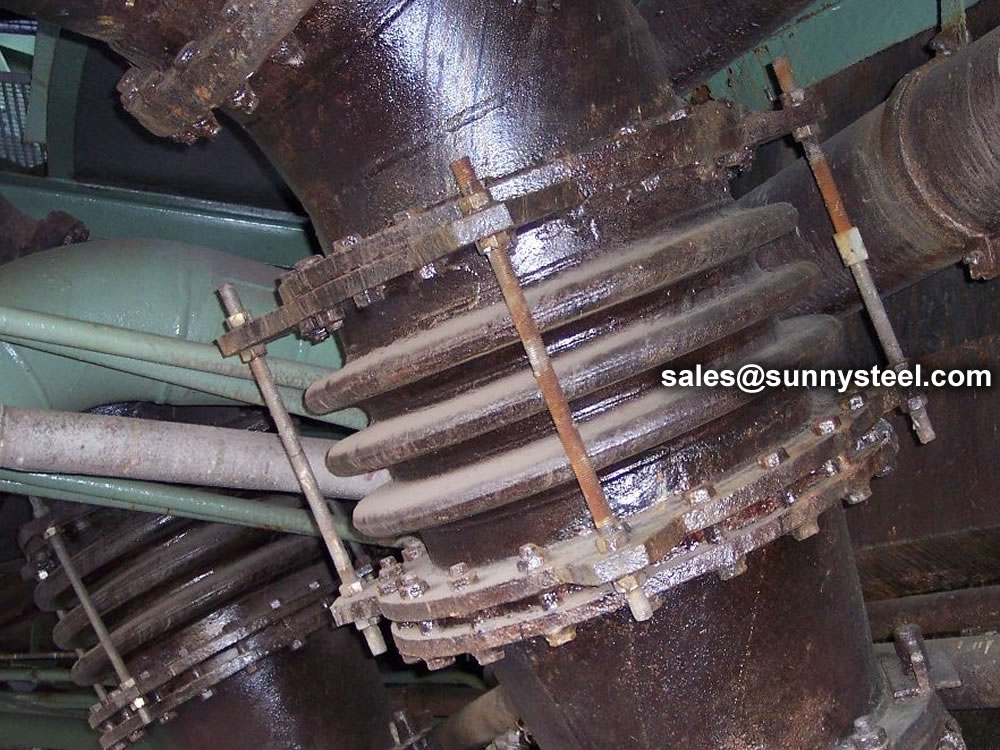

Piping expansion joint-In this application, bellows are formed in series to absorb thermal movement and vibration in piping systems that transport high temperature media such as exhaust gases or steam.

Metal bellows are also used in other products and market segments, including medical applications like implantable drug pumps, to industrial actuators, to aerospace applications such as altitude sensors and fluid management devices (accumulators, surge arresters, volume compensators, and fluid storage). Metal bellows are also found in space applications, providing reservoirs with potable water as well as accumulators to collect wastewater.

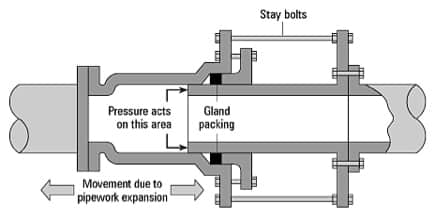

Expansion joints are devices containing a bellows membrane that are designed to absorb dimensional changes, such as those that occur due to thermal expansion or contraction of a pipeline, duct or vessel.

Expansion joints are devices containing a bellows membrane that are designed to absorb dimensional changes, such as those that occur due to thermal expansion or contraction of a pipeline, duct or vessel. The need to solve the problems of thermal expansion are not unique to anyone industry therefore expansion joints are used in a wide variety of market sectors specifically where there is a need to control the movement of pipelines due to changes in temperature. Thermal expansion problems can be solved where the natural flexing of the pipe is practical or where it is possible to install pipe loops however this is not always possible due to economic reasons or the design of modern structures are not capable of taking the loads of flexing pipework. In these situations the design engineer must seek an expansion joint solution.

Expansion joints come in two forms either restrained or unrestrained styles and although the bellows membrane incorporated in both styles look similar it is of great importance to recognize that they are used for entirely different applications.

Unrestrained expansion joints accommodate pipe movement by compressing and /or extending along their axis and hence they are also known as axial expansion joints. Axial expansion joints are very compact, adaptable and relatively inexpensive. Generally axial expansion joints are designed to accommodate movements between 25mm and 75mm however special bespoke expansion joints can be manufactured to suit specific site conditions. They must be suitably anchored and guided so as to prevent damage from the forces imposed on the pipework system. An installation with unrestrained expansion joints is called a non-pressure balanced solution

Restrained expansion joints are fitted with tie bars and / or hinges and therefore preventing the joint from moving axially. There are several expansion joint models that fall into the restrained group of expansion joints and are called Lateral, Fully Articulated, Hinged or Gimbal. The benefits of installing these types of expansion joints are that anchor forces are generally lower than installing unrestrained bellows and therefore savings can be made when selecting suitable anchors and guides. Restrained expansion joints are used in more complex pipe arrangements specifically on equipment where forces have to be kept to a minimum and, there is a requirement to take up large movements. Although retrained expansion joints are more expensive than unrestrained units significant cost savings on the total installation can be made due to reduced anchor and guide costs. An installation with restrained expansion joints is called a pressure balanced solution

Metallic expansion joints prevent damage from thermal expansion, vibration and other movements such as building settlement. Metallic expansion joints are generally manufactured from stainless steels or for more demanding environments or extreme conditions can be produced in materials such as Inconel, Incoloy, Hasteloy and Monel.

Expansion joints can also be produced from a variety of synthetic rubber materials such as ethylene propylene diene monomer (EPDM), Nitrile, Hypalon and Viton materials. Rubber expansion joints are primarily used on pumps, chillers and other reciprocating machinery to reduce noise and vibration. Whilst rubber bellows have the capabilities of compensating small amounts of axial, lateral and angular pipe work movement Sunny Steel always recommend a specifically designed metallic expansion joint to accommodate pipe movements when solving thermal expansion problems.

Expansion joints - sometimes called expansion bellows, flexible joints, compensators or movement joints. The variety of terminology for the same piece of equipment can be misleading. However expansion joints are designed to safely absorb dimensional movement changes and therefore the different names given to this critical unit are all related to its ability to accommodate a variety of movements such as expansion & contraction due to temperature difference, vibration due to reciprocating machinery, installation misalignment or building settlement.

At Sunny Steel, we offer a vast selection of expansion joints to serve a variety of purposes and are always on hand to provide you with accurate, high-quality advice whenever you require it. Our range of expansion joints includes axial, lateral, angular and gimbal joints. Our expansion joints are designed and calculated to the latest prevailing standards and pressure directives and therefore where applicable conform to latest Expansion Joint Manufacturers Association (EJMA) calculations. We reserve the right to make changes in the technical calculations without notice. All products are supplied with detailed installation and maintenance instructions where applicable to ensure your pipework system is fully in accordance with recommended engineering practice.

We oversee a large amount of stock, which ensures we can minimise downtime and respond to your requests quickly. We can supply joints with a bespoke flexible lagging jacket if needed. Why not contact us today if you do have any queries about the products that we supply? More and more discerning clients are heading straight to Sunny Steel when they do require expansion joints of the highest quality. We are renowned for only supplying products of the highest quality that do the job to the best standard possible and are more than happy to talk you through the options available so you can easily come to an informed decision and invest in the products that are right for you.

pipeline compensators are joints between sections of pipe that move, expand and contract to compensate for pressure caused by thermal changes, vibration from machinery and misalignment. Expansion joints are often referred to as compensators, expansion bellows or flexible joints and can be used in a variety of applications, including transfer sections near boilers, engines, turbines, condensers, pumps or heat exchangers.

Expansion joints can be made from a variety of materials depending on the application. Metal bellows are one of the most common and useful types of expansion joint, but rubber, fabric and plastics (such as PTFE) are also used in various circumstances. To ensure that the correct type of expansion joint is used for your application, it is essential that an engineer with experience in this field is consulted prior to implementation.

An expansion joint for piping is a flexible component used in piping systems to accommodate thermal expansion, contraction, vibration, and movement. It is designed to absorb the stress and movement caused by temperature changes, preventing damage to the piping system.

When selecting an expansion joint, factors like temperature range, pressure rating, material compatibility, and movement capacity should be carefully assessed. Safety is of paramount importance, and expansion joints should be inspected regularly to ensure they are in proper working condition.

Compensator reliability is by the design, manufacture, installation and operation and management and other aspects of the composition. Reliability should also be considered from these aspects.

Material Selection For the selection of corrugated pipe for heating pipe network, in addition to considering the working medium, working temperature and the external environment, the possibility of stress corrosion should also be considered, the impact of water treatment agent and pipe cleaning agent on the material, etc.,

Based on this, the corrugated pipe material is welded and formed, and the cost performance of the material is optimized. The economical and practical corrugated pipe material is selected.

For the laying of the heat pipe network, when the compensator is located in the lower pipelines, rain or accidental sewage will soak corrugated pipe, should consider the use of more corrosion-resistant materials, such as iron-nickel alloy, high-nickel alloy. Due to the high price of such materials, it may be advisable to add a corrosion-resistant alloy only to the surface in contact with the corrosive medium when making the bellows.

In a piping system a Expansion joints alternately known as Bellows are like sealed springs. Sealed because it is required to contain the fluid pressure which is flowing through it and spring because it is required to respond to the movement of the connected piping without offering appreciable stiffness to the piping system.

An expansion joint/bellow element employed in a piping system is an assembly of generally more than one convolute in series. The convolutes are designed strong enough to withstand the internal pressure of the system, at the same time the typical contour of the convolute assembly allow sit to flex under thermal movement of the connected piping. As a result of this extreme flexibility the expansion joint / bellow as such is highly incapable of absorbing any longitudinal loads by its own,thereby requiring external attachments to transfer these longitudinal loads to its connected piping for maintaining the overall stability of the piping system under question.

However should site conditions demand a unique solution then end connections can be adapted to most applications.

The terms can be confusing since there is no universally accepted meaning. We usually use the following definitions, but the terms “bellows” and “expansion joint” are generally considered interchangeable:

Pipe expansion joints are also known as compensators, as they ‘compensate’ for the thermal movement.

Pipe expansion joints are necessary in systems that convey high temperature commodities such as steam or exhaust gases, or to absorb movement and vibration. A typical type of expansion joint for pipe systems is a bellows which can be manufactured from metal (most commonly stainless steel), plastic (such as PTFE), or an elastomer such as rubber.

A bellows is made up of a series of one or more convolutions, with the shape of the convolution designed to withstand the internal pressures of the pipe, but flexible enough to accept the axial, lateral, and/or angular deflections. Expansion joints are also designed for other criteria, such as noise absorption, anti-vibration, earthquake movement, and building settlement.

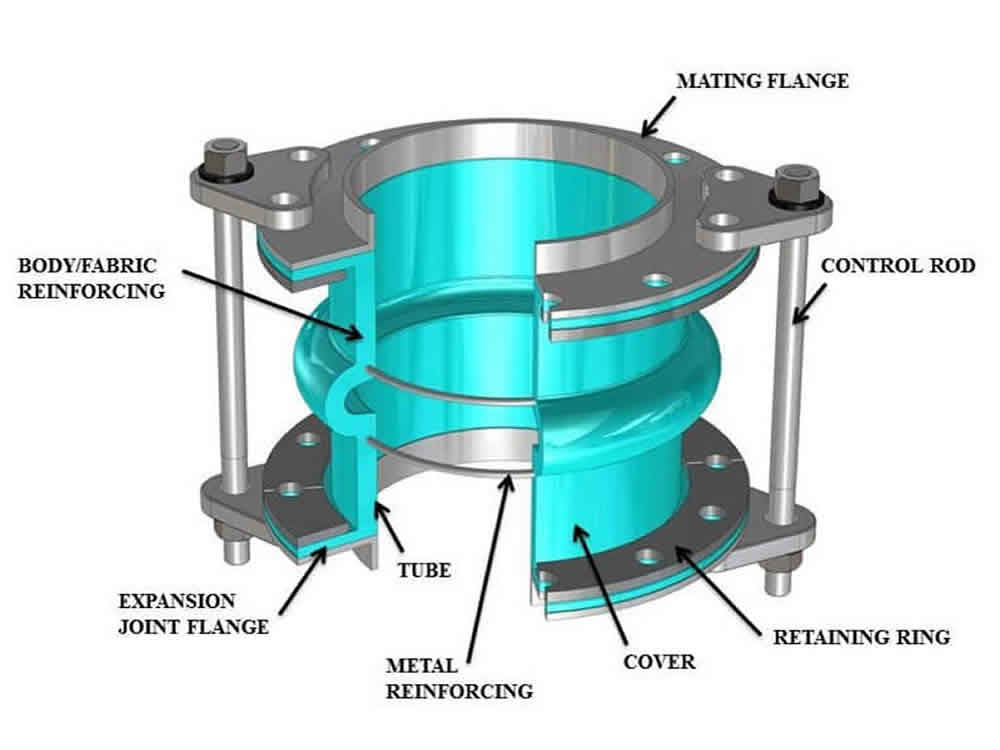

Tube – A protective, leak proof lining made of synthetic or natural rubber. The tubes primary function is to eliminate the possibility of materials being handled penetrating the carcass.

Carcass – The carcass or body of the expansion joint consists of fabric, and when necessary metal.

Cover – The exterior surface of the joint.

Fabric Reinforcement – The carcass fabric reinforcement is the flexibility and supporting member between the tube and cover.

Metal Reinforcement – Wire or solid steel rings imbedded in the carcass, often used for strengthening.

Retaining Ring – Used to compress the expansion joint flange to the mating flange to create a seal. Also called clamp bars or backing bars. Applies to most all expansion joints.

Mating Flange – Used to connect the pipe joint to the pipe in which it is being installed.

Control Rod – Used to limit the axial movements during operation, and prevent the joint from exceeding its movement capabilities. The rods attach the mating flange and expansion joint. Typically used on piping joints, but can be installed on most any joint when required.

Expansion joints are an assembly designed to safely absorb sound, expansion, con traction and vibration to ensure expansion jointsthat the application stays in fully working order.

When we apply this technique to pipe systems, we brand the term ‘pipe expansion joint’ or ‘bellows’.

These pieces of equipment are used in pipe work where movement, thermal expansion and much more could cause problems. The pipe expansion joints are made up from one or more convolutions, which are designed to move or expand to relieve the stress from the solid pipe. The amount of movement or expansion within the application will determine the number and shape of convolutions required. Expansion joints can be manufactured from a range of different materials, from stainless steel and PTFE, to rubber.

Pipe expansion joints are also designed for other criteria, such as noise absorption, anti vibration, earthquake movement and building settlement. Metal expansion joints have to be designed according to rules. Pipe expansion joints are used in a number of industries, including; oil, petrochemical and paper industries.

Pipe expansion joints are often manufactured to withstand temperatures from minus 300°F, up to 4000°F, as well as being able to resist at full vacuum or 2000 psig. Expansion joints can be manufactured from a range of different materials aforementioned. Before the introduction of pipe expansion joints, engineers were battling with the task of combating problems regarding thermal expansion, corrosion and abrasive factors that took effect on the functionality of various applications. Fabric joints can be used in a number of applications for turbines and pipelines, which can defend against resistance, heat and a range of other environmental factors.

Pipe expansion joints are crucial components in the pipe technology sector, which serve a huge number of industries. They are used to counterbalance length changes that generally occur in pipelines from temperature changes and can also absorb vibrations. It is a cost effective solution to increase the life span, reliability and costs of many applications through equipment and process management.

Accessories are added to an expansion joint installation to meet specific customer, application or code requirements. Some are used to control movement, others to protect the bellows in the event of pressure thrust, and still others to defend against corrosion caused by media inside or from the environment outside the bellows.

Divide piping into two separate segments insuring proper movement of each bellows in double type expansion joint.

Used in conjunction with internal sleeve to:

Internal liners can be used to either protect the metallic bellows from erosion or reduce turbulence across the bellows. They must be used when purge connectors are included in the design. In order to provide enough clearance in the liner design, appropriate lateral and angular movements must be specified by the designer. When designing an expansion joint with combination ends, flow direction must be specified as well.

External covers should be used to protect the internal bellows from being damaged. They also serve a purpose as insulation of the bellows. Covers can either be designed as removable or permanent accessories.

In systems that have a media with significant particulate content (i.e. flash or catalyst), a barrier of ceramic fiber can be utilized to prevent corrosion and restricted bellows flexibility resulting from the accumulation of the particulate. Purge connectors may also be utilized to perform this same function. Internal liners must also be included in the design if the expansion joint includes purge connectors or particulate barriers.

Limit rods may be used in an expansion joint design to limit the axial compression or expansion. They allow the expansion joint to move over a range according to where the nut stops are placed along the rods. Limit rods are used to prevent bellows over-extension while restraining the full pressure thrust of the system.

Pipe expansion joints are necessary in systems that convey high temperature commodities such as steam or exhaust gases, or to absorb movement and vibration.

An expansion joint is a useful component in an infinite number of applications.

A bellows is made up of a series of one or more convolutions, with the shape of the convolution designed to withstand the internal pressures of the pipe, but flexible enough to accept the axial, lateral, and/or angular deflections.

Expansion joints are also designed for other criteria, such as noise absorption, anti-vibration, earthquake movement, and building settlement.

Engineers and pipe designers routinely incorporate expansion joints into their pipe systems, as expansion joints add flexibility in to the design and reduce costs through removing the complexity of fix points, guides and reduces the overall space requirements for the pipe system.

Further, expansion joints are more effective than alternatives such as pipe bends and pipe loops due to their greater ability to conserve space, their economic efficiency and better performance in absorbing larger movements.

Inner plastic film packing, outer standard export wooden case packing.

Courier company transport, air freight and sea transport. It depends on your actual order details and quantity.

Our team of experienced sales specialists proudly partners with gas and chemical processors, power generation plants, oil refineries, and related industries to offer piping components and value-added services.

Q: How can you guarantee the quality or any warranty?

A: Check the specification, material and appearance before delivery, and approve the delivery after qualified.

B: Support third-party inspection.

Q: What can we do for you?

A: we support OEM/ODM,we can provide drawings,technical support,installation maintenance.

Q: Can you provide samples?

A: Yes, we generally provide samples with a diameter of 100 or less, and you need to bear the freight of the samples

Q:What information do I need to provide if I want an accurate quote.

A: Please confirm the product, material, working pressure, connection method, flange standard, medium and quantity.

Q: Do you accept small quantity order?

A: Of course we do.

Q:what are your payment term?

A: After receiving T/T 30% payment, start production; Remaining 70% paid before delivery

Q: Where is your nearest loading port?

A: Shanghai, Qingdao or Tianjin, China.

Q: When is your shipping and delivery time?

A: By sea or air. Normally 7 to 14 Days for delivery, according to your order quantity.

An expansion joint is a useful component in an infinite number of applications. Metal expansion joint assemblies are commonly used for all kinds of industries and applications including:

Expansion joints are often installed near boilers, heat exchangers, pumps, turbines, condensers, engines and in long pipe systems or pipe ducts.

Expansion joints come in a wide variety of designs. Some of them are standard and some are customised as per client requirements.

Although their design may vary significantly, all expansion joints are nevertheless composed from some of the following components, all with one or more specific functionalities: bellows, welding ends, flanges, hinges, tie-rods, spherical washers, wire mesh, insulation, inner sleeve, external cover, elbow and/or ring reinforcement/equalizing rings.

In general, there are fabric, metallic, and rubber expansion joints.

In a piping system a Expansion joints alternately known as Bellows are like sealed springs. Sealed because it is required to contain the fluid pressure which is flowing through it and spring because it is required to respond to the movement of the connected piping without offering appreciable stiffness to the piping system.

The Bellows are generally employed in a piping system in one of the following situations:

An expansion joint or movement joint is an assembly designed to safely absorb the heat-induced expansion and contraction of construction materials, to absorb vibration, to hold parts together, or to allow movement due to ground settlement or earthquakes.

They are commonly found between sections of buildings, bridges, sidewalks, railway tracks, piping systems, ships, and other structures.

Expansion joints – sometimes called expansion bellows, flexible joints or Expansion joint – are devices that comprise of a flexible element known as the bellows membrane that is fitted to end connections that are best suited to the pipework they are to be installed in.

Most bellows membranes are manufactured from stainless steel and are made up of a series of convolutions manufactured to withstand the pressure of the system but also must be suitable to accept the movements for which they are designed. The bellows membrane comprises of a series of convolutions designed to withstand the internal pressures of the system, but at the same time flexible enough to accept axial, lateral and angular deflections.

The joint needs to be a highly resistant nature so it’s necessary to make sure that it’s far thicker than you’d expect. In turn, this slows down any effects of potential corrosion as although it may be affected by the elements over time, it will still retain its density.

Expansion joints are required in large ducted air systems to allow fixed pieces of piping to be largely free of stress as thermal expansion occurs.

Bends in elbows also can accommodate this.

Expansion joints also isolate pieces of equipment such as fans from the rigid ductwork thereby reducing vibration to the ductwork as well as allowing the fan to “grow” as it comes up to the operating air system temperature without putting stress on the fan or the fixed portions of ductwork.

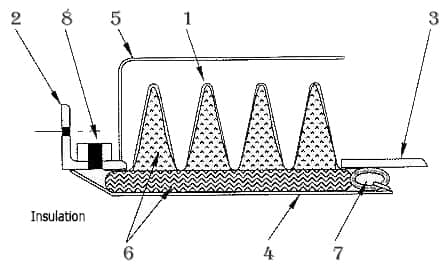

An expansion joint is designed to allow deflection in the axial(compression) or laterally (shear) or angular (bending) deflections. Expansion joints can be non-metallic or metallic (often called bellows type). Non-metallic can be a single ply of rubberized material or a composite made of multiple layers of heat and erosion resistant flexible material.

Typical layers are: outer cover to act a gas seal, a corrosion resistant material such as Teflon, a layer of fiberglass to act as an insulator and to add durability, several layers of insulation to ensure that the heat transfer from the flue gas is reduced to the required temperature and an inside layer.

A bellows is made up of a series of one or more convolutions of metal to allow the axial, lateral or angular deflection required.

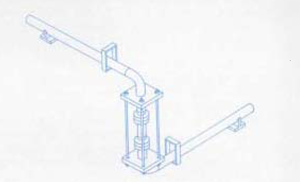

Tied universal expansion joints are frequently used to absorb lateral deflection in a “Z” bend configuration. The expansion joint absorbs the thermal movement ol horizontal pipelines as lateral defleclion. This can be accomplished in a single plane or three plane configuration. In a three plane “Z ” bend the horizontal pipes may lie at any angle in the horizontal plane since the tied universal expansion joint can absorb lateral deflection in any direction.

Expansion joints are used in all kinds of different sectors and in a huge range of different industrial contexts.

Specific industries that use expansion joints include the Energy sector such as nuclear power plants and district heating schemes.

Essentially, wherever there is a need to control pipework movement expansion joints are required. They are used in factories and power plants wherever thermal expansion needs to be controlled, such as pipelines that connect with condensers or power turbines. They are used in oil and fuel gas applications.

The Petrochemical industry on oil refineries, pumping stations and oil rigs.

Civil engineering, waste management, sewage treatment, recycling, water treatment, aerospace, aviation, defence, the automotive industry, agriculture, mining, metals manufacturing, food and dairy manufacturing and packaging, and so on.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.