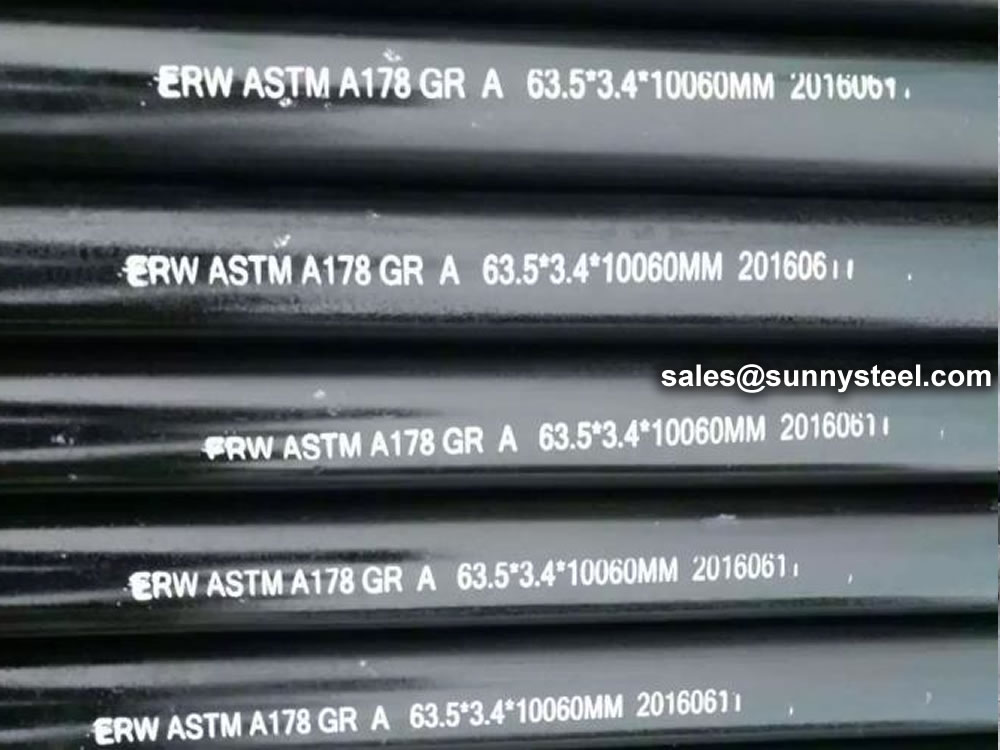

ASTM a178/A 178M Standard Specification for Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater Tubes.

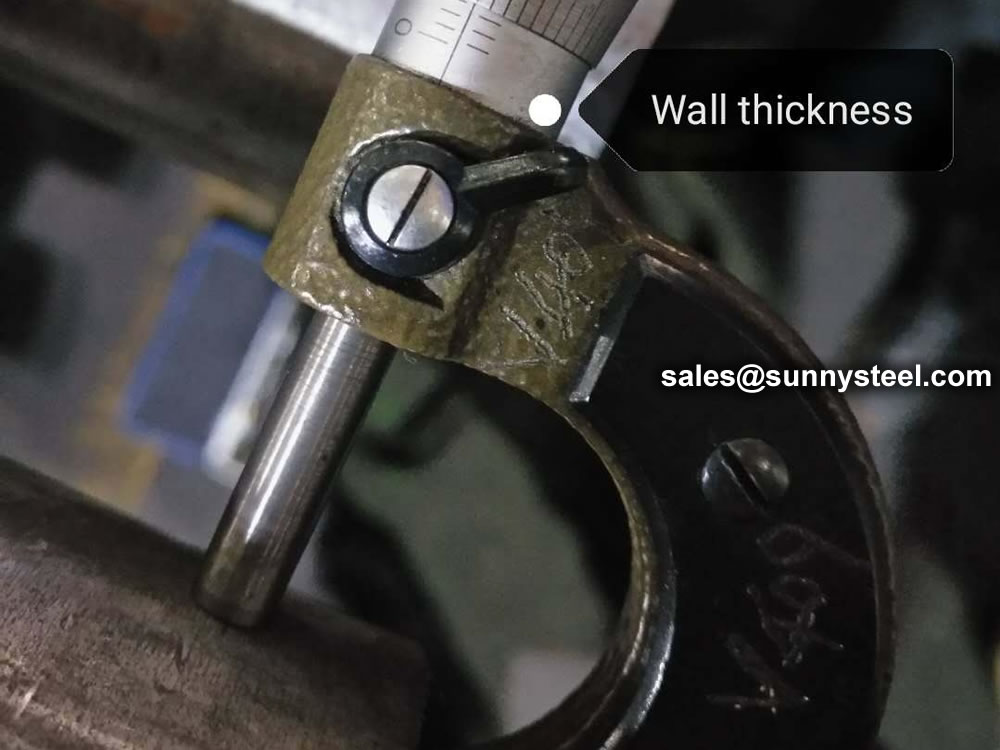

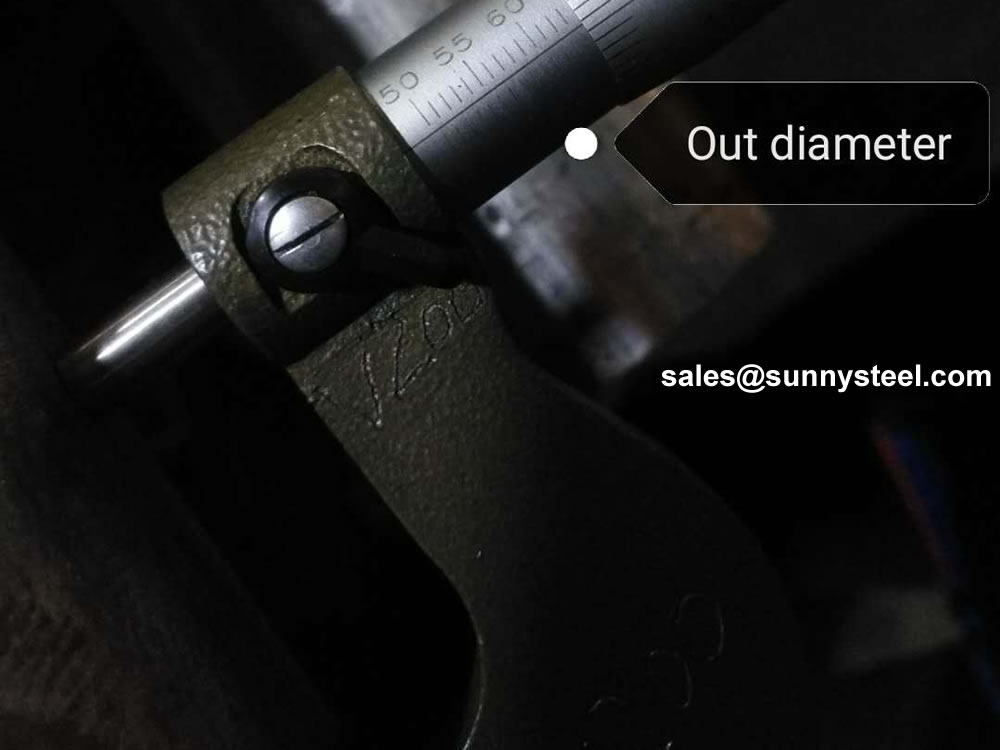

1.1 This specification2 covers minimum-wall-thickness, electric-resistance-welded tubes made of carbon steel and carbon-manganese steel intended for use as boiler tubes, boiler flues, superheater flues, and safe ends.

1.2 This specification covers Grades A, C, and D with differing chemical requirements (Section 6 and Table 1), differing tensile requirements (Section 9 and Table 2), and differing crush and mechanical testing requirements (Sections 10 and 11).

NOTE 1: Grades C and D tubes are not suitable for safe-ending for forge welding.

1.3 The tubing sizes and thicknesses usually furnished to this specification are 1/2 to 5 in. [12.7 to 127 mm] in outside diameter and 0.035 to 0.360 in. [0.9 to 9.1 mm], inclusive, in minimum wall thickness. Tubing having other dimensions may be furnished, provided such tubes comply with all other requirements of this specification.

1.4 Mechanical property requirements do not apply to tubing smaller than 1/8 in. [3.2 mm] in inside diameter or 0.015 in. [0.4 mm] in thickness.

1.5 Optional supplementary requirements are provided and when desired, shall be so stated in the order.

1.6 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. The inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Condenser steel tube,heat-exchanger tube,low carbon steel pipe,Resistance welded steel tube ,Bolier flues,Spoerheater flues and safe ends,ERW carbon steel pipes.

| Element % | ASTM A178 Gr A / SA178A | ASTM A178 Gr C / SA178C | ASTM A178 Gr D / SA178D |

| Low carbon steel | Medium Carbon Steel | Manganess Steel | |

| C | 0.06-0.18 | 0.35 Max | 0.27 Max |

| Mn | 0.27-0.63 | 0.80 Max | 1.00-1.50 |

| P | 0.035 | 0.035 | 0.030 |

| S | 0.035 | 0.035 | 0.015 |

| Si | ... | ... | 0.10 Min. |

Grade C & Grade D tubes shall conform to the requirements -tensile properties prescribed below

| Item | ASTM A178 Gr A / SA178A | ASTM A178 Gr C / SA178C | ASTM A178 Gr D / SA178D |

| Tensile strength, min, ksi [MPa] | 47[325] | 60[415] | 70[485] |

| Yield strength, min, ksi [MPa] | 26[180] | 37[255] | 40[275] |

| Elongation in 2 in. or 50mm, min, % | 35 | 30 | 30 |

| For longitudinal strip tests a deduction for | 1.50A | 1.50A | 1.50A |

| Each1⁄32-in[0.8mm] decrease in wall thickness below 5⁄16in. [8mm] | |||

| From the basic minimum elongation of the following percentage points shall be made |

| Outside Diameter tol | Wall thickness tol | ||

| OD < 50 | ±0.05mm | S < 4mm | ±12.5% |

| OD > 50 | ±1% | 4--20mm | +15/-12.5% |

| S≧20mm | ±12.5% | ||

ASTM A450 covers carbon and low alloy steel tube. Steel samples shall be melt processed and shall either be ingot cast or strand cast. Heat and product analyses shall be performed on the steel materials. Steel specimens shall also undergo tensile tests and shall conform to required values of yield strength and elongation. Flattening test, reverse flattening test, flaring test, flange test, hardness test, hydrostatic test, air underwater pressure test, and nondestructive tests shall be performed on the steel materials.

Heat treatment:

After welding,all tubes shall be heat treated at a temperature of 1650°F(900℃) or higher and followed by cooling in air or in the cooling chamber of a controlled-atmosphere furnace,Cold-drawn tubes shall be heat treated after the final cold-draw pass at a temperature of 1200°F(650℃)or higher.

Surface Condition:

Finished tubes shall be free of scale,A slight amount of oxidation will not be considered as scale.

Mechanical Tests Required:

Flattenting Test/Flaring test/Flange test/Crush test/Tension test/Reverse Flattening test/Hydrostatic or Nondestructive Electric Test

Used in boiler, superheater, heat-exchanger and pressure equipment in Petrochemical factory, Refinery factory, sugar mill, power plant, power plant, shipbuilding.

The ASTM A178 Grade D steel shall be killed. ASTM A178 tubes shall be made by electric-resistance welding process. After welding, all tubes shall be heat treated at a temperature of 1650°F [900°C] or higher and followed by cooling in air or in the cooling chamber of a controlled-atmosphere furnace. Cold-drawn tubes shall be heat treated after the final cold-draw pass at a temperature of 1200°F [650°F] or higher.

ERW tubes made from ASTM A178 steel may be tested or inspected in the following ways covering crush test, flattening test, flange test, tension test, reverse tension test, hydrostatic test, nondestructive electric test, dimension inspection, visual examination, as well as ultrasonic inspection.

A 178 C-Steel Electric-Resistance-Welded Boiler Tubes

| ASTM STANDARD |

UNS NO. | KOREA/JAPANES | GERMAN | BRITISH | BELGIAN | FRENCH | ITALIAN | |||||||||||||

| KS/JIS Symbol | KS/JIS Numbe | Remarks | DIN Type | DIN Number |

Materiral Number |

Remarks | B.S Number |

B.S Grade | NBN Type | NBN Grade | Remarks | AFNOR Type | NF Number | Ramarks | UNI Type | UNI Number | Ramarks | |||

| Graade A | K01200 | STBH 340 / STB 35 | D3563 / G3461 | St 37.8 | 17177 | 1.0315 | (7) | 3059 | ERW 320 | (3) | (3) | |||||||||

| Grade c | K03503 | SHBH 410 / STB 42 | D3563 / G3461 | St 42.8 | 17177 | 1.0498 | (7) | (3) | (3) | |||||||||||

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Casting | API 5CT | Ø48.3~273 x WT2.77~11.43 | J55, K55, N80, L80 |

| Tubing | API 5CT | Ø48.3~273 x WT2.77~11.43 | J55, K55, N80, L80, H40 |

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Line Pipes | API 5L | Ø60.3~273.1 x WT2.77~12.7 | A25, A, B, X42, X46, X52, X56, X60, X65, X70, X80 |

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Electric-Resistance-Welded Steel Pipes | ASTM A135 | Ø42.2~114.3 x WT2.11~2.63 | A |

| Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater Tubes | ASTM A178 | 42.2-114.3 x 2.11-2.63 | A, C, D |

| ERW and Hot-dip Galvanized Steel Pipes | ASTM A53 | Ø21.3~273 x WT2.11~12.7 | A, B |

| Pipes for Piling Usage | ASTM A252 | Ø219.1~508 x WT3.6~12.7 | Gr.2, Gr.3 |

| Tubes for General Structural Purpose | ASTM A500 | Ø21.3~273 x WT2.11~12.7 | Gr.2, Gr.3 |

| Square Pipes for General Structural Purpose | ASTM A500 | 25 x 25~160 x 160 x WT1.2~8.0 | Carbon Steel |

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Threaded Steel Pipes | DIN 2440 | Ø21~164 x WT2.65~4.85 | Carbon Steel |

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Screwed and Socketed Steel Tubes | BS 1387 | Ø21.4~113.9 x WT2~3.6 | Carbon Steel |

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Scaffolding Pipes | EN 39 | Ø48.3 x WT3.2~4 | Carbon Steel |

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Carbon Steel Tubes for General Structure Purpose | JIS G3444 | Ø21.7~216.3 x WT2.0~6.0 | Carbon Steel |

| Carbon Steel Tubes for Machine Structure Purpose | JIS G3445 | Ø15~76 x WT0.7~3.0 | STKM11A, STKM13A |

| Carbon Steel Pipes for Ordinary Piping | JIS G3452 | Ø21.9~216.3 x WT2.8~5.8 | Carbon Steel |

| Carbon Steel Pipes for Pressure Service | JIS G3454 | Ø21.7~216.3 x WT2.8~7.1 | Carbon Steel |

| Carbon Steel Rigid Steel Conduits | JIS G8305 | Ø21~113.4 x WT1.2~3.5 | G16~G104, C19~C75, E19~E75 |

| Carbon Steel Rectangular Pipes for General Structure | JIS G3466 | 16 x 16~150 x 150 x WT0.7~6 | Carbon Steel |

The alloy content of the coil is often lower than similar grades of steel plate, improving the weldability of the spiral welded pipe. Due to the rolling direction of spiral welded pipe coil is not perpendicular to the pipe axis direction, the crack resistance of the spiral welded pipe materials.

Welded steel pipe refers to a steel pipe with seams on the surface that is welded by bending and deforming a steel strip or steel plate into a circular, square or other shape. The blanks used for welded steel pipes are steel sheets or strips.

Since the 1930s, with the rapid development of continuous rolling production of high-quality strip steel and the advancement of welding and inspection technology, the quality of welds has been continuously improved, and the varieties and specifications of welded steel pipes have been increasing.

When the T-shaped welded steel pipe contains Ni, it has strong corrosion resistance in an acidic environment. In an environment containing sulfuric acid or hydrochloric acid, the higher the Ni content in the T-shaped welded steel pipe, the stronger the corrosion resistance. Under normal circumstances, only adding Cr to the T-shaped welded steel pipe can prevent the phenomenon of corrosion. The poor edge condition of the strip is another important cause of misalignment. The effects of changes in mass flow, heat flow density and structural parameters (ratio of helical curvature diameter to T-shaped welded steel pipe diameter Dc/D) on the heat transfer coefficient of saturated bubble boiling in vertical spiral pipes.

During the production of T-shaped welded steel pipes, misalignment occurs from time to time, and there are many influencing factors. In production practice, the steel pipe is often degraded by the wrong side and out of tolerance. Therefore, it is necessary to analyze the reasons for the misalignment of the spiral steel pipe and its preventive measures.

Due to the poor shape and dimensional accuracy of the head and tail of the uncut steel strip, it is easy to cause the steel strip to bend hard and cause misalignment during butt joint. Simulation parameter range: vertical pipe: pipe diameter D=10mm, pipe length L=660mm; three types of vertical T-shaped welded steel pipe: pipe diameter D=10mm, the change of the ratio of the curvature diameter of the T-shaped welded steel pipe to the spiral pipe diameter is Dc /D=15, 20, 25, helical pitch Pt=20mm, tube lengths are L=503mm, L=660mm, L=817mm respectively. Mass flow G=200~400Kg/(m'2 s), heat flux density q=5~15KW/m'2, saturation pressure p, saturation=0.414880MPa, saturation temperature T, saturation=283.15K.

The technical requirements and inspection of welded pipes are based on the provisions of the GB3092 "Welded Steel Pipes for Low-Pressure Fluid Transmission". It can be delivered according to fixed length or double length. The surface of the steel pipe should be smooth, and defects such as folds, cracks, delamination, and lap welding are not allowed. The surface of the steel pipe is allowed to have minor defects such as scratches, scratches, weld misalignment, burns and scars that do not exceed the negative deviation of the wall thickness. The thickening of the wall thickness and the presence of inner seam weld bars are allowed at the weld.

Welded steel pipes should be subjected to mechanical performance test, flattening test and flaring test, and must meet the requirements of the standard. When the steel pipe should be able to withstand the internal pressure, carry out a pressure test of 2.5Mpa, and keep it for one minute without leakage. The method of eddy current flaw detection is allowed to replace the hydrostatic test. The eddy current flaw detection is carried out according to the standard of GB7735 "Steel tube eddy current flaw detection inspection method". The eddy current flaw detection method is to fix the probe on the frame, keep a distance of 3~5mm between the flaw detection and the weld seam, and conduct a comprehensive scan of the weld seam by the rapid movement of the steel pipe. The flaw detection signal is automatically processed and sorted by the eddy current flaw detector. To achieve the purpose of flaw detection. The welded pipe after the flaw detection is cut off according to the specified length with a flying saw, and it is rolled off the assembly line through the turning frame. Both ends of the steel pipe should be chamfered with flat ends, printed with marks, and the finished pipes are packed in hexagonal bundles before leaving the factory.

Straight seam steel pipe is a steel pipe whose weld seam is parallel to the longitudinal direction of the steel pipe. Generally, its strength is higher than that of straight seam welded pipe. Narrower billets can be used to produce welded pipes with larger diameters, and the same width of billets can be used to produce welded pipes with different pipe diameters. But compared with the straight seam pipe of the same length, the weld length is increased by 30~100%, and the production speed is lower. So what are its processing methods?

The surface quenching and tempering heat treatment of straight seam welded pipe is usually carried out by induction heating or flame heating. The main technical parameters are surface hardness, local hardness and effective hardened layer depth. Vickers hardness tester can be used for hardness testing, and Rockwell or superficial Rockwell hardness tester can also be used. When the surface heat treatment hardened layer is thick, the Rockwell hardness tester can also be used. When the thickness of the heat-treated hardened layer is 0.4-0.8mm, the HRA scale can be used, and when the thickness of the hardened layer exceeds 0.8mm, the HRC scale can be used.

If the parts require high local hardness, local quenching heat treatment can be carried out by means of induction heating. Such longitudinal welded pipes usually need to mark the location of local quenching heat treatment and local hardness value on the drawing. Hardness testing of longitudinally welded pipes shall be carried out in the area. The hardness testing instrument can use a Rockwell hardness tester to test the HRC hardness value. If the heat-treated hardened layer is shallow, a surface Rockwell hardness tester can be used to test the HRN hardness value.

The three hardness values of Vickers, Rockwell and Superficial Rockwell can be easily converted to each other and converted into hardness values required by standards, drawings or users. The corresponding conversion tables are given in the international standard ISO, the American standard ASTM and the Chinese standard GB/T.