Discover the advantages and various applications of food grade rubber expansion joints in the food industry.

Learn how they ensure safety and flexibility while accommodating different processing needs. Find reliable suppliers for your food-grade expansion joint requirements.

Download PDFFood grade rubber expansion joints play a crucial role in the food processing industry, providing essential benefits that ensure safety and efficiency during various processing operations. These specially designed expansion joints are made from high-quality food-grade rubber materials, making them suitable for use in environments where hygiene and sanitation are of utmost importance.

Food grade rubber joints with SS316 flanges is generally consist of the inner and the outer rubber layer and fabric reinforced layer (the enhancement layer has a multilayer spreading cord fabric), vulcanization molded in high temperature and high pressure , then assembly together with rubber tube and metal flange or parallel joint sleeve.

Discover the benefits of using food grade rubber expansion joints in the food processing industry. Learn how these flexible and hygienic joints ensure safety and efficiency in various processing operations. Find out how they accommodate movement, prevent contamination, and contribute to seamless food production.

Hygienic Design: Food grade rubber expansion joints are crafted with materials that meet strict sanitary requirements, preventing the growth of bacteria and other harmful microorganisms. This ensures that the food processing environment remains safe and contaminant-free.

Flexibility and Movement: These expansion joints are designed to accommodate movement, vibration, and thermal expansion within the food processing system. They help prevent damage to pipelines, pumps, and other equipment by absorbing the stress caused by dynamic operating conditions.

Resistance to Chemicals and Abrasion: Food-grade rubber materials used in the expansion joints offer excellent resistance to chemicals and abrasion, making them durable and long-lasting in harsh processing environments.

Easy Maintenance: Food grade rubber expansion joints are easy to install and maintain, reducing downtime and operational costs in the food processing facility.

Food and Beverage Processing: These expansion joints are widely used in food and beverage processing plants to maintain hygienic conditions, support equipment movement, and ensure smooth operations during various stages of production.

Dairy Industry: Food grade rubber expansion joints are crucial in dairy processing facilities to handle the movement and pressure fluctuations in milk and other dairy product pipelines.

Breweries and Wineries: Expansion joints are vital in breweries and wineries to accommodate the temperature changes during fermentation and the movement of liquid between different vessels.

Pharmaceutical Industry: In pharmaceutical manufacturing, these expansion joints are employed to maintain a sterile environment and prevent cross-contamination during the production of drugs and medications.

Cosmetic and Personal Care Products: Food grade rubber expansion joints are used in the production of cosmetic and personal care items to maintain a clean and contamination-free manufacturing environment.

Food grade rubber expansion joints offer a reliable solution for ensuring safety, flexibility, and efficiency in food processing operations. When choosing a supplier, look for reputable manufacturers that meet industry standards and have a proven track record of delivering high-quality products.

Whether you require expansion joints for a food processing facility, brewery, or pharmaceutical plant, finding a trusted supplier is essential. Ensure the seamless flow of your food processing operations with premium food grade rubber expansion joints.

1.Outstanding pressure resistance

It excels in pressure resistance by the combination of spherical structure with super stability against internal pressure and strong special reinforcing nylon. We flexible connector display an outstanding pressure resistance of bursting pressure.

2.Superior absorption of vibration-noise-shock

We single sphere flexible rubber joint are engineered to reduce vibration ,noise and movenment inherent in piping systems.Joint installation of the We will enable the isolated equipment to move freely ,eliminating vibration and repelling sound which is prevalent in metallic type joint.

3.Compensate greater elongation, compression , lateral and angular movement

Equipment such as pump ,chillers,cooling tower,compressors and piping systems move out of alignment due to wear,load stress and during the setting of foundation blocks.We flexible connector for lateral ,torsional and angular movement to prevent damage ,which elimate costly downtime in plant operation.

Stainless steel flange connection white sanitary food grade silicone rubber expansion joint is mainly used in food pipe field, such as transport juice, drinks and wine etc. The flange is usually stainless steel, the rubber is food grade silicone rubber, size range from DN25 to DN600, working pressure is usually PN6~PN40, working temperature range from -15 ~ +80 celsius degree, the flange standard could be DIN, ANSI and JIS, in addition, we could do OEM and ODM work, stick your brand logo on rubber body, mark your brand name on flange. This white rubber expansion joint is also called white rubber joint, white expansion joint, white flexible connection, sanitary rubber joint and so on.

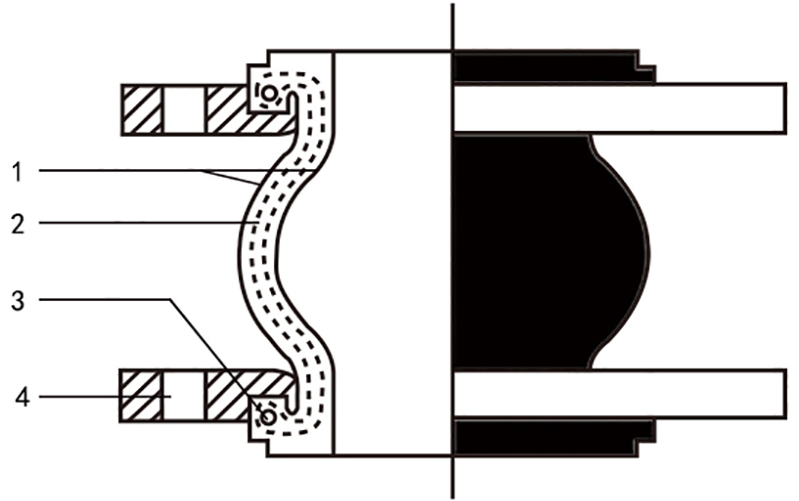

| No. | Name | Material |

| 1 | Inner and outer layer | Food grade silicone rubber |

| 2 | Frame | Nylon fabric cord |

| 3 | Stabilizing ring | Steel wire strand |

| 4 | Flange | Stainless steel 304 or 316 or 321 |

Keywords: food grade rubber expansion joint, food processing, hygienic design, flexibility, resistance to chemicals, easy maintenance, food and beverage processing, dairy industry, breweries, wineries, pharmaceutical industry, cosmetic, personal care products

Food processing is a critical industry that demands the highest standards of safety and hygiene. Manufacturers and processors strive to maintain a clean and contaminant-free environment to ensure the quality and integrity of their products. One crucial component in this endeavor is the food grade rubber expansion joint. In this comprehensive guide, we will explore the many advantages and applications of these specialized expansion joints in the food industry.

A food grade rubber expansion joint is a specialized flexible connector used in food processing systems. It is made from high-quality rubber materials that comply with stringent food industry standards to ensure safety and hygiene. These joints allow for movement, vibration, and thermal expansion, preventing damage to pipelines and equipment.

The hygienic design of food grade rubber expansion joints is crucial in food processing facilities. They prevent the growth of bacteria and other harmful microorganisms, ensuring a clean and safe environment for food production.

Food grade rubber expansion joints accommodate movement and vibration within the food processing system, preventing stress and damage to pipelines and equipment. They enable seamless and efficient operations, even in dynamic conditions.

These expansion joints offer excellent resistance to chemicals and abrasion, making them ideal for use in harsh processing environments. They maintain their integrity and longevity, even when exposed to aggressive substances.

Food grade rubber expansion joints are designed for easy installation and maintenance, reducing downtime and operational costs in food processing facilities. Their user-friendly features streamline maintenance tasks.

In food and beverage processing plants, these expansion joints support various stages of production. They maintain hygienic conditions and ensure efficient material flow during processing.

The dairy industry relies on food grade rubber expansion joints to handle the movement and pressure fluctuations in milk and other dairy product pipelines. These joints ensure the integrity of dairy production processes.

Food grade rubber expansion joints are vital in breweries and wineries, accommodating temperature changes during fermentation and the movement of liquids between different vessels.

The pharmaceutical industry uses these expansion joints to maintain a sterile environment and prevent cross-contamination during the production of drugs and medications.

In the production of cosmetic and personal care items, food grade rubber expansion joints contribute to a clean and contamination-free manufacturing environment.

Choosing the right expansion joint for specific food processing needs requires considering factors such as operating conditions, temperature, pressure, and the type of materials being processed.

Proper installation and regular maintenance are crucial for the optimal performance of food grade rubber expansion joints. Following manufacturer guidelines and conducting routine inspections ensure their longevity and efficiency.

Food processing facilities may encounter challenges related to expansion joint wear, contamination, and leakage. Understanding these challenges and implementing appropriate solutions is essential for uninterrupted production.

As technology advances and industry requirements evolve, the development of innovative food grade rubber expansion joints will continue to meet the ever-changing demands of the food processing sector.

Q: How can food grade rubber expansion joints prevent contamination? A: Food grade rubber expansion joints are crafted with materials that inhibit the growth of harmful microorganisms, ensuring a hygienic environment.

Q: Are food grade rubber expansion joints suitable for high-temperature processing? A: Yes, these expansion joints are designed to withstand high temperatures encountered in various food processing operations.

Q: What maintenance tasks are involved in caring for food grade rubber expansion joints? A: Regular inspections, cleaning, and checking for wear are essential maintenance tasks to ensure the longevity of these expansion joints.

Q: Can food grade rubber expansion joints handle harsh chemicals? A: Yes, these joints offer excellent resistance to chemicals, making them suitable for use in environments with aggressive substances.

Q: Are food grade rubber expansion joints easy to install? A: Yes, these expansion joints are user-friendly and designed for easy installation in food processing facilities.

Q: Can I use food grade rubber expansion joints for beverage processing? A: Yes, these joints are versatile and suitable for use