Erosion Shields

Erosion Shields are designed to eliminate major maintenance and downtime costs from boiler and condenser tube failure.

Steel repair sleeves are an ideal option for maintenance needs as they allow repairs to be made without shutting down the pipeline.

Download PDF

Steel Repair Sleeves are critical components for reinforcing pipelines affected by corrosion, dents, and other anomalies. Manufactured from high-quality structural or pressure vessel steel, these sleeves ensure the durability and safety of pipelines without the need for line shutdowns, offering a reliable repair solution that meets ASTM specifications and enhances the service life of pipelines.

The steel repair sleeves are sold in the half sole configuration and can be used for internal and external corrosion, dents, grooves, arc burns, cracks, defective girth welds, laminations and leaks.

We manufacture half pipe sleeve of all sizes, wall thickness, and grades of steel plates which are to ASTM certifications as well as a longitudinal edge. Half-sole repair sleeves also called as spilt casting or half wrap are manufactured by customizing as per client’s specification.

Depending on the requirements of the customer, half pipe sleeve can be made from 4 available grades of steel. For instance, for leaking & non-leaking defects, pressure-rated steel sleeves are used whereas structural grade steel sleeves are used for reinforcement for a defective area.

Steel repair sleeves are an ideal option for maintenance needs as they allow repairs to be made without shutting down the pipeline. The steel repair sleeves are sold in the half sole configuration and can be used for internal and external corrosion, dents, grooves, arc burns, cracks, defective girth welds, laminations and leaks.

Milled grooves for backing strips are available. If a custom Milled Groove size is required, we can accommodate those needs.

The half repair sleeve is a versatile component used in pipeline maintenance and repair to reinforce damaged sections and ensure the integrity of the pipeline.

Pressure containing sleeves feature a wall thickness equal to or greater than required for the maximum allowable operating pressure or the full strength of the pipe being repaired. The half repair sleeve material is certified and the carbon equivalent will not exceed 0.45 percent. Each half-sole segment comes with one pre-crimped back-up strip. Half pipe sleeves can be used as pads or cradles for above ground piping, drain tile supports and patches (segments in 90° and 180° arcs, from 6-inches to 10 feet in length are available as specials). Each Half pipe sleeve has standard bevels with a back-up strip and material certifications. Sleeve ends are square cut.

The steel repair sleeves can be used for internal and external corrosion, gouges, dents, grooves, arc burns, cracks, defective girth welds, laminations and leaks.

Pressure containing sleeves feature a wall thickness equal to or greater than required for the maximum allowable operating pressure or the full strength of the pipe being repaired. The steel Repair sleeve material is certified and the carbon equivalent will not exceed 0.45 percent. Each half-sole segment comes with one pre-crimped back-up strip.

Steel Repair Sleeves can be used as pads or cradles for above ground piping, drain tile supports and patches (segments in 90° and 180° arcs, from 6-inches to 10 feet in length are available as specials).

Each Steel Repair Sleeve has standard bevels with a back-up strip and material certifications. Sleeve ends are square cut. Back-up strip are not included with Standard Girth Weld Steel Repair Sleeves but are available as special order.

The half pipe sleeves can be used in case of leaks, dents, corrosion, cracks & faulty girth welds. Every repair sleeve are provided with standard bevels with a backup strip.

Material used are structural quality carbon steel or pressure vessel quality carbon steel plates, which are to ASTM specifications, and in the following grades:

The chemical composition does not exceed the percentages specified for the ASTM material ordered. Repair sleeves are fabricated from plate with low carbon equivalency for good weld ability.

The maximum allowable carbon equivalency (CE) quality carbon steel plates will be based on the heat analysis.

The maximum allowable carbon equivalency (CE) pressure vessel quality carbon steel plates will be based on the heat analysis, in most cases.

Note: The sleeve can be manufactured in any grade as per the application & client requirements.

Our half pipe sleeve are manufactured from the best quality carbon steel material. We pride ourselves on making the half sole by rolling, die forming and step braking and they never undergo heat treating. Thus making our expertise & technique best in the industry. If a client specifically asks for longitudinal edges of the half pipe sleeve to be beveled for welding, it can be done. Half pipe sleeves ends have shaved square edges to enable fillet welding, although square end bevel can also be made as per client specification. Our for repair sleeves are made with carbon steel plates with low carbon equivalency to ensure good weld ability.

Half Pipe Sleeve can be milled on the inside longitudinal edges for the backing strips. Depth of 1/16″ (.0625) -0″ + 1/32″ and width of 5/8″ (.625) -0 + 1/16″ on each side. Outside longitudinal edges are beveled 30° (+5° – 0° ) for welding.

Backing Strips

Backing strips are hot rolled commercial carbon steel sheet and strip of commercial quality, A-569/A1011 SS GR33 in coils and cut lengths having a maximum carbon of 0.15%. 1 1/4″ wide, 16 gauge (.0598) with a tolerance of: min..0538 – max. 0658, 10′ long, pre-crimped (10 degree total bend).

All of our sleeves are manufactured from quality, carbon steel material, all of which are up to ASTM/ASME specifications. We keep copies of material test reports on file and verify heat numbers prior to producing all parts.

We can manufacture half pipe sleeve in any custom steel grades and of any size as per the application & requirement of the customer.

Inspection Of Half Pipe Sleeves

Every half sleeve is meticulously examined and inspected for defects before delivery. The shipment is thoroughly tested and verified for durability and stability.

Our quality experts first review the entire shipment of half pipe sleeves before we dispatch them to our clients. Parts that do not meet our strict standards are rejected and not shipped.

Mill test reports will be furnished on all materials. Stock plate is not available with a maximum hardness guarantee. Independent testing may be performed to check the hardness on stock plate. Additional independent testing available to include: destructive, magnetic particle, liquid penetrate, ultrasonic and radiographic.

Longitudinal edges are beveled to 30 degrees (+5 degrees -0 degrees), with a root face (land) of 1/16″ (+-1/32″). This will be a mechanical type bevel or by plasma torch burning. Beveled ends are available upon request. Inside diameter of each Half Pipe Sleeve is fabricated to match the outside diameter of standard nominal line pipe. Half Pipe Sleeve are manufactured so that when two halves of the sleeve are placed on the pipe, their total circumference shall equal the circumference of the pipe minus a gap between the longitudinal edges on either side of 1/16″ (-1/16″+1/32″) for welding.

Every half sleeve pipe is marked for the size, thickness, dimension & grade of steel before shipping across India & abroad. Any half sleeve pipe not meeting the requirements for visual inspection or dimensional tolerance are rejected.

Half pipe sleeves are designed to avoid costly shutdowns. Existing lines can be cased with no loss of throughput, as there is no need to shut down the carrier line to make the required repair.

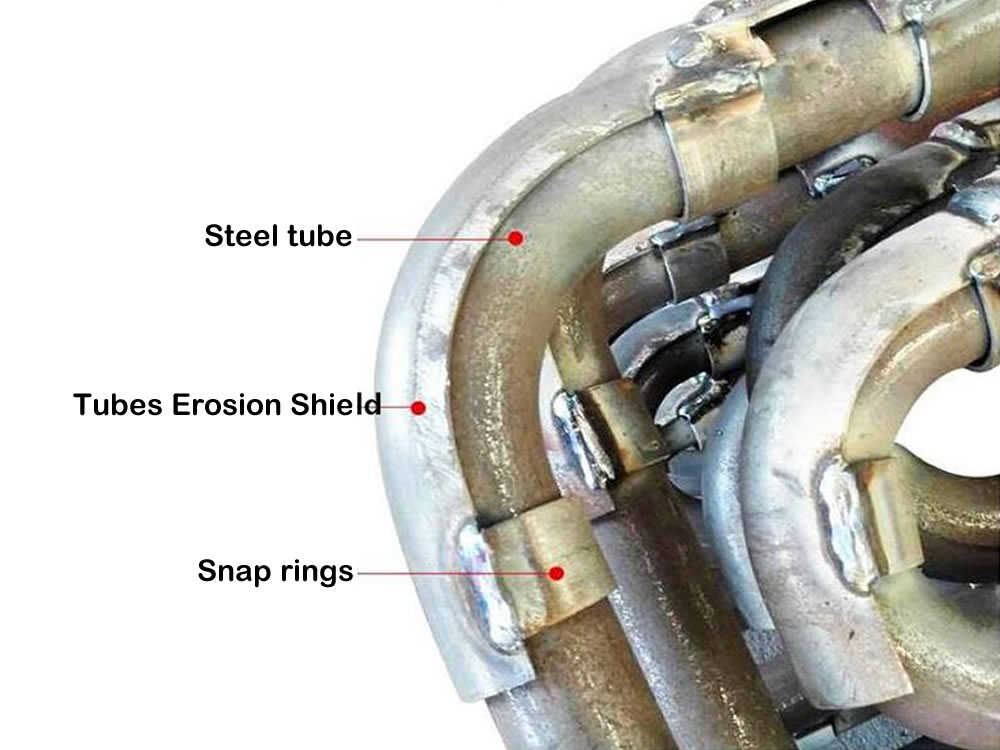

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.

The snap ring is a short section that is installed on the pipe in conjunction with the wear-resistant tile. Generally, it is welded to the wear-resistant tile by lap welding, that is, to cover the wear-resistant tile slightly, so it is larger than the wear-resistant tile. The opening arc is around 190-200 degrees, the welding position needs to be set aside to facilitate welding and fixing. The width of the snap ring must not be less than 20mm.

The installation requirements of anti-friction tiles of different shapes are slightly different. Basically, each anti-friction tile is installed with not less than 2-4 snap rings. The snap ring and the anti-friction tile are welded together to prevent expansion due to heat. The tiles fall off, and the joints are required to be fully welded.

Generally, boiler tubes erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosion.

The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.

When you partner with Sunny Steel, you can stop worrying about meeting deadlines thanks to our responsive and timely service. You'll also say goodbye to unnecessary shopping around. Instead, you'll get white glove service from an expert who understands your needs and can get you the materials you need quickly.