Nipo Flange

Nipoflange is a connection that has a flange on one side and a Nipolet on the other side.

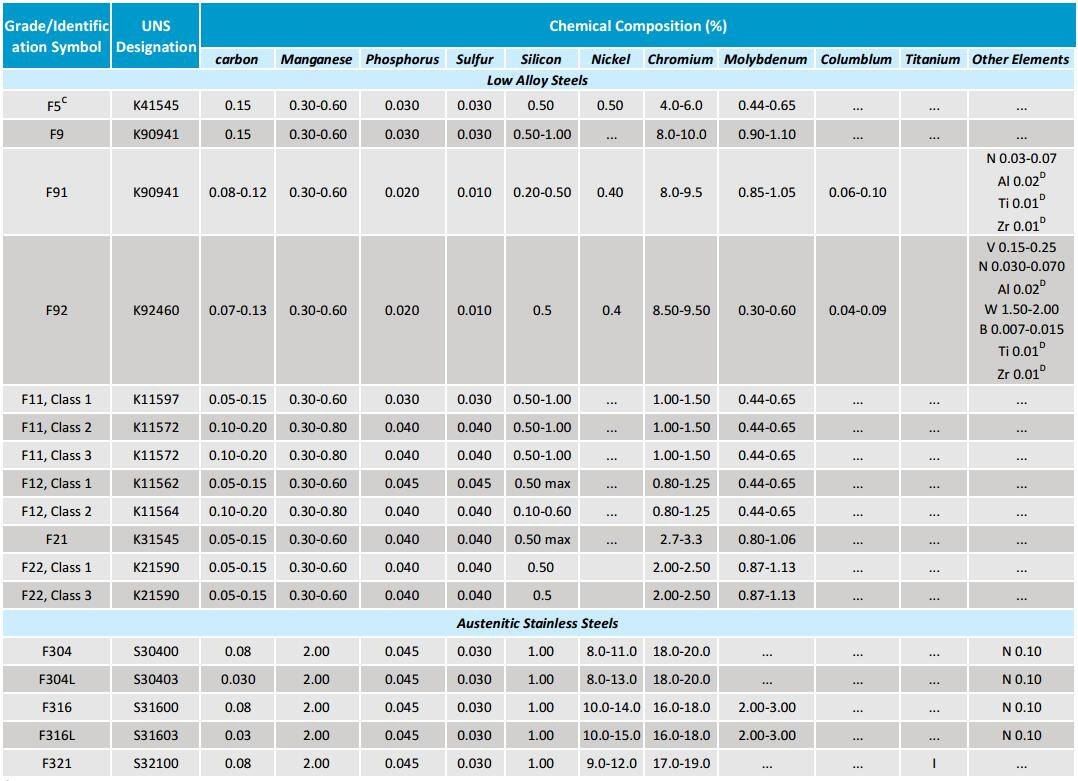

ASTM A182/A182M Standard Specification for Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-Temperature Service.

Download PDFASTM A182/A182M is a vital specification for forged or rolled alloy and stainless steel components used in high-temperature applications. Its coverage of material types, mechanical properties, and applications makes it essential for industries requiring reliable and durable piping solutions.

ASTM A182/A182M is a standard specification established by ASTM International for forged or rolled alloy and stainless steel piping components, specifically designed for high-temperature service. This specification outlines the materials, manufacturing processes, and mechanical properties to ensure performance in various applications within the chemical, petrochemical, and power generation industries.

ASTM A182 standard specification is for forged and rolled alloy and stainless steel pipe flanges, fittings, valves and parts for high temperature service. Common grades of alloy steel is Grade F5, F9, F11, F22, stainless steel F304/L and F316/L.

The standard applies to forged low alloy steel and stainless steel pipe parts for use in pressure systems. These include flanges, fittings, valves and similar parts that meet specified size or size standards. And it includes several grades of low carbon alloy steel and ferritic, martensitic, austenitic and ferritic-austenitic stainless steels. So it should be selected according to the design and use requirements.

When additional tests or inspections are required, supplementary requirements are provided for use. When the purchaser has specified them individually in the order, and it can be used.

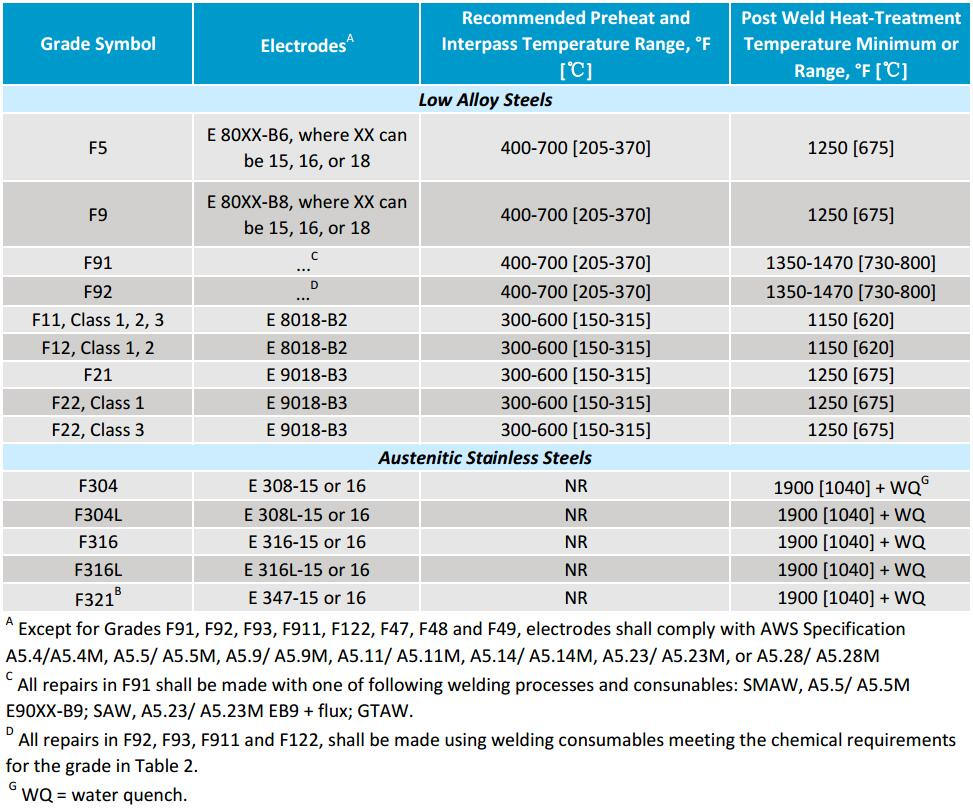

Alloy grade: ASTM A182 F5, F9, F91, F92, F11, F12, F21, F22

Stainless steel grade: ASTM A182 F304, F304L, F316, F316L

ASTM F11, F22 is the most use alloy steel grade in ASTM A182.

ASTM A182 F316 is most used for stainless steel flange, includes weld neck flange, slip on flange, blind flange, socket weld flange and etc.

Either alloy steel or stainless steel flange dimensions available for the OD up to 48 inch, class pressure from 150# to 2500#.

This specification is expressed in inch-pounds and SI units.

Low alloy ferritic steels should be smelted in one of the following methods:

a. Open hearth furnaces

b. Electric furnaces

c. Basis -oxygen process (with the option of separate degassing and refining processes).

Stainless steel should be smelted in one of the following ways:

a. Electric furnace (with separate deoxidation and refining (optional))

b. Vacuum furnace

c. One of the above, followed by vacuum or electroslag self-consumption remelting.

The discard should be removed sufficiently, so as to ensure the elimination of harmful shrinkage and excessive segregation.

Chemical heat analysis shall be performed and consistent with the chemical composition requirements of Table 1.

Grades that add lead, selenium or other elements to make the material easier machined, it should not be used.

It is not permissible to add any element that exceeds the corresponding material grade listed in Table 2 for the raw materials produced in accordance with a certain standard.

Except for nitrogen in stainless steel, the ordered grade shall not contain unspecified elements to the extent that the content meets the requirements of another grade, which have the specified element with the minimum required content.

C: The present grade F 5a (0.25 max carbon) previous to 1995 eas assigned the identification symbol F 5. Identification symbol F 5 in 1955 was assigned to the 0.15 max carbon grade to be consistent with ASTM soecification for other products such as pipe, tubing, bolting, welding fittings, and the like.

D: Applies to both heat and product analysises.

I: Grade F 321 shall have a titanium content of not less than five times the carbon content and not more than 0.70%.

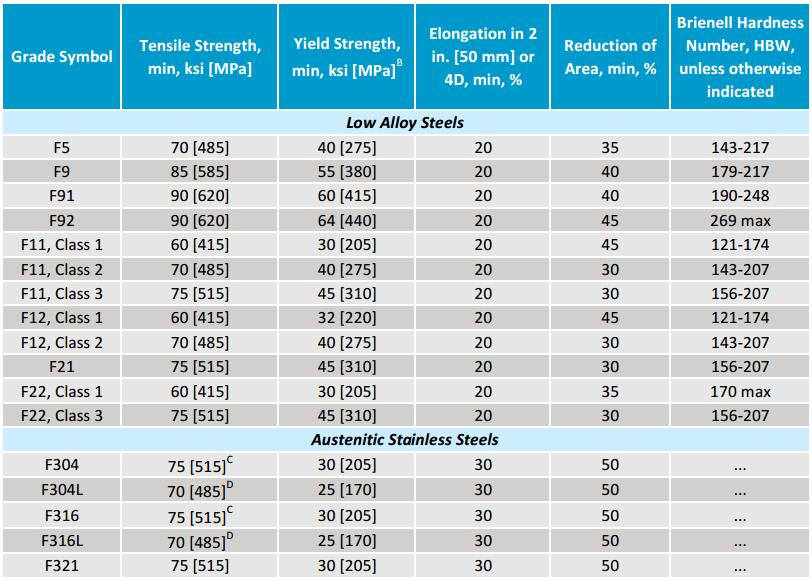

For the grade ordered as listed in Table 2, the mechanical properties of the material shall comply with the requirements.

Table 2:

C: For sections over 5 in. [130 mm] in thickness, the minimum tensile strength shall be 70 ksi [485 MPa].

D: For sections over 5 in. [130 mm] in thickness, the minimum tensile strength shall be 65 ksi [450 MPa].

For low alloy steel, ferritic and martensitic stainless steel, one tension test shall be performed for each heat in each heat treatment charge.

When the heat treating cycle are the same and the furnace is controlled within ±25°F[±14℃]. And it is equipped with a recording pyrometer, so as to obtain a complete heat treatment record. However, only one tensile test is performed for each heat of each forging type and section size, rather than the per heating in each heat treatment charge.

If the results of the mechanical properties test do not meet the specified requirements, and the forgings may be performed heat treatment again. Meanwhile the mechanical properties test should comply with requirement.

For hollow forgings of grades F91, F92, F122 and F911, greater than or equal to NPS 4 (DIN 100). The inner surface of which cannot be inspected by magnetic particle or liquid penetration, the ultrasonic inspection shall be carried out in accordance with A388 / A388M.

If the inner surface is accessible, it shall be examined by the magnetic particle in accordance with regulation A275/A275M, or by the penetration test according to test method E165.

The material should be forged as close to the actual specified shape and size as possible.

Elbows, U-bends, tees, connecting tees and any type of flange should not be processed directly from bars.

Cylindrical shaped parts can be machined using forged or rolled solution annealed austenitic stainless steel without the need for additional thermal processing.

Cylindrical shaped low-alloy, martensite, ferrite and ferrite-austenitic stainless steel parts that less than or equal to NPS-4 [DN 100], may be machined using forged or rolled bars without additional hot processing.

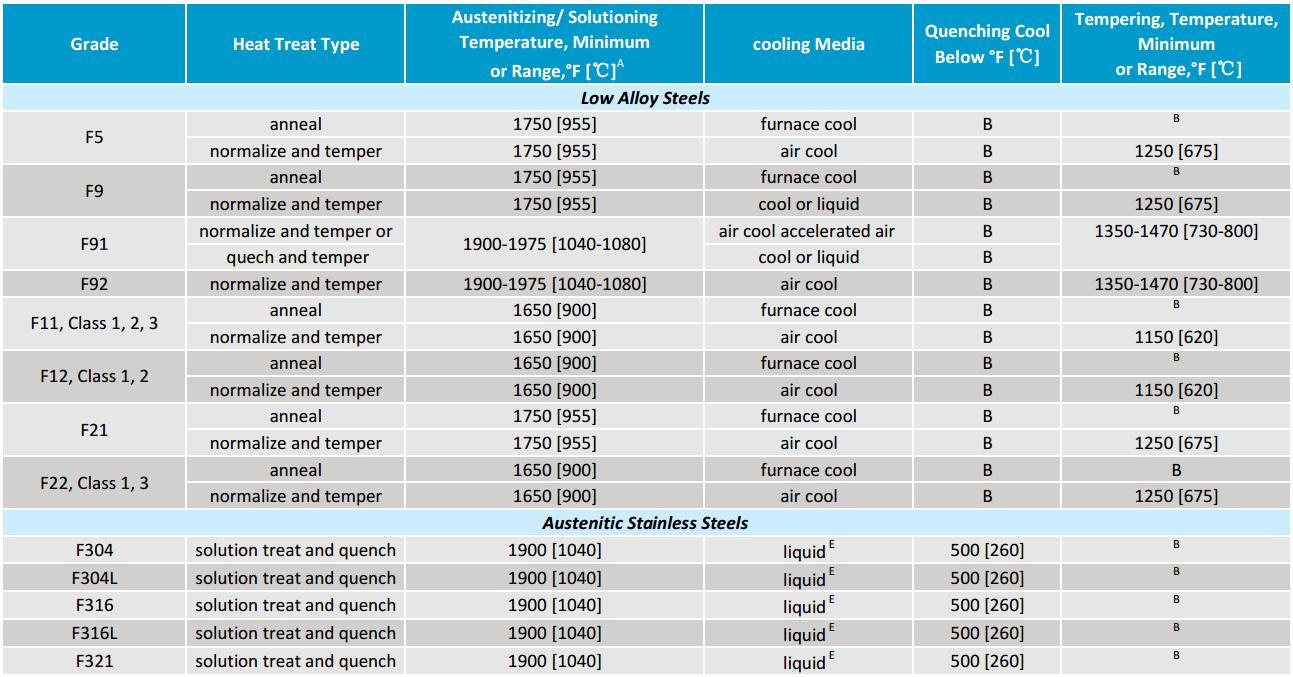

After hot working, and the forgings shall be cooled to a temperature less than 1000 °F [538 ℃] before heat treatment as specified in Heat treatment Table 3.

Table 3:

A: Minimum unless temperature range is listed

B: Not applicable

E: Forged or rolled bar meeting the requirements of 7.5 shall be liquid quenched or rapid-cooled by other means in accordance with Specification A484/ A484M

Low-alloy steels, ferritic and martensitic stainless steels shall be heat-treated in accordance with table 3. When more than one heat treatment is listed (optional) for a grade in table 3, any one of these is acceptable. The choice of heat treatment should be determined by the manufacturer, unless otherwise specified in the order.

Except for F1, F2 and F3 in 3.2.2, if the temperature of each grade in Table 3 is used with the consent of purchaser. So the liquid should be allowed to quench, then tempered.

Marking

Parts that are liquid quenched and tempered, and shall be marked with the letter ''QT''.

In addition, grades F1, F2 and F12, Class 1 and 2 can be done a heat treatment with a minimum temperature of 1200°F, (650℃) after final cold or hot forming.

Austenitic and ferritic-austenitic stainless steels shall be heat treated and liquid quenched in accordance with Table 3.

Heat treatment of forgings can be carried out before machining.

Forged or rolled austenitic stainless steel rods for cylindrical shaped parts as specified in mechanical properties requirement. And the parts machined from bar without heat treatment after processing. It shall comply with annealing and quenching or rapid cooling requirements of A484 / A484M or this specification, and also allows for subsequent light cold drawing and straightening.

Forgings and finished parts shall be free of scale and machined burrs that may interfere with installation, and other harmful defects as referred to in this standard. They shall have good processing quality, and the roughness of machined surfaces (except for special requirements) shall not exceed 250AA (arithmetic mean).

ASTM A182 F304 Stainless Steel Flanges are components made from stainless steel alloy containing chromium and nickel. These components are usually circular in shape with an opening in the center, which is also known as a bore. The edges of this disc-shaped component have raised surfaces that mate with other similar components or pipes to create a secure connection between two pipes or other pieces of equipment. ASTM A182 F304 Stainless Steel Flanges are essential components that are used in a wide range of applications. From the automotive industry to construction, these flanges can be found in many places due to their durability and strength.

These types of flanges have several applications across various industries. For example, they can be found in the automotive industry, where they provide connections between exhaust systems and catalytic converters. In addition, these flanges can be found in industrial piping systems for transporting liquids such as oil or gas, as well as air conditioning systems and refrigeration units. Other common uses include water treatment plants, chemical plants, food processing facilities, and more.

The primary benefit of using these types of flanges is their durability and strength compared to other types of metals, such as aluminum or copper. These materials can handle higher temperatures without corroding or becoming brittle like aluminum or copper would do when exposed to extreme temperatures or pressures. In addition to their strength and durability, these materials also resist corrosion better than other materials, making them ideal for environments where there is a high risk of corrosion, such as marine settings or near coastal areas. Also, they have excellent heat transfer properties, which makes them ideal for transferring heat from one component to another while still maintaining their structural integrity over time.

There are several types of Stainless Steel 304 Flanges available, including slip-on welded-neck socket welded threaded reducing, and lap joint varieties, among others. All different types serve different purposes depending on the specific application. ASTM A182 F304 Stainless Steel Flange offers a variety of benefits, including superior strength and durability compared to other metals, making it an ideal choice for many industries, Additionally, they have excellent heat transfer properties making them suitable for transferring heat from one component to another while still maintaining their structural integrity over time.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.